Drilling and piling device of highway guardrail breakdown van

A technology for piling devices and road guardrails, which is applied to road safety devices, supporting devices, drilling equipment and methods, etc., can solve the problems of inability to adjust the verticality of columns, cannot install columns at the same time, and the labor intensity of workers is high. Convenient and flexible, convenient and quick installation of drill pipe, saving assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

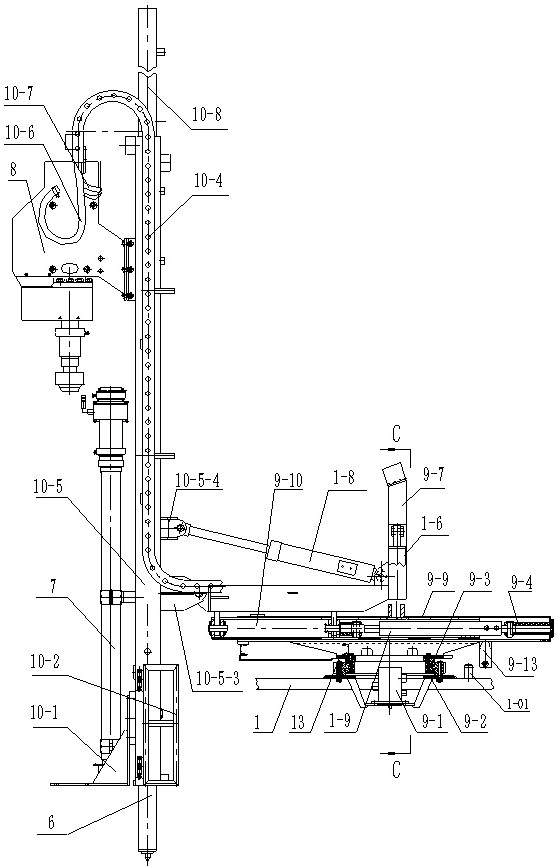

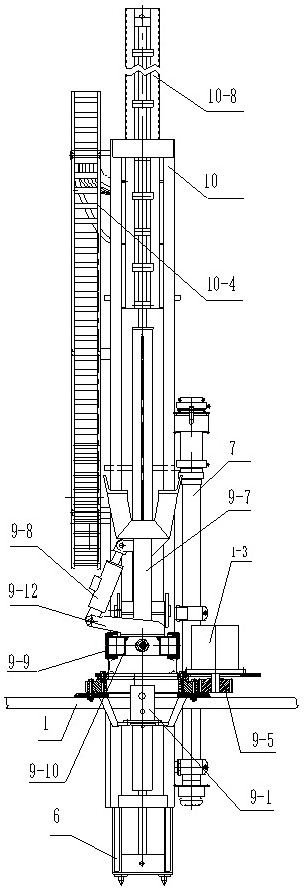

[0034] Embodiment 1: The drilling pile driver includes: a rotary assembly, a rotary platform, a drill pipe assembly 7, a hammer drill assembly 8, a slideway assembly 9 and a column assembly 10;

[0035] The slewing platform is installed on the slewing assembly, and the horizontal slideway assembly 9 is installed on the slewing platform; one end of the horizontal slideway assembly 9 is connected with a column assembly 10, and the hammer drill assembly 8 is installed on the column assembly 10, And slide on the column assembly 10; the drill pipe assembly 7 is connected to the side of the lower end of the column assembly 10.

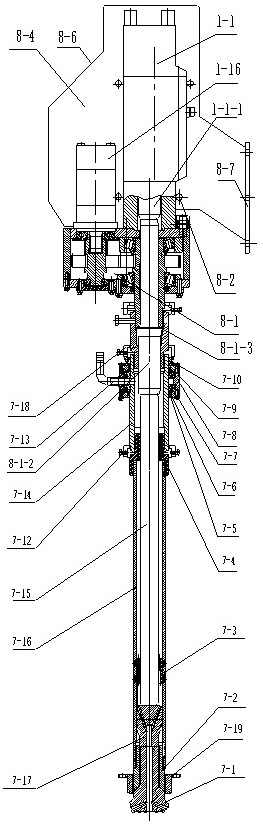

[0036] The drill pipe assembly 7 includes: drill bit 7-1, spline sleeve 7-2, air intake sleeve 7-3, drill pipe connecting sleeve 7-4, drill pipe lower end cover 7-5, drill pipe seal 7- 6. Drill pipe lower bearing 7-7, jacket 7-8, drill pipe upper end cover 7-9, drill pipe upper bearing 7-10, clamp 7-12, air intake pipe 7-13, inner sleeve 7-14, long drill Ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com