Sound absorption device

A sound-absorbing device and chamber technology, applied in the field of noise reduction, can solve the problems of small space, complex mechanical equipment structure, increased thickness, etc., and achieve the effects of sound absorption, improving the frequency range of sound absorption, and saving space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

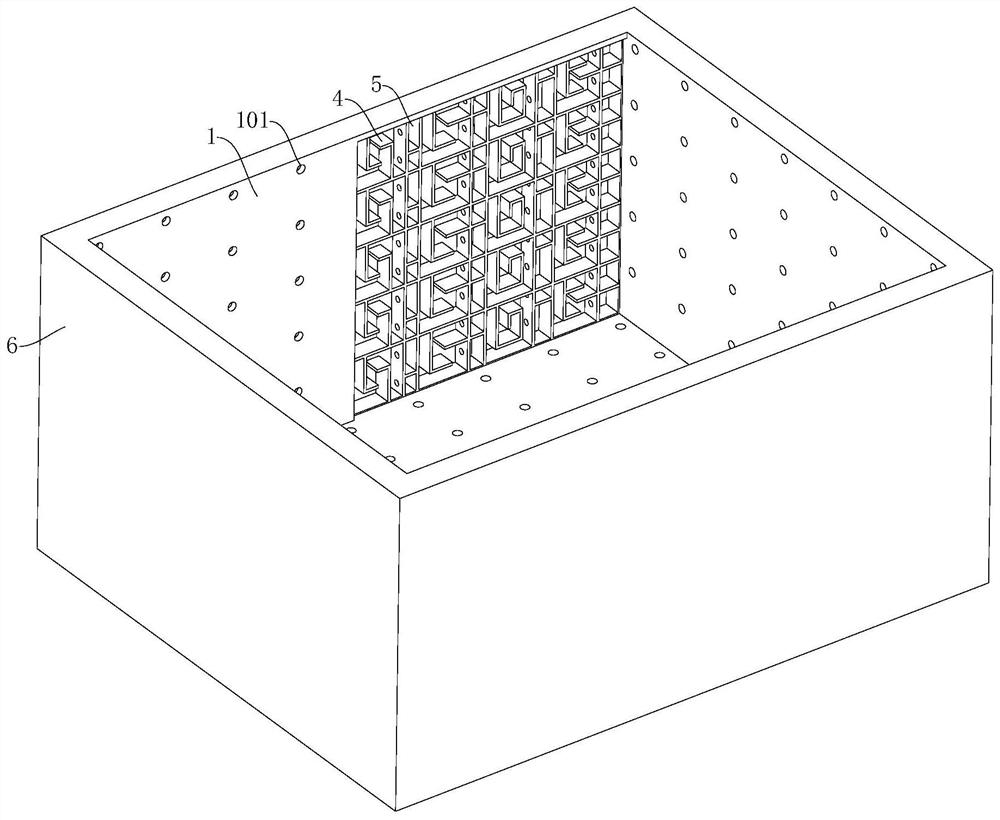

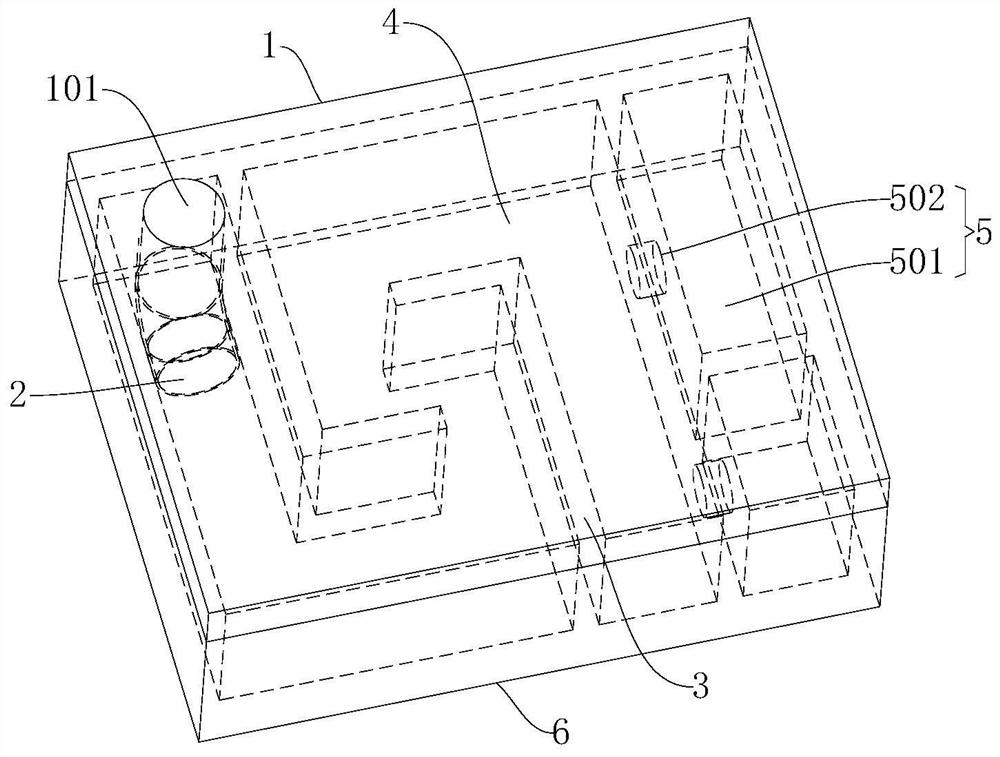

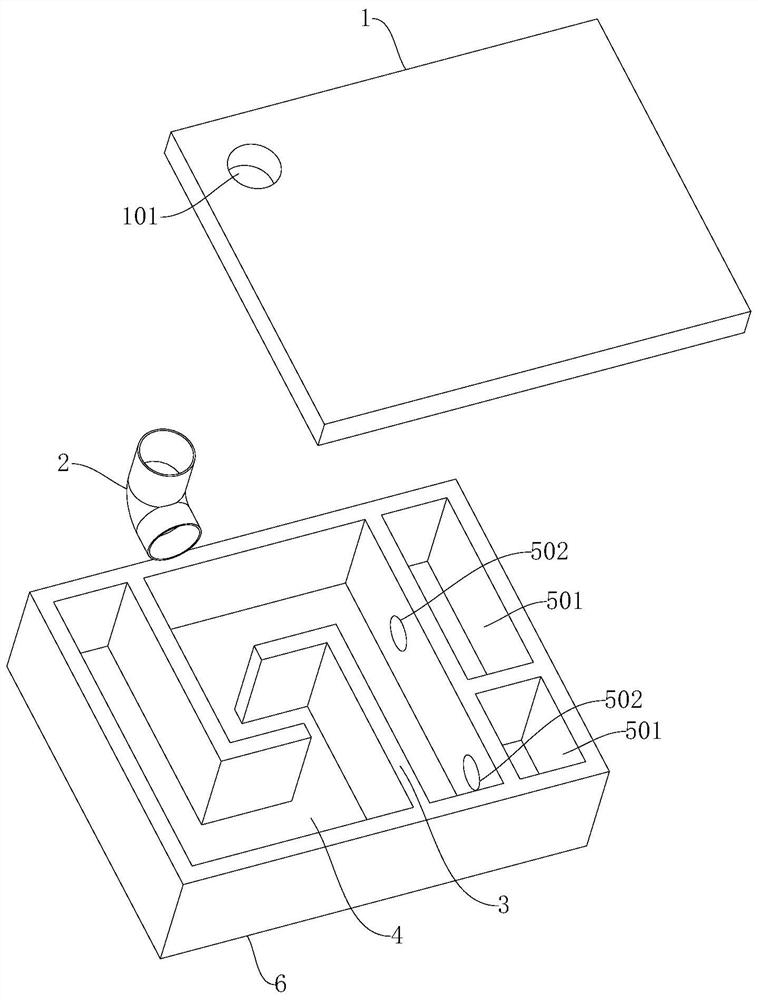

[0027] Such as figure 1 As shown, the sound absorbing device of this embodiment is used to absorb low-frequency noise generated by mechanical equipment. The specific structure includes an inner panel 1, an outer panel 6 and a partition 3; chamber; wherein the partition plate 3 is located in the chamber, and is used to divide the chamber into a plurality of labyrinth chambers 4, and the plurality of labyrinth chambers 4 are regularly distributed in the chamber; the inner plate 1 is provided with a plurality of first passages Holes 101, each first through hole 101 communicates with each labyrinth chamber 4 in one-to-one correspondence, and the connection between each first through hole 101 and the labyrinth chamber 4 is located at the starting point of the corresponding labyrinth chamber 4, the first A through hole 101 is used to guide the sound...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap