Automatic control system of cement bunker cleaning equipment

An automatic control system and cement storage technology, applied in the field of storage cleaning, can solve problems such as limited working space, harsh working environment, and large dust, so as to achieve maximum efficiency, save initial investment, and improve economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the accompanying drawings and examples, and the protection scope of the present invention cannot be limited by this. The purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

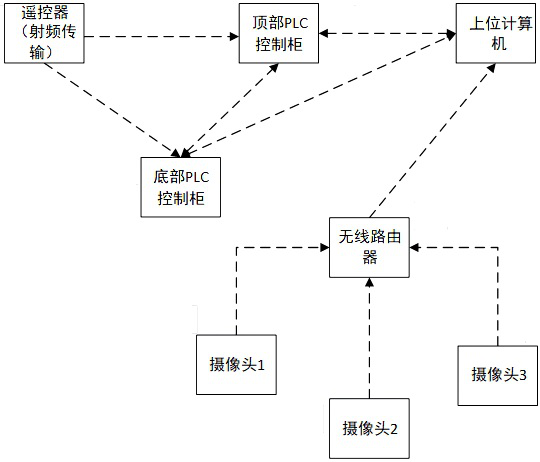

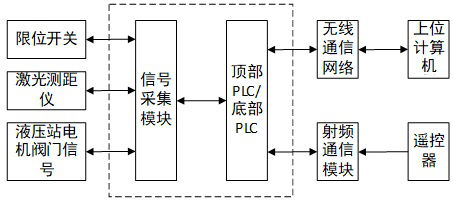

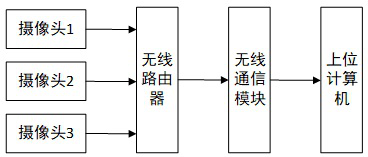

[0032] combined with Figure 1-4 , the automatic control system of a cement warehouse cleaning equipment according to the present invention, including a wireless communication module, a PLC system, a limit switch, a host computer, a camera system, a laser rangefinder, a remote controller and a cable reel;

[0033] The wireless communication module includes the wireless transceiver module of the PLC system, the wireless router and the wireless transceiver module of the upper computer; the wireless transceiver module and the wireless router of the PLC system communicate with the upper computer using the S7 communication protocol and transmit data;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com