Automatic coil winding grass trimmer

A technology for automatic winding and weeding machines, which is applied to harvesters, agricultural machinery and implements, cutters, etc. It can solve the problem that the initial position of the upper end surface of the head shell cannot be well controlled, the manufacturing and assembly are inconvenient, and the position cannot be limited. Coordination and other issues to achieve the effect of increased threading pass probability, reduced vibration, and good concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

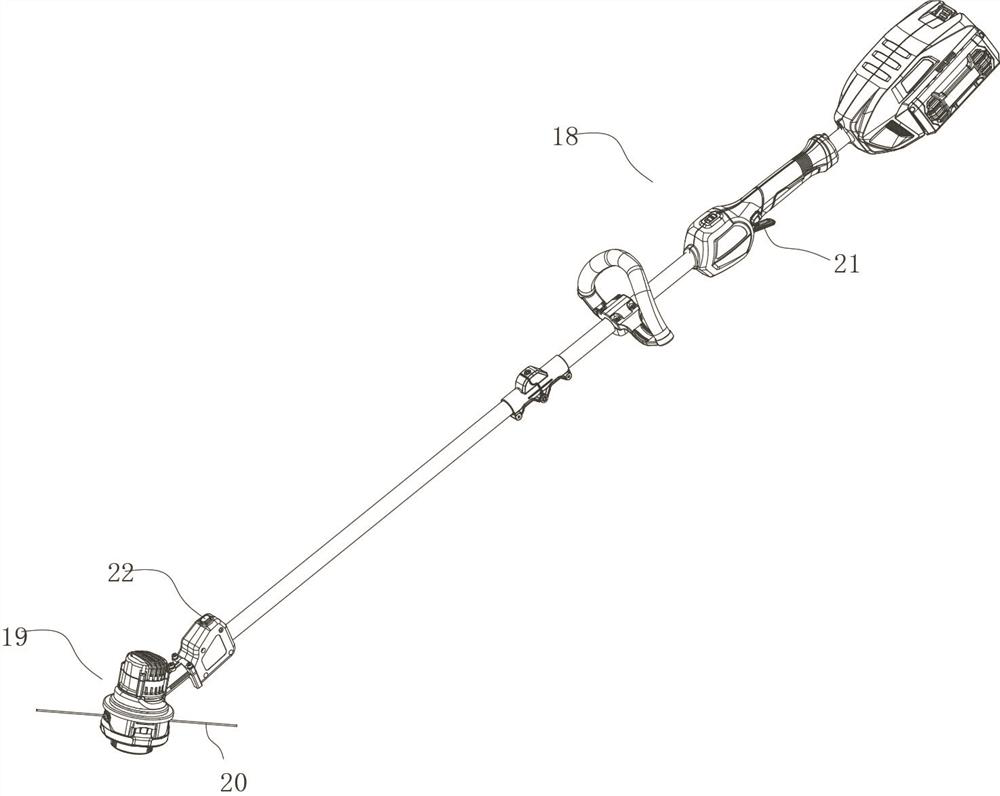

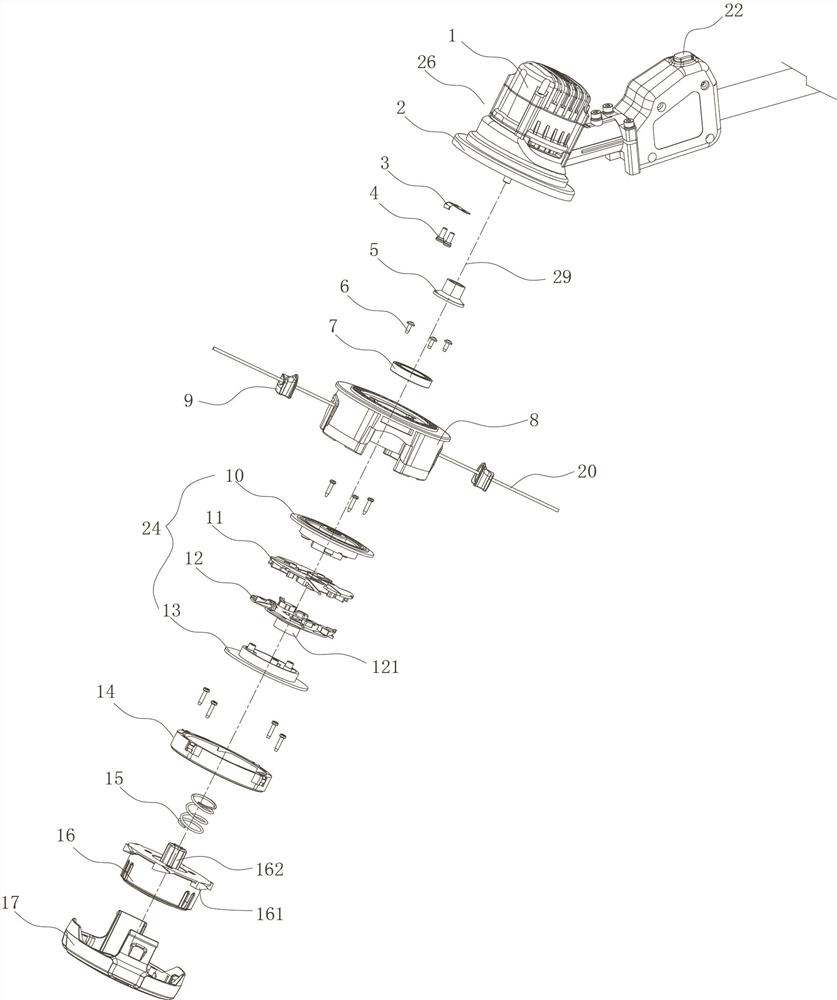

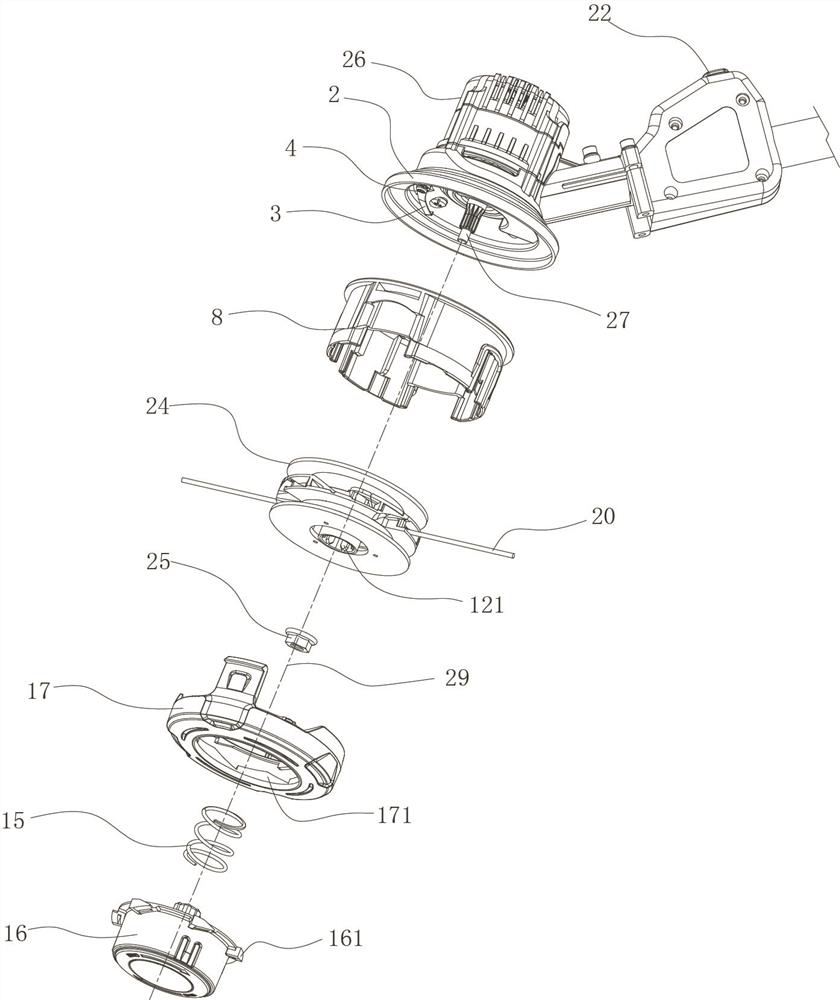

[0034] refer to Figure 1-7 Shown, be the specific embodiment of the present invention: a kind of automatic coiling mowing machine 18, comprises: mowing head 19; Motor 1, is used to drive described mowing head 19 to rotate with a center shaft 29; The switch is a switch trigger 21 arranged in the middle of the connecting rod of the mower, which is used to control the motor 1 to rotate at the first speed and in the first direction; the second switch is a button arranged at the lower end of the connecting rod of the mower The switch 22 is used to control the motor 1 to rotate at a second speed and a second direction; wherein, the starting priority of the second switch is higher than that of the first switch, that is, when the second switch is in the open state When the switch trigger 21 is pressed intentionally or unintentionally, the switch trigger 21 cannot control the working state of the motor 1; wherein, the second speed is much lower than the first speed;

[0035] Wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com