Processing method of sewable LED lamp string

A technology of LED light strings and processing methods, which is applied in the field of lighting, can solve the problems of low yield rate of thin light strings, etc., and achieve the effect of increasing product appearance, improving product yield rate, and strengthening wire strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

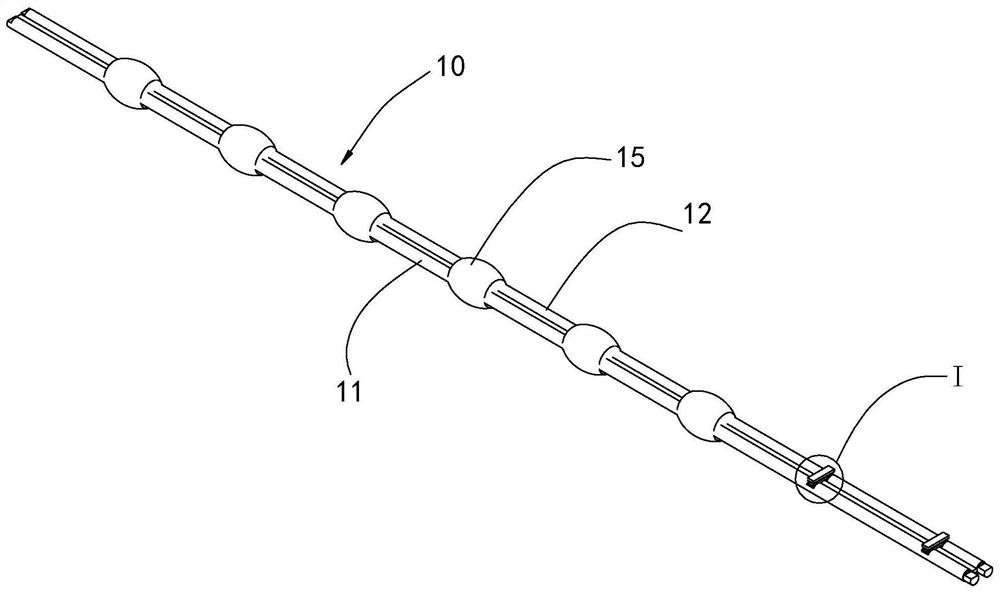

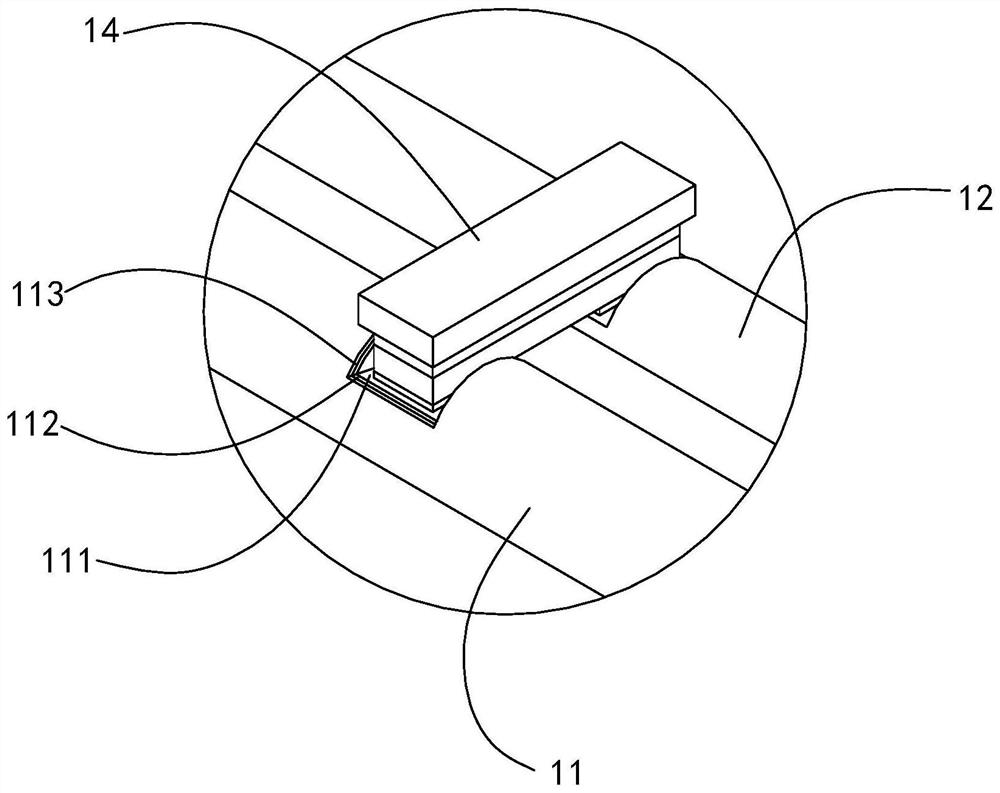

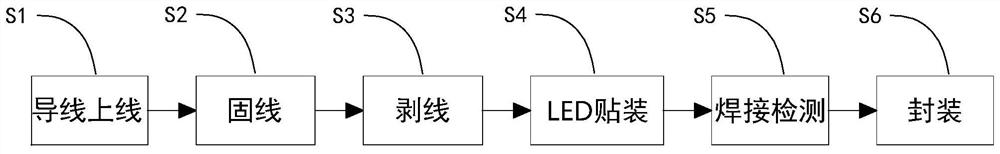

[0042] Such as figure 1 , 2 As shown, the sewable LED lamp string 10 in the embodiment of the present invention includes at least two wires, a number of flip-chip LEDs 14 and a number of encapsulants 15. In this embodiment, two wires are taken as an example for illustration. The two wires 11, 12 Arranged side by side, the diameters of the wires 11 and 12 are 0.03 mm to 0.25 mm. The wires 11 and 12 each include a wire core 111 , an insulating layer 112 covering the surface of the wire core 111 and a glue layer 113 covering the outside of the insulating layer 112 . The wires 11 and 12 in this embodiment are enameled wires. The glue layer 113 and insulating layer 112 of the wires 11 and 12 are removed at intervals ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com