A moving casing type multi-action water hydraulic radial piston pump

A multi-action, water-hydraulic technology, used in multi-cylinder pumps, variable-capacity pump components, components of pumping devices for elastic fluids, etc. Efficiency, difficult adjustment of gas spring pressure, etc., to achieve the effect of rapid reset, less leakage, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

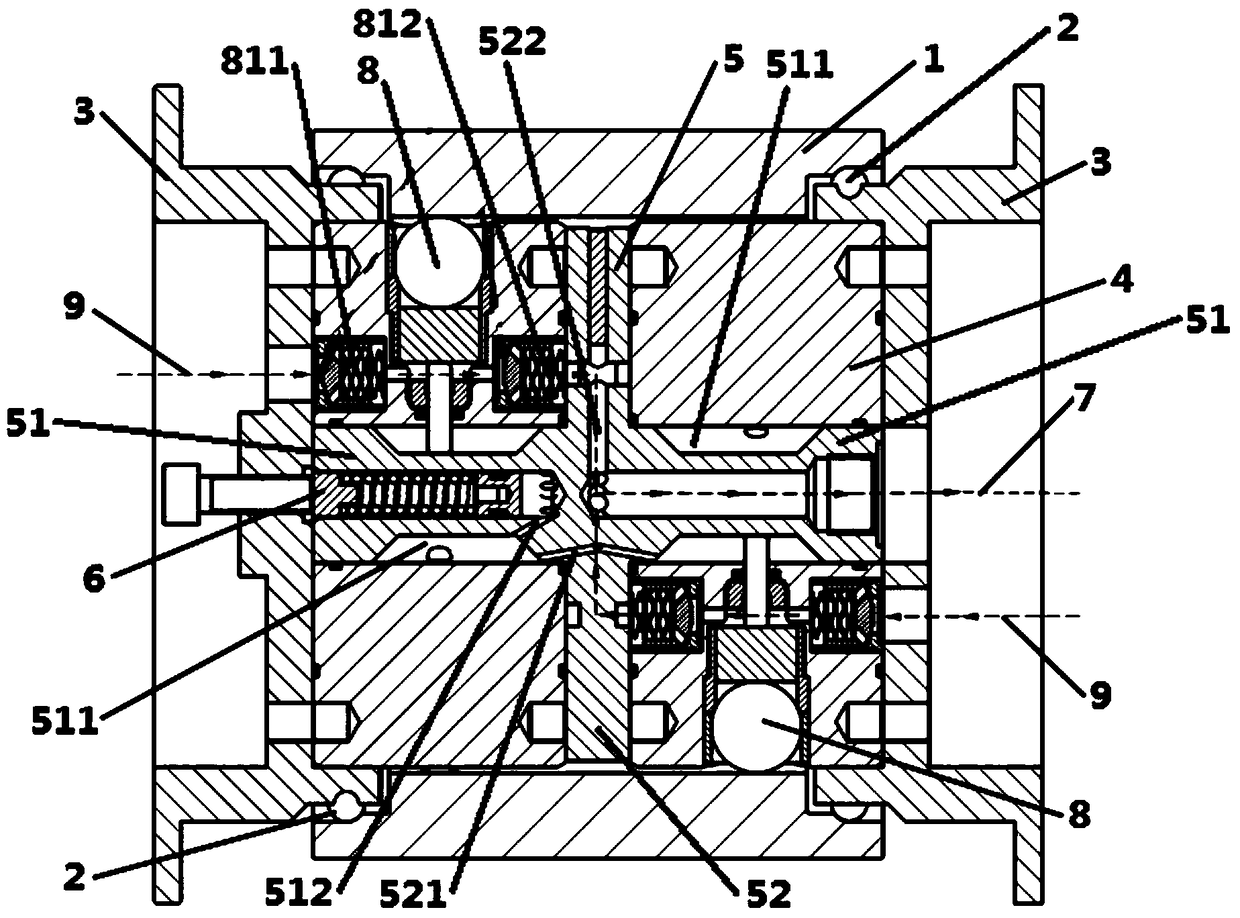

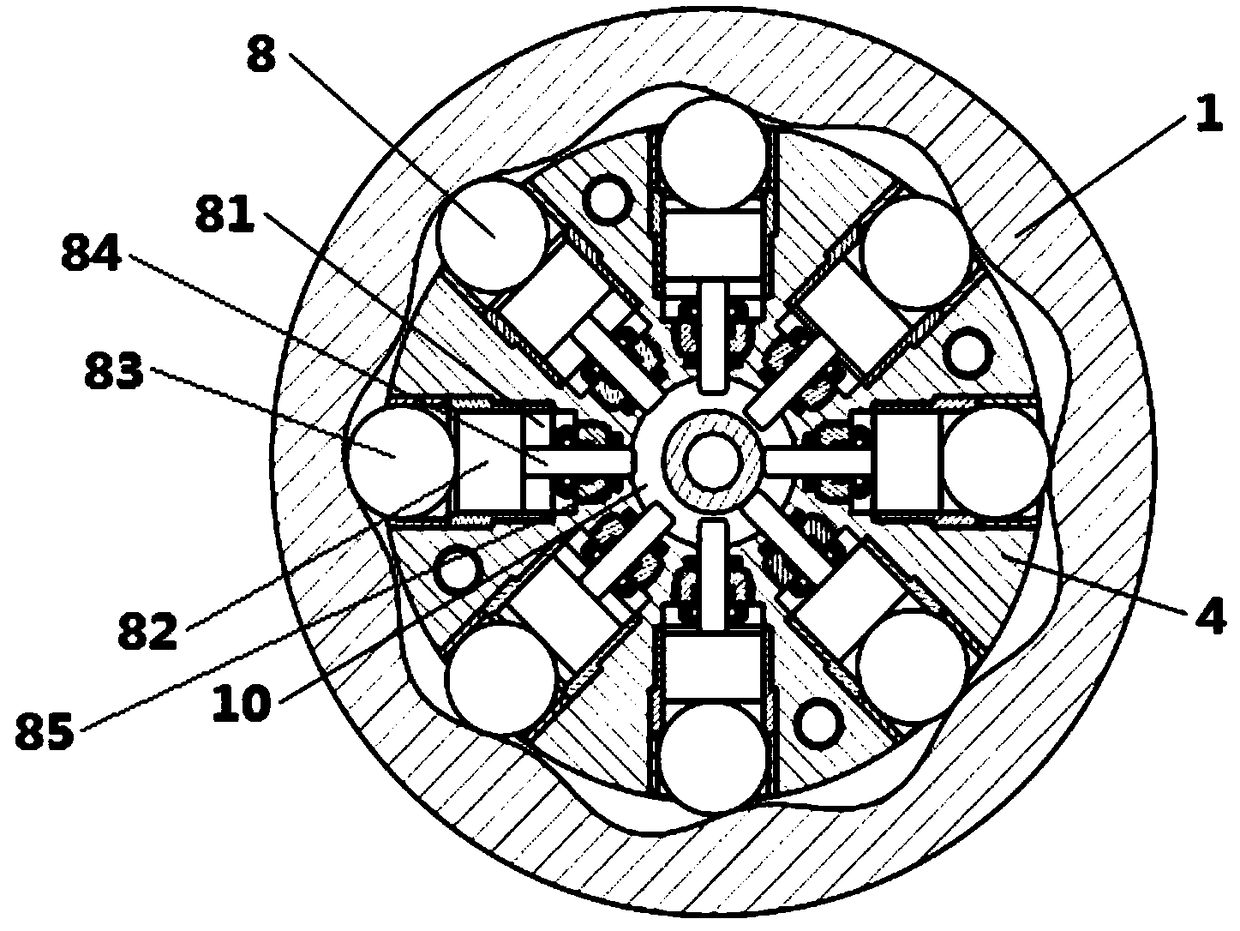

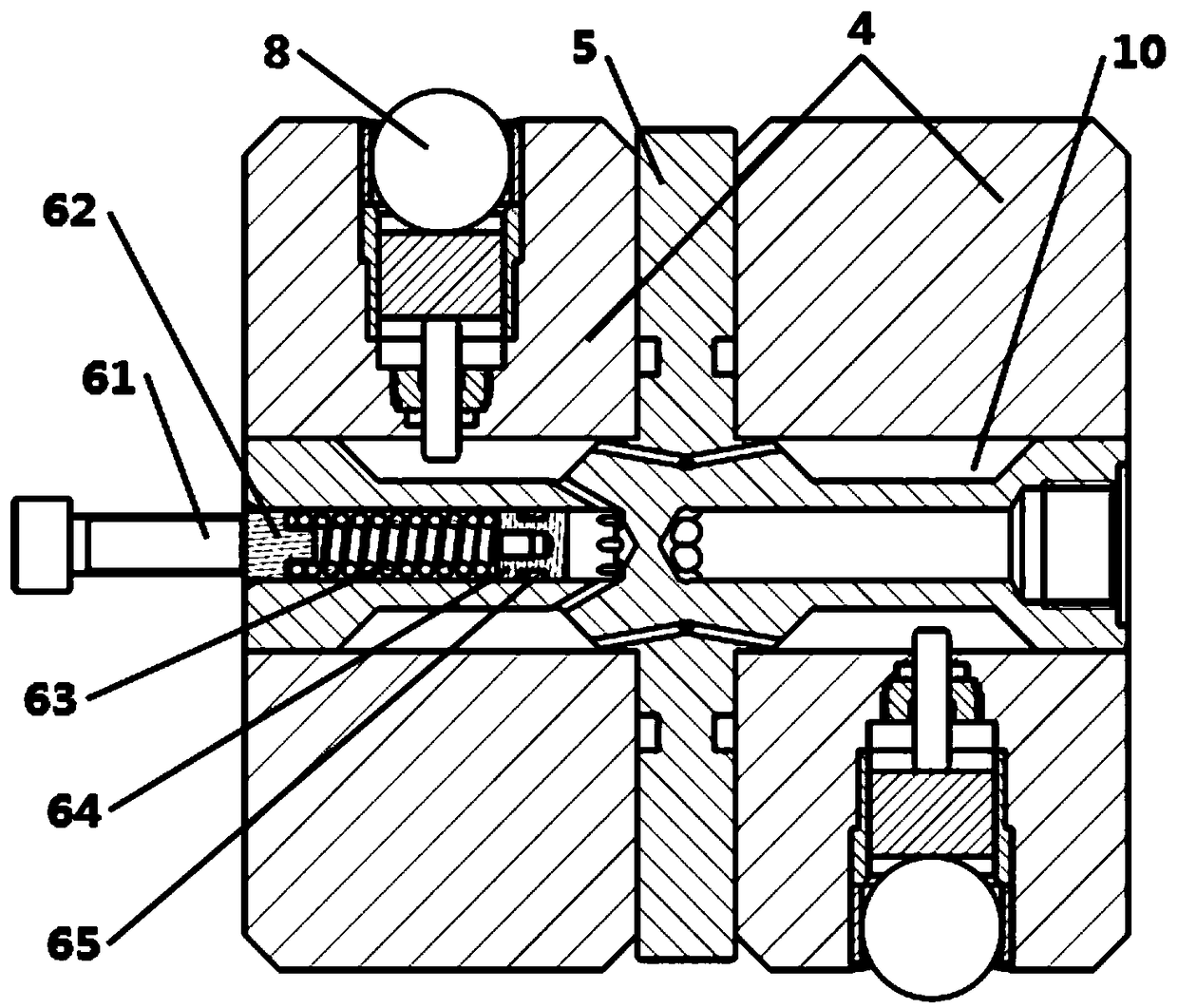

[0021] Example 1, such as Figure 1-4 As shown, this embodiment discloses a movable casing type multi-action water hydraulic radial piston pump, which includes a cylindrical casing 1, the radial section of the inner wall of the casing is a wave-shaped curve, and the two ends of the casing are respectively connected by rolling bearings 2 and one end. Cover 3 is connected, and cylinder block 4 is arranged in the shell, and the pipeline shaft 5 that disk shape and both ends all have columnar protrusion 51 is installed in the cylinder body, groove 511 is all set on the outer wall of columnar protrusion 51 at both ends, two The grooves are communicated through the channel 521 on the disc 52, and the inner cavity of the columnar protrusion at one end communicates with the groove on the outer wall of the columnar protrusion adjacent to the disc 512, and in addition, a Extend the pressure regulating device 6 out of the adjacent end cover, inject pressure liquid into the above groove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com