Thick-wall 800H alloy machining equipment and machining method thereof

A technology of 800H and processing equipment, which is applied in the field of thick-walled 800H alloy processing, and can solve problems such as failure, uneven wall surface of thick-walled 800H alloy parts, and reduction of rebound deformation of ring-shaped thick-walled 800H alloy parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be further described below in conjunction with the drawings and embodiments.

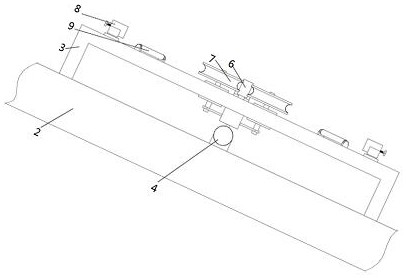

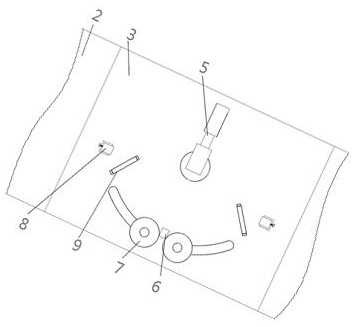

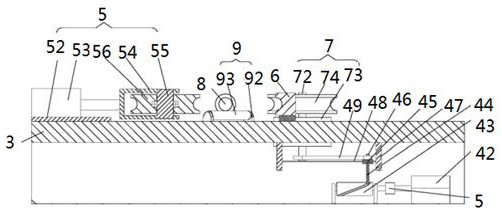

[0030] Such as Figure 1-Figure 5 As shown, the processing method of the thick-walled 800H alloy processing equipment includes the following steps:

[0031]Cuboid support seat 2, positioning frame 3, traction device 4, reflexion device 5, stop plate 6, rotating device 7, clamping device 8 and fixed pulley 9, the positioning frame 3 is assembled on the support seat 2, and the The positioning frame 3 is an inverted arch-shaped structure. The mirror image on the front wall of the top of the positioning frame 3 is provided with an arched through opening. There is a stop plate 6 between the equipment 7, the stop plate 6 is assembled on the positioning frame 3, the back of the stop plate 6 is provided with a semi-circular groove, and the positioning frame 3 is provided with a traction device 4 , the traction device 4 is assembled on the support base 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com