A cable trench and its laying process

A technology of cable trenches and grooves, which is applied in the directions of cable laying equipment, cable installation, ground cable installation, etc., which can solve problems such as time-consuming and labor-intensive, affecting construction efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

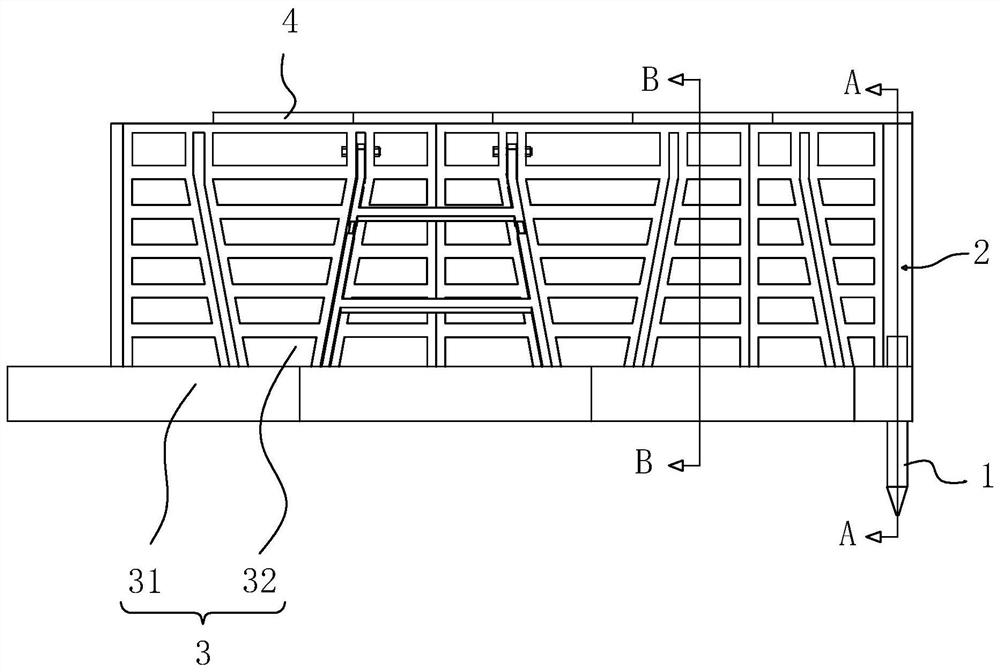

[0049] The following is attached Figure 1-8 The application is described in further detail.

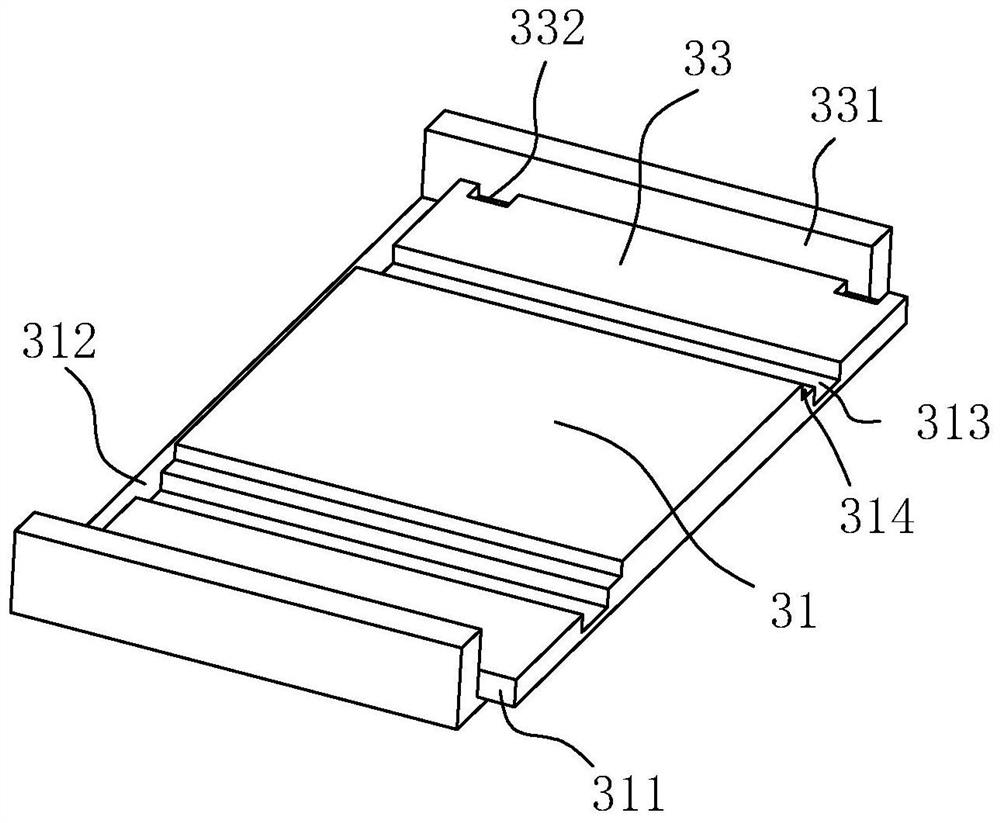

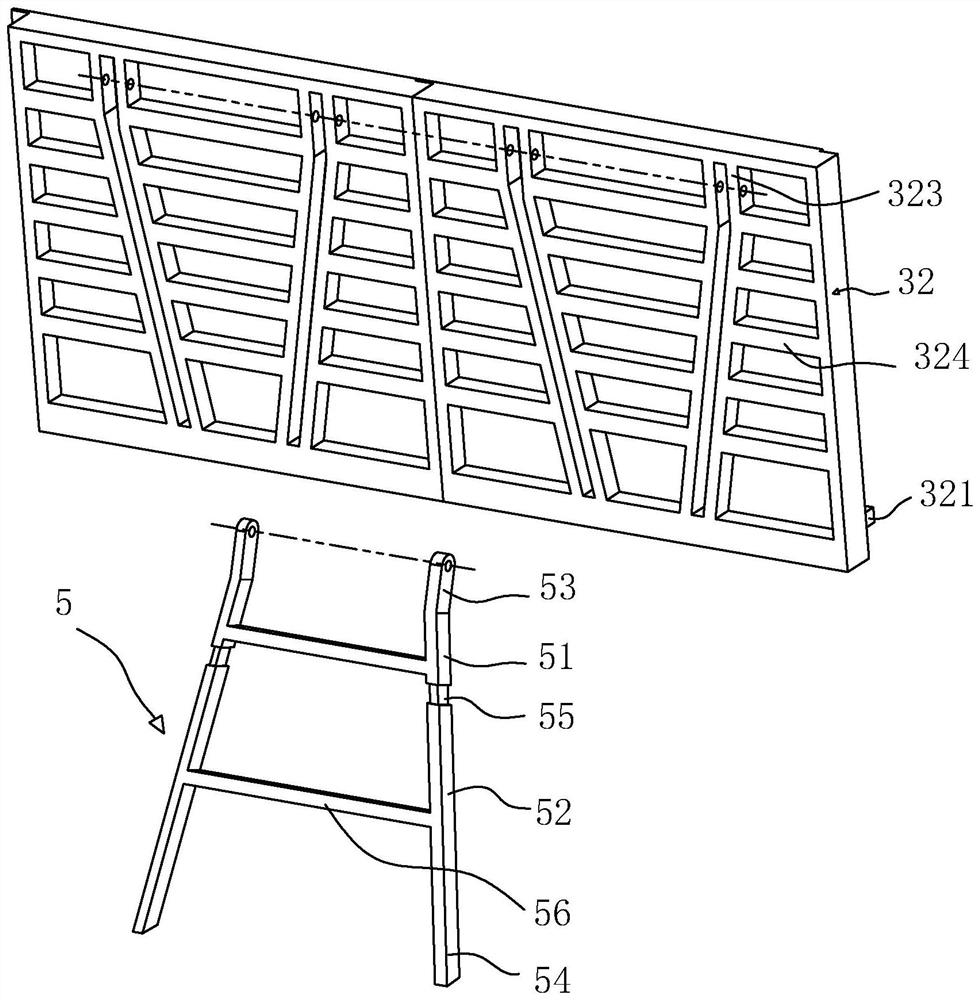

[0050] The embodiment of the present application discloses a cable trench, which includes a positioning rod 1, a positioning section 2 and a trench section 3; At the end of the ditch section 3, the longitudinal section of the positioning section 2 is the same as that of the ditch section 3; the ditch section 3 includes a first bottom plate 31 and a first side plate 32; the first side plate 32 has two, two first The side plates 32 are symmetrically assembled on both sides of the first bottom plate 31 ; the tops of the positioning section 2 and the groove section 3 are equipped with cover plates 4 .

[0051] The initial installation position of the cable trench is determined by the positioning rod 1, the installation efficiency of the positioning section 2 is improved, and the adjustment and positioning during the installation process of the positioning section 2 are reduced. And the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com