Large-span line vibration monitoring device and monitoring method

A vibration monitoring and large-scale technology, applied in the direction of measuring devices, measuring device casings, measuring instrument components, etc., can solve the problems of inability to monitor synchronously, lack of pneumatic synchronous monitoring devices, etc., and achieve the effect of simultaneous synchronous measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

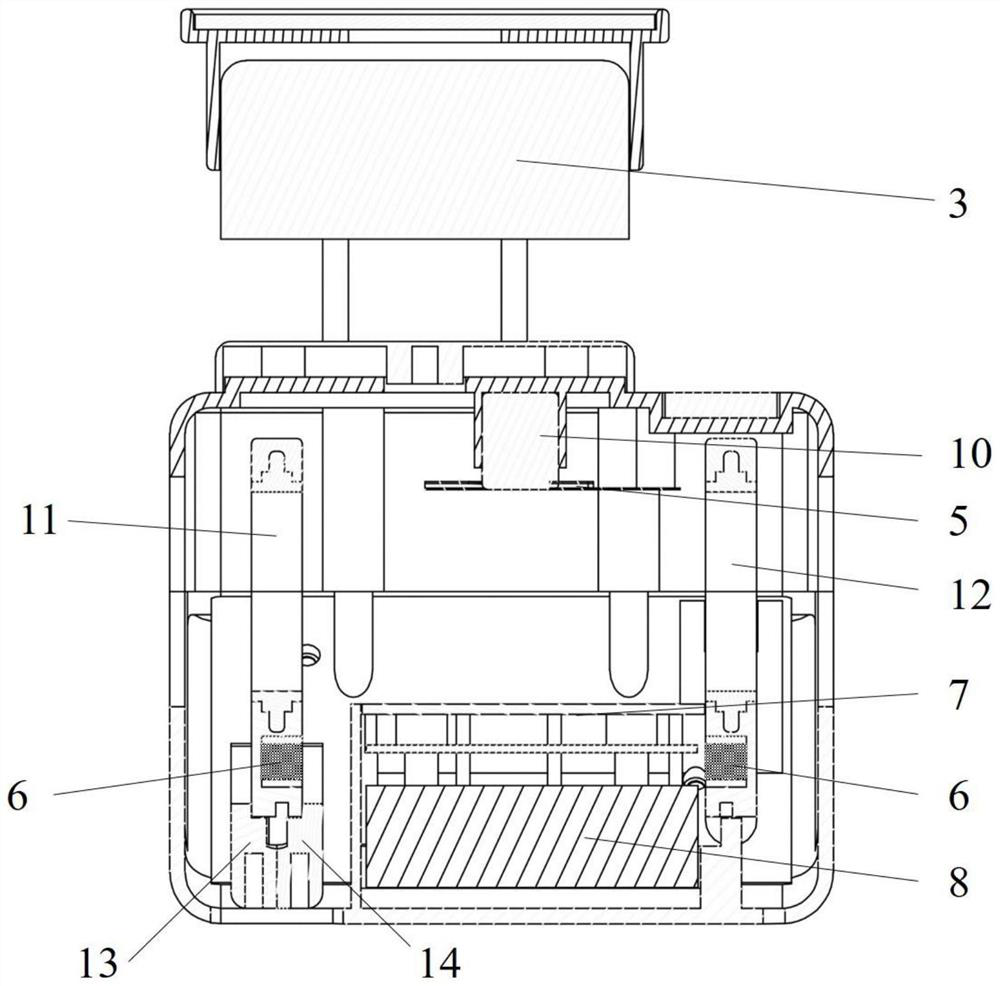

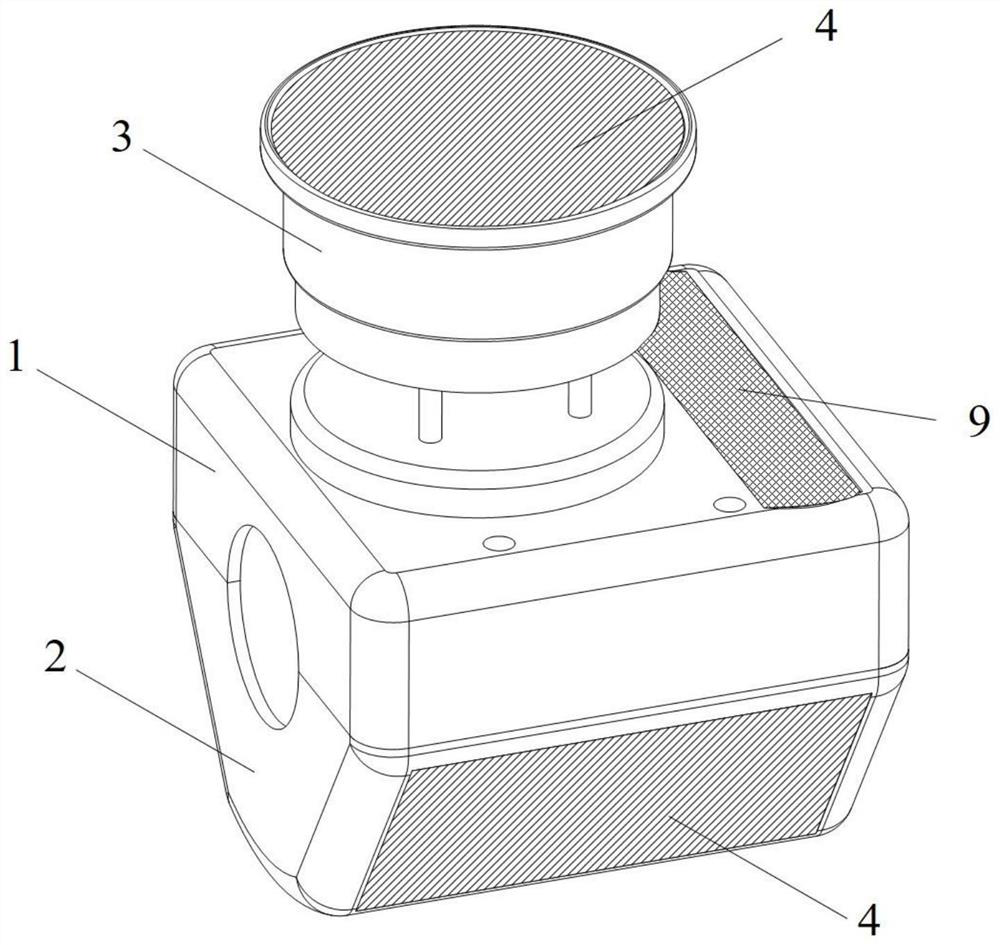

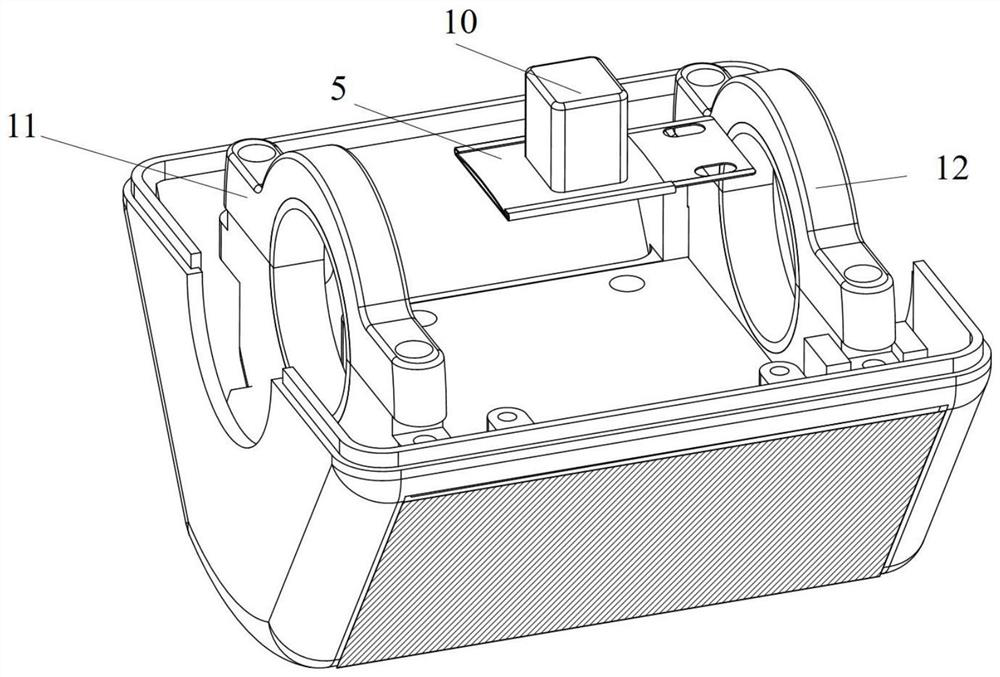

[0060] The invention provides a vibration monitoring device for a large-span line, such as figure 1 As shown, it includes: an ultrasonic wind speed and direction sensor 3, a hollow housing, a temperature sensor 5 arranged in the housing, a plurality of accelerometers 6 and a main control circuit board 7;

[0061] The housing is fixed on a UHV or large span wire; the ultrasonic wind speed and direction sensor 3 is installed above the housing;

[0062] The ultrasonic wind speed and direction sensor 3, the temperature sensor 5 and the accelerometer 6 are all connected to the main control circuit board 7;

[0063] The main control circuit board 7 is connected to a remote server;

[0064] The main control circuit board 7 processes the wire temperature collected by the temperature sensor 5, the wind speed and direction collected by the ultrasonic wind speed and direction sensor 3, and the wire vibration acceleration collected by the accelerometer 6 to obtain the wire aerodynamic force, vibra...

Embodiment 2

[0119] The invention provides a method for monitoring vibration of a large-span line, such as Figure 5 Shown, including:

[0120] Install the large-span line vibration monitoring device on the UHV or large-span line;

[0121] The temperature sensor 5 is used to measure the wire temperature, the ultrasonic wind speed and direction sensor 3 is used to measure the wind speed and direction, and the accelerometer 6 is used to measure the wire vibration acceleration; and the communication unit is used to send to the remote server.

[0122] Specifically, the temperature sensor 5 of the large-span line vibration monitoring device measures the wire temperature, the ultrasonic wind speed and direction sensor 3 of the large-span line vibration monitor device measures wind speed and direction, and the accelerometer 6 of the large-span line vibration monitor device measures the wire vibration acceleration;

[0123] The main control circuit board 7 of the large-span line vibration monitoring device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com