Spraying dust-falling structure for mobile dust remover

A technology for spray dust reduction and dust collector, which is applied in the direction of using liquid separating agents, chemical instruments and methods, combined devices, etc., can solve the problems of waste of water resources, single structure of spray dust reduction, difficult reuse of water, etc., and achieves rapid settlement efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

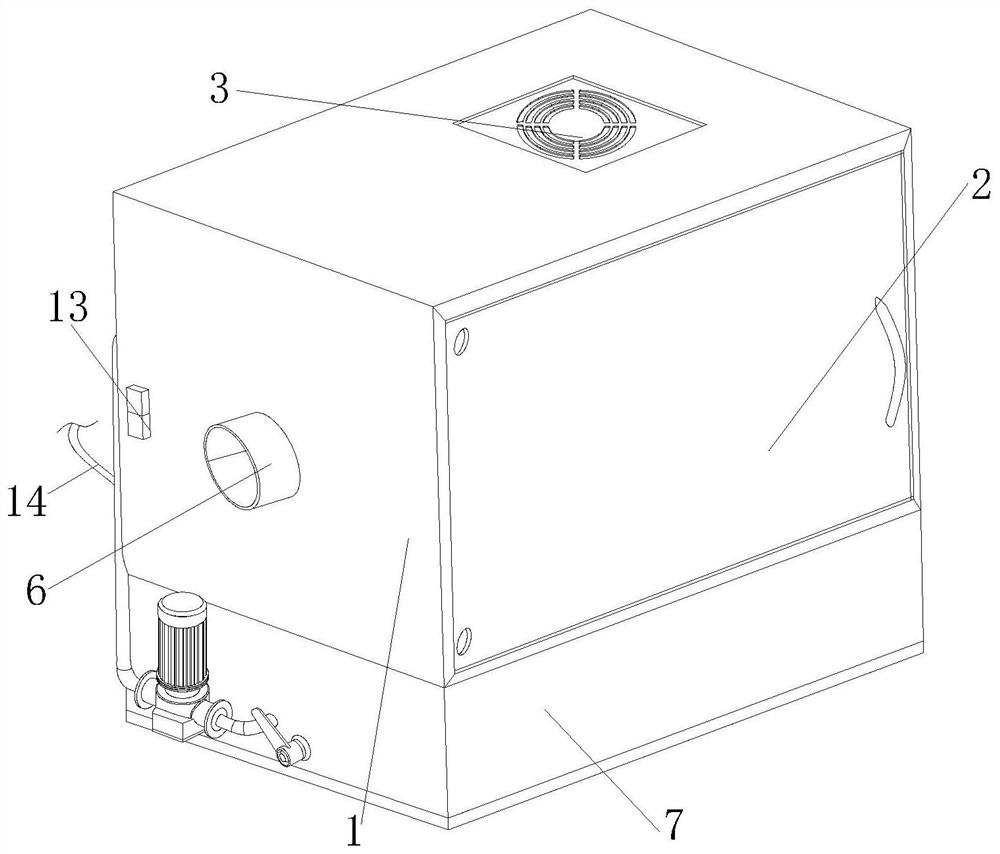

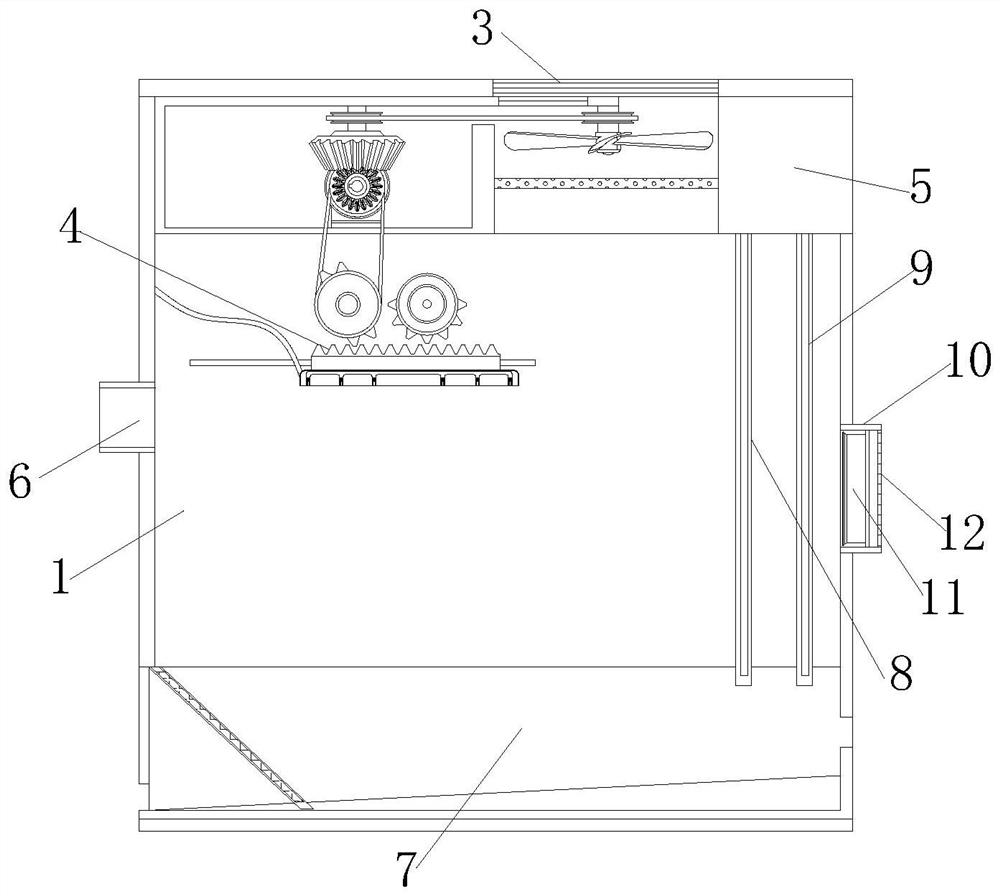

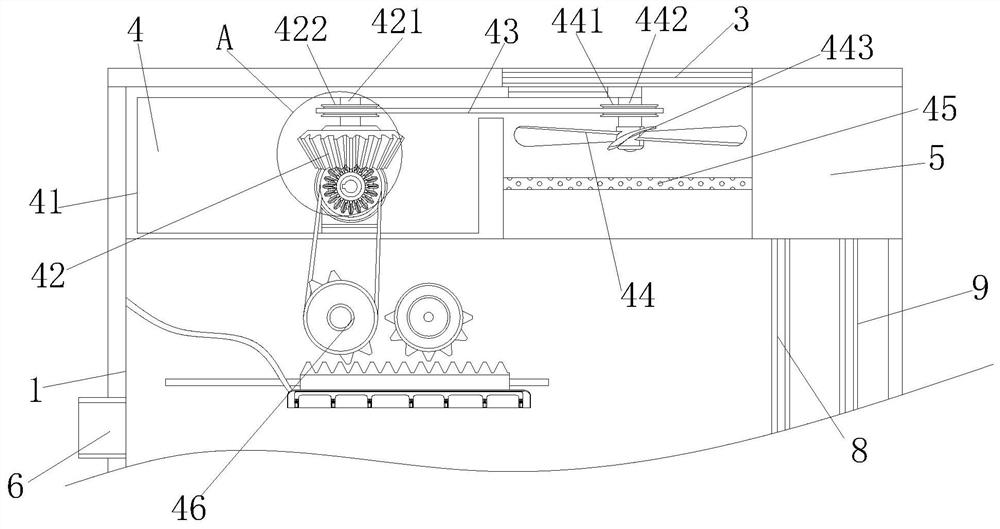

[0030] see figure 1 with figure 2 , a spray dust suppression structure for a mobile dust collector of the present invention, comprising a box body 1, an inspection door 2, a ventilation window 3, a processing mechanism 4, a mounting seat 5, an air intake cylinder 6, a water filter mechanism 7, a first filter screen 8, The second filter screen 9, the punching bag 10, the fan 11, the dustproof sheet 12, the control switch 13 and the power cord 14, the inspection door 2 is hinged at the front of the box body 1, the ventilation window 3 is embedded on the right side of the top of the box body 1, and the mounting seat 5 is embedded in the upper right corner of the box body 1, the air intake tube 6 is embedded in the middle of the left side of the box body 1 horizontally, the left and right sides of the bottom of the mounting seat 5 are respectively connected with the first filter screen 8 and the second filter screen 9, and the air outlet tube 10 is horizontally embedded in the O...

Embodiment 2

[0035] In the spray dust suppression structure for a mobile dust collector of the present invention, the large pulley 422 and the small pulley 442 are on the same horizontal plane, and the large pulley 422 and the small pulley 442 are connected by a transmission belt 43, while the large pulley 422 and the small pulley 442 The size ratio of the special-shaped gear 462 is 5:1, which is convenient for the small pulley 442 to accelerate the rotation. The ratio of the outer diameter of the rear side of the special-shaped gear 462 to the turntable 425 is 1:3, and the outer surface of the special-shaped gear 462 is connected with the turntable 425 through the transmission belt 461. It is beneficial to drive the special-shaped gear 462 to carry out deceleration movement. The angle formed by the bottom side of the rectangular groove seat 71 from left to right and the horizontal ground is 15 degrees, which is convenient for the flow of water. The top surface of the water outlet connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com