A method of back grouting for subway tunnel wall

A technology of tunnel wall and post-grouting, applied in tunnels, tunnel lining, earthwork drilling, etc., can solve the problem of high leakage risk of buried pipes, and achieve the effects of good sealing, high strength and high connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

[0043] A post-grouting method for a subway tunnel wall, comprising a grouting step and a sealing step, and the thickness of the segment 5 of the subway tunnel is 35 mm;

[0044] The grouting steps are as follows:

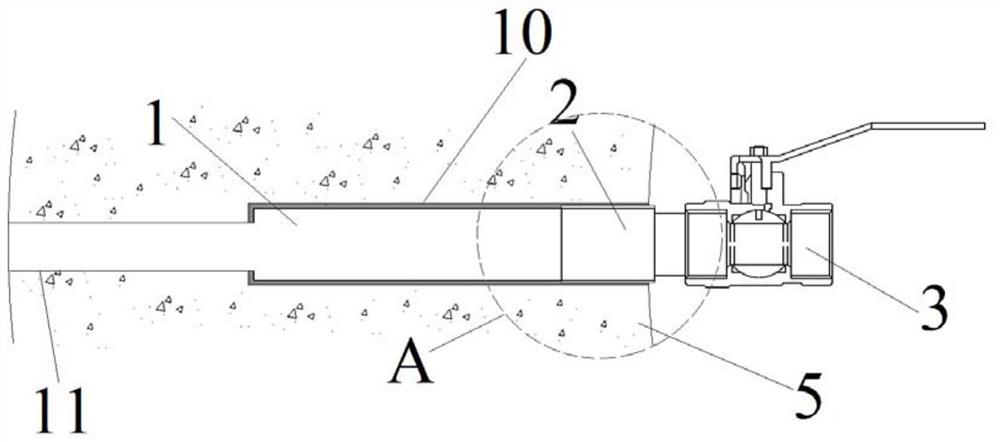

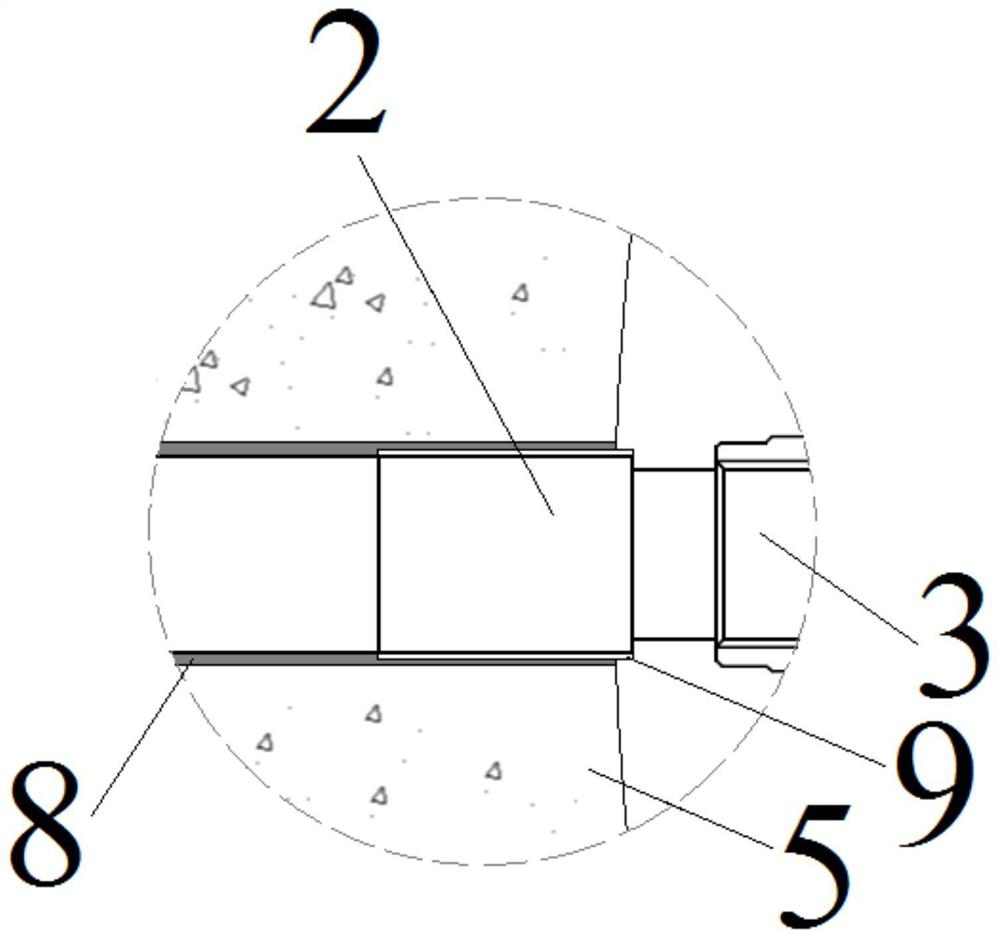

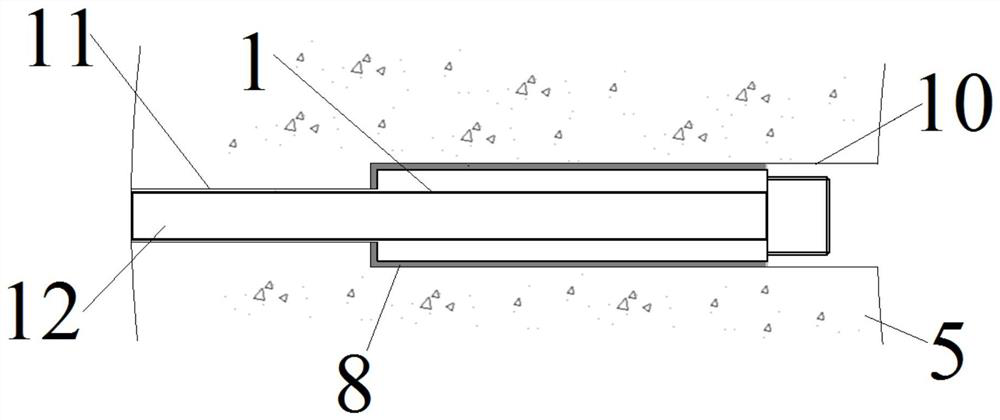

[0045] like figure 1 and figure 2 , open a blind hole 10 on the segment 5, the depth of the blind hole 10 is 21mm, the aperture is 37mm, inject the planting glue 8 into the blind hole 10 and insert the grouting pipe, one end of the grouting pipe is exposed on the outside of the segment 5 and A ball valve 3 is connected. The grouting pipe includes an upper sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com