Ultrasonic detection 3D imaging analysis method

A technology of ultrasonic detection and analysis method, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis and material analysis using sound waves/ultrasonic waves/infrasonic waves, etc. Observe the distribution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically described below in conjunction with specific embodiments.

[0024] The ultrasonic detection 3D imaging analysis method in the present embodiment comprises the following steps:

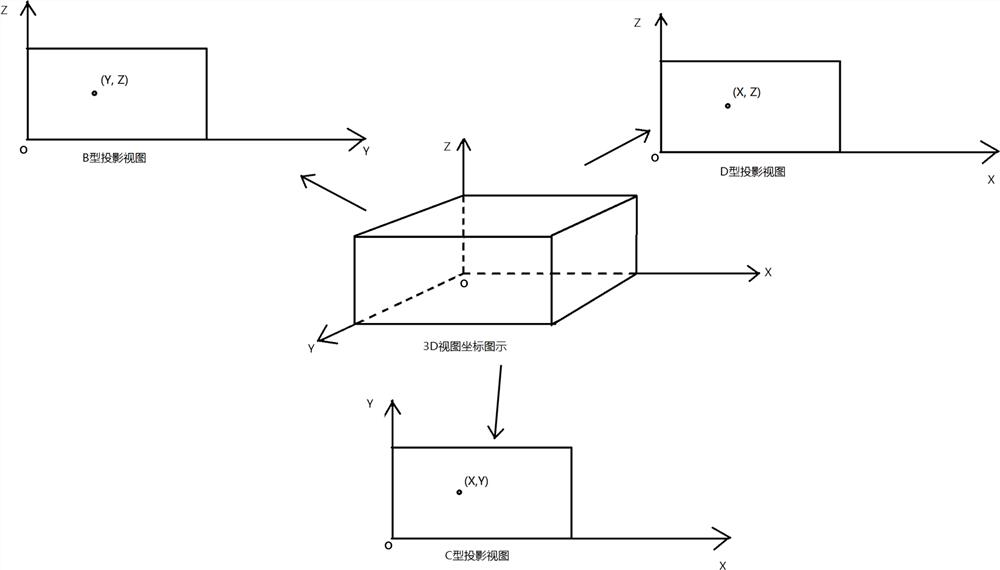

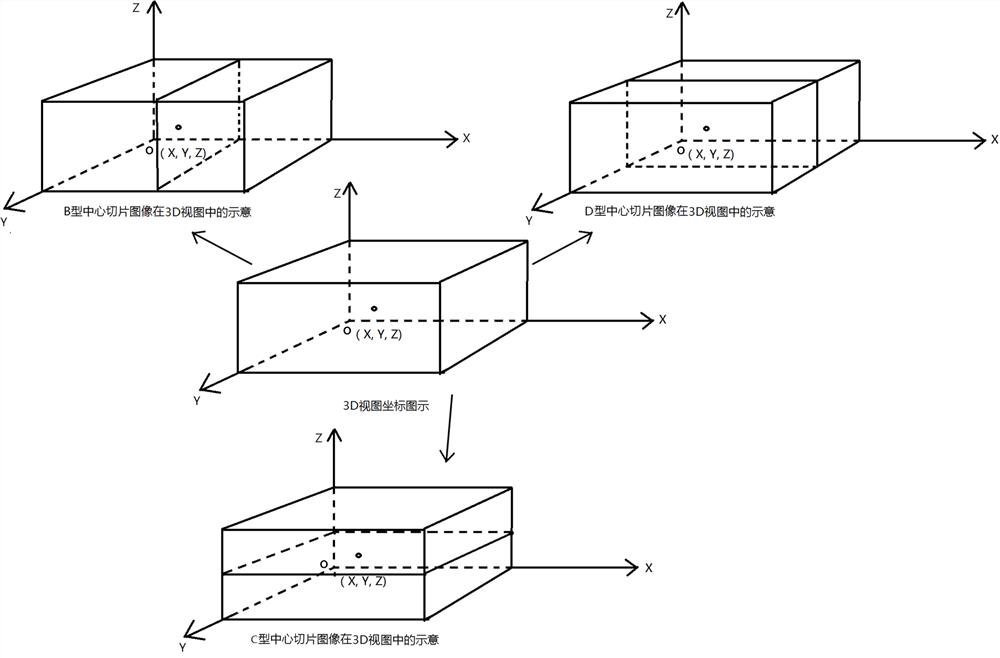

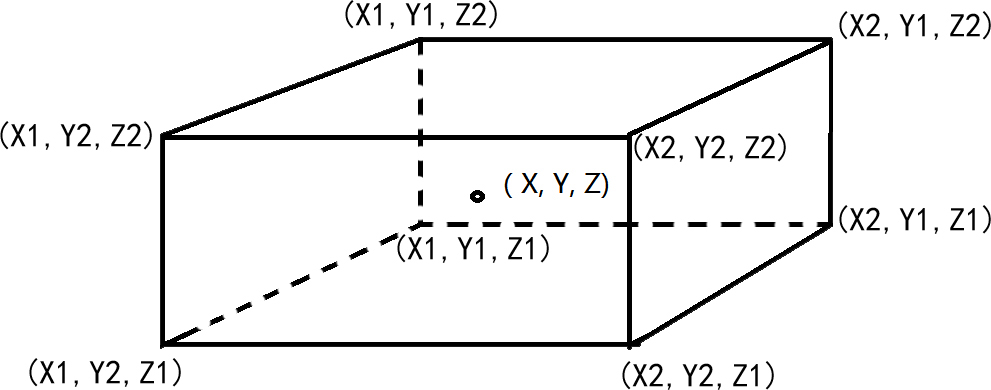

[0025] (1) if figure 1 As shown, the space Cartesian coordinate system O-XYZ is established, and the 3D view of the ultrasonic detection 3D imaging is projected according to the three-view method, and the B-type projection view is the plane YOZ, the C-type projection view is the plane XOY, and the D-type projection view is the plane XOZ;

[0026] (2) Set the cross cursor (X, Y, Z) used to measure the position in the B-type projection view, C-type projection view, and D-type projection view. The position value of the cross cursor in the B-type projection view is expressed as (Y , Z), the position value of the cross cursor in the C-type projection view is expressed as (X, Y), and the position value of the cross cursor in the D-type projection view is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com