A Method of Reducing the Unbalance of Screw Rotor by Stretching and Thickening

A rotor unbalanced, rotor technology, applied in rotary piston/swing piston pump components, rotary piston pumps, rotary piston machinery, etc., can solve the problems of screw rotor corrosion, incomplete exhaust, gas backflow, etc. , to achieve the effect of improving the ultimate vacuum, reducing the unbalance, and smoothing the suction and exhaust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

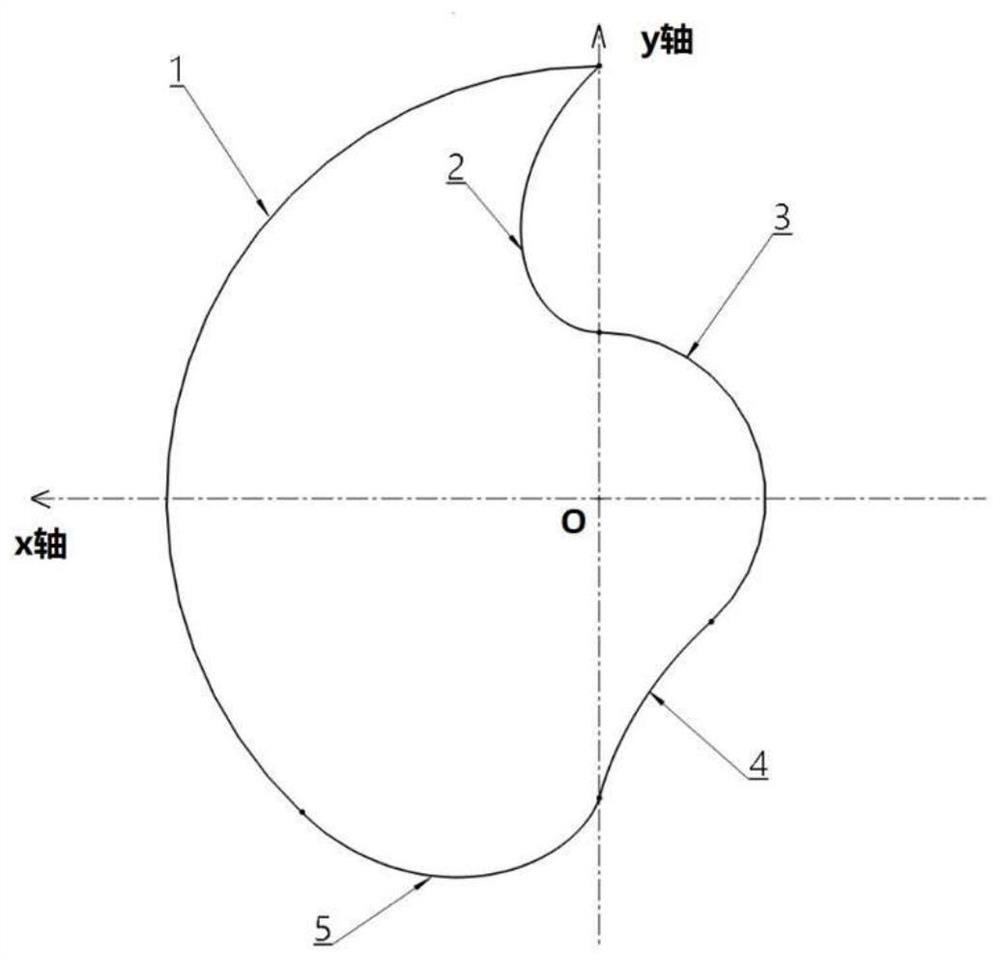

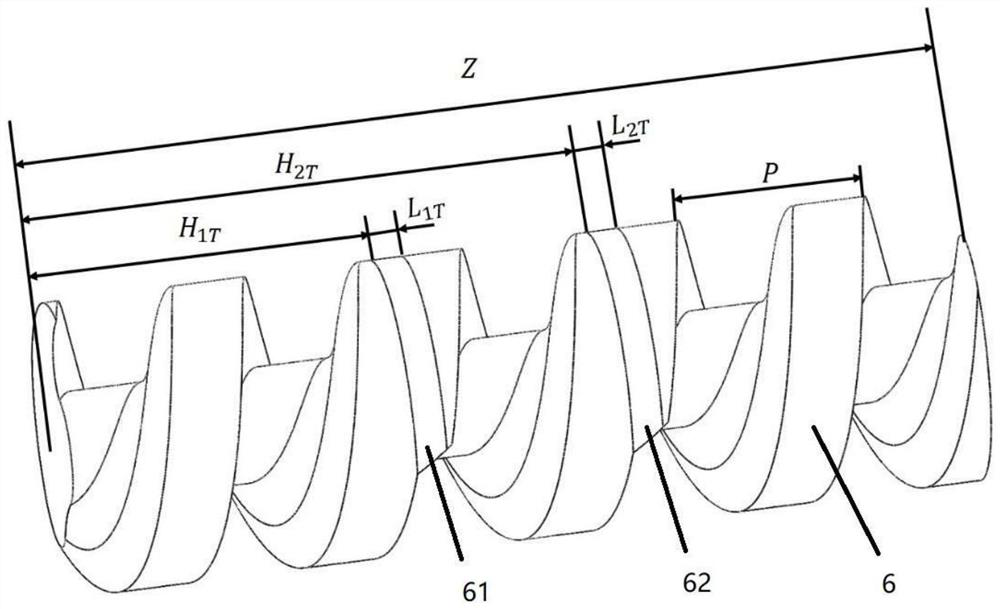

[0054] A method of reducing the unbalance of equal-pitch screw rotors by stretching and thickening. The end surface profile of the rotor body 6 is as follows: figure 1 As shown, it is composed of addendum circle 1, long epicycloid 2, dedendum circle 3, Archimedes spiral 4, and Archimedes spiral conjugate line 5, which is an asymmetric curve. The parameters of the screw rotor are as follows: addendum circle radius R t =78mm, root circle radius R f =30mm, the number of rotor leads m=4.5, the rotor lead is P=100mm, the total length of the rotor profile part Z=P×m=450mm, the steps are as follows:

[0055] Step 1: In figure 1 In the coordinates shown, the cross-sectional area A of the rotor end profile line 0 =0.01027034m 2 , the inertia tensor of the rotor is read out by Solidworks software as I xz =-1296181g·mm 2 , I yz =-14523069g·mm 2 , the eccentric angle of the rotor inertia tensor is calculated as

[0056]

[0057] The centroid coordinates (x 0 ,y 0 ) for x 0 ...

Embodiment 2

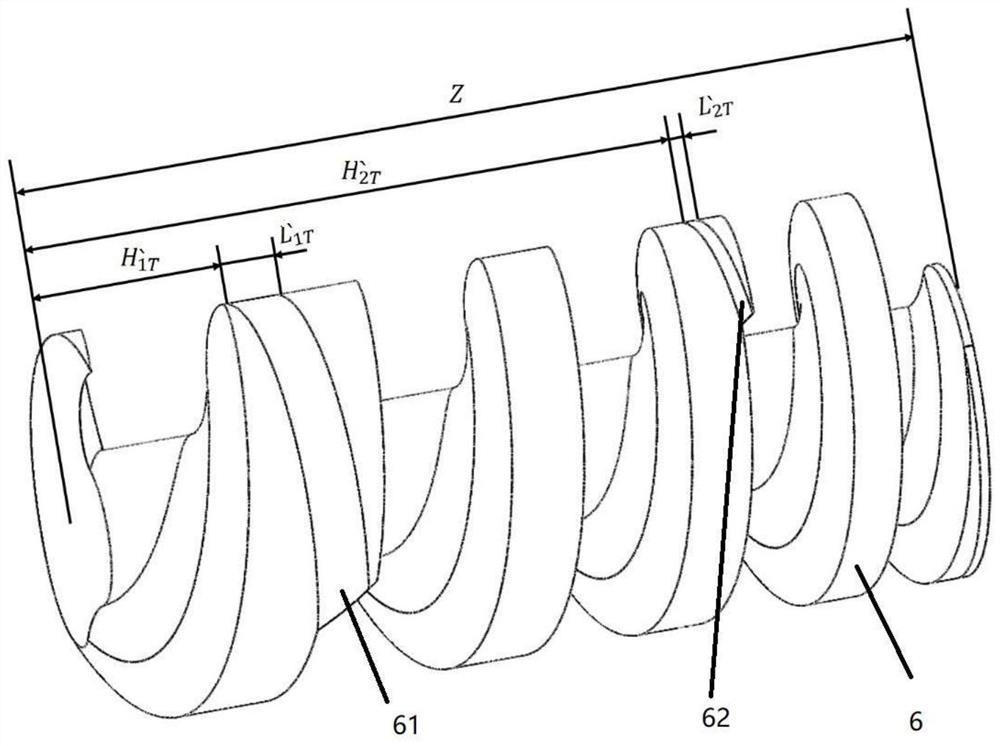

[0071] A method for reducing the unbalance of a gradually variable-pitch screw rotor by stretching and thickening. The end surface profile of the rotor body 6 is as follows: figure 1 As shown, it is composed of addendum circle 1, dedendum circle 3, long epicycloid 2, Archimedes spiral 4, and conjugate line 5 of Archimedes spiral, which is an asymmetrical curve. The parameters of a certain type of screw rotor are as follows: Addendum circle radius R t =78mm, root circle radius R f = 30mm, the number of rotor leads m = 4.5, the exhaust end is extended by 3.8mm for the convenience of processing, the total length of the rotor profile part Z = 318.8mm, the rotor lead gradually changes from 100mm to 40mm. Adopt the dynamic balance design method of the variable pitch rotor of the present invention, the steps are as follows:

[0072] Step 1: In figure 1 In the coordinates shown, the cross-sectional area A of the rotor end profile line 0 =0.01027034m 2 , the inertia tensor of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com