Capacitor film production tape splicing device capable of improving utilization rate

A utilization rate and capacitance technology, applied in the direction of capacitors, capacitor manufacturing, circuits, etc., can solve problems such as low efficiency, delaying the production process of the assembly line, etc., and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

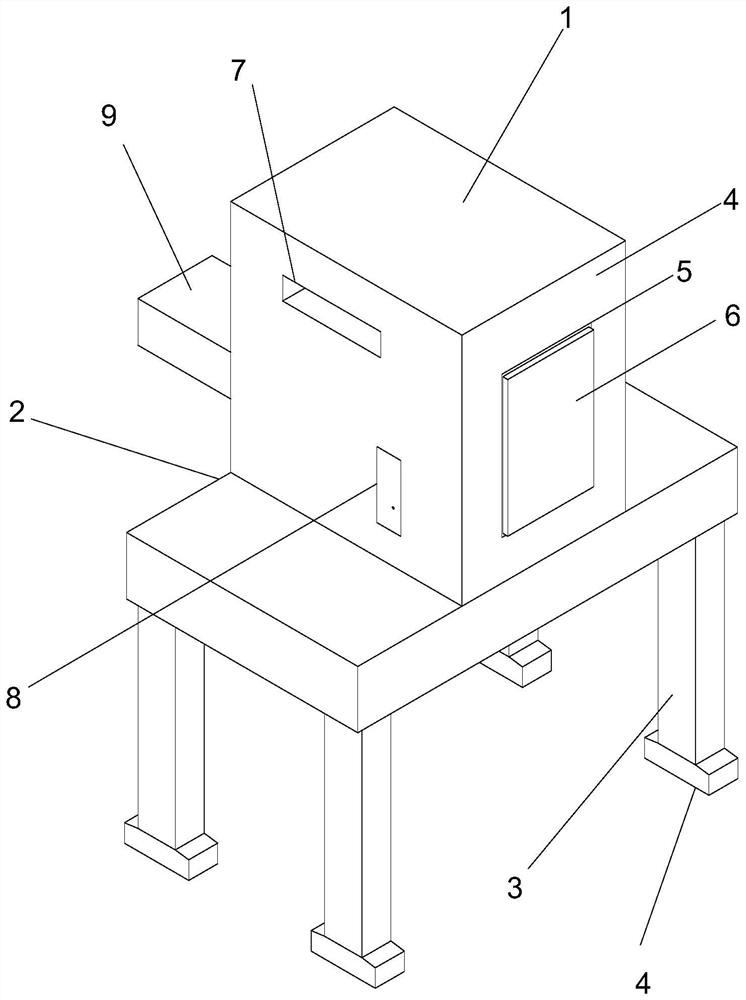

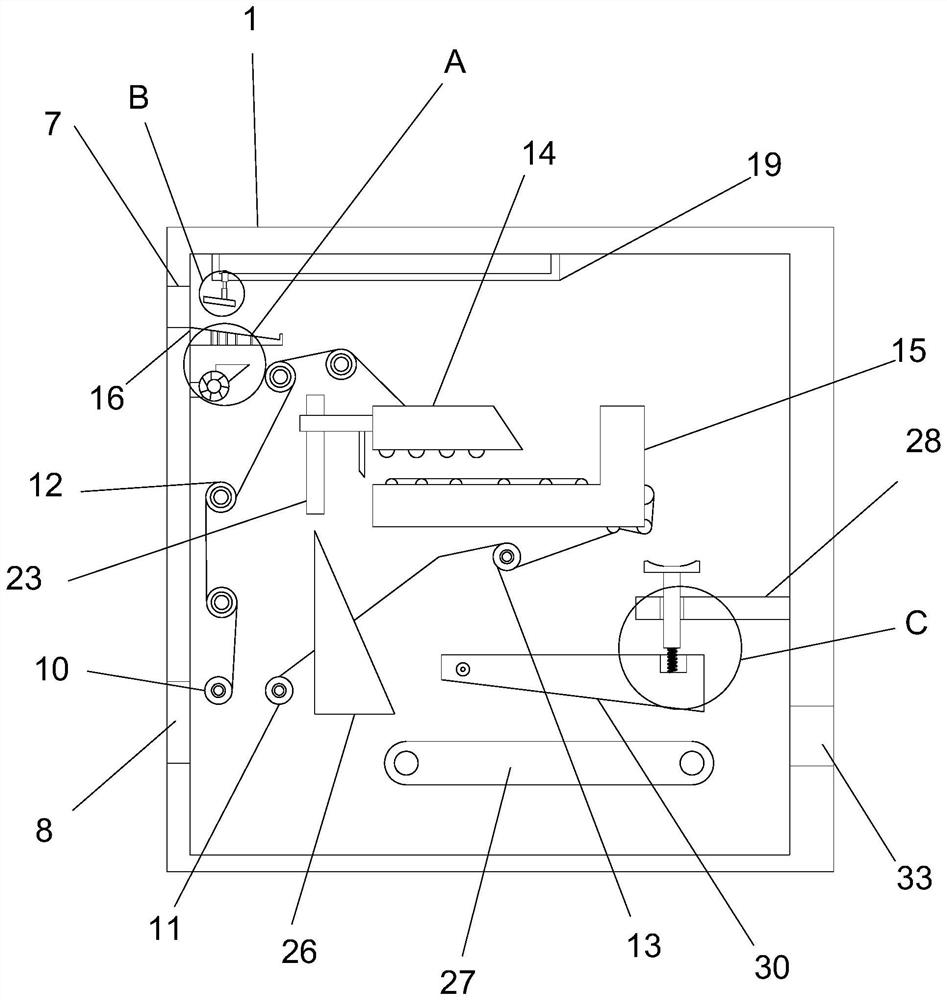

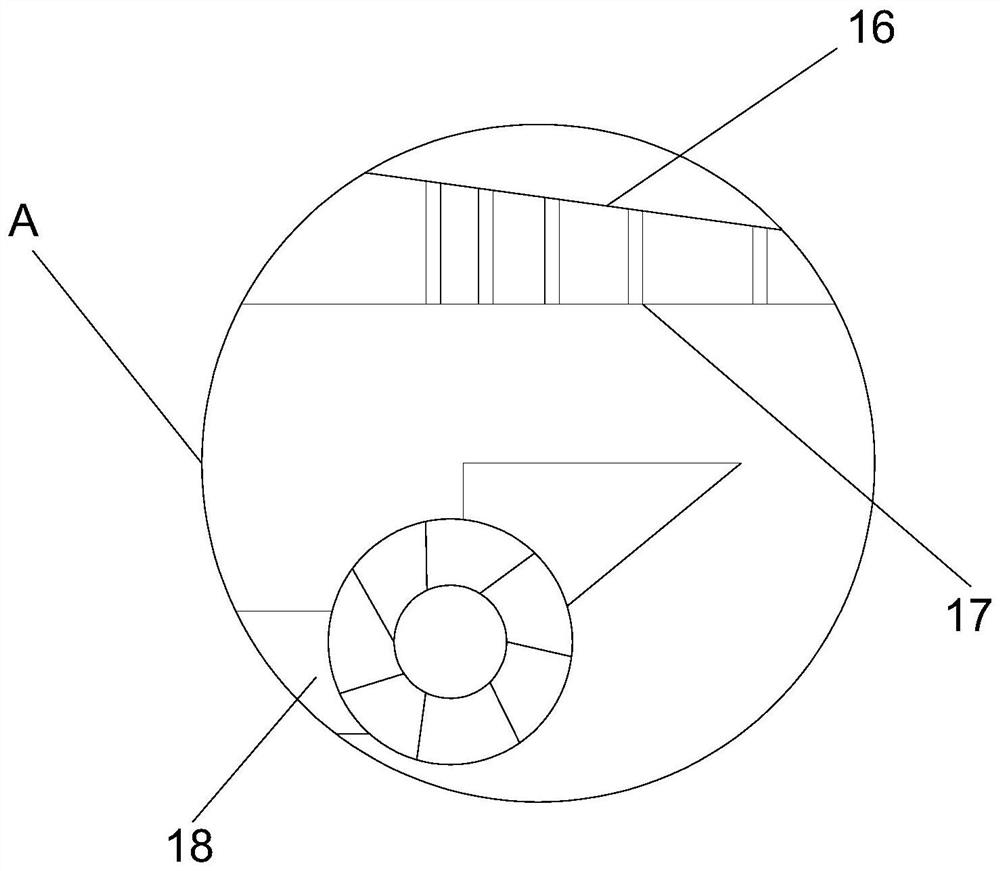

[0025] Embodiment: a kind of capacitive film that improves utilization rate is used to produce splicing device, as Figure 1-Figure 6 As shown, the splicing box 1 is included, the splicing box 1 is a rectangular structure, and the interior of the splicing box 1 is hollow, and a processing table 2 is arranged below the splicing box 1, and the processing table 2 is a rectangular plate. The bottom is provided with a support column 3, the support column 3 is a rectangular hollow metal rod, and the number of the support column 3 is four, and the four support columns 3 are fixed on the corners around the bottom surface of the processing table 2, and the bottom surface of the support column 3 is set There is a stabilizing pad 4, the stabilizing pad 4 is a trapezoidal rubber block, and the bottom surface of the stabilizing pad 4 is provided with a friction-resistant stripe groove, and the upper wall of the stabilizing pad 4 is fixedly connected with the lower wall of the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com