A Partition Die Compression Forming Method for Lightweight Alloy Thin-wall Curved Surface Parts

A light alloy, compression molding technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of large springback, uneven deformation, and inability to solve the problem of wrinkling in light alloy forming at room temperature, and achieve reduction The effect of zoned compression molding wrinkling tendency, reducing the degree of shape asymmetry, and improving the ability to resist instability and wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Five divisions-30-70-50-aluminum alloy-forming and quenching integration

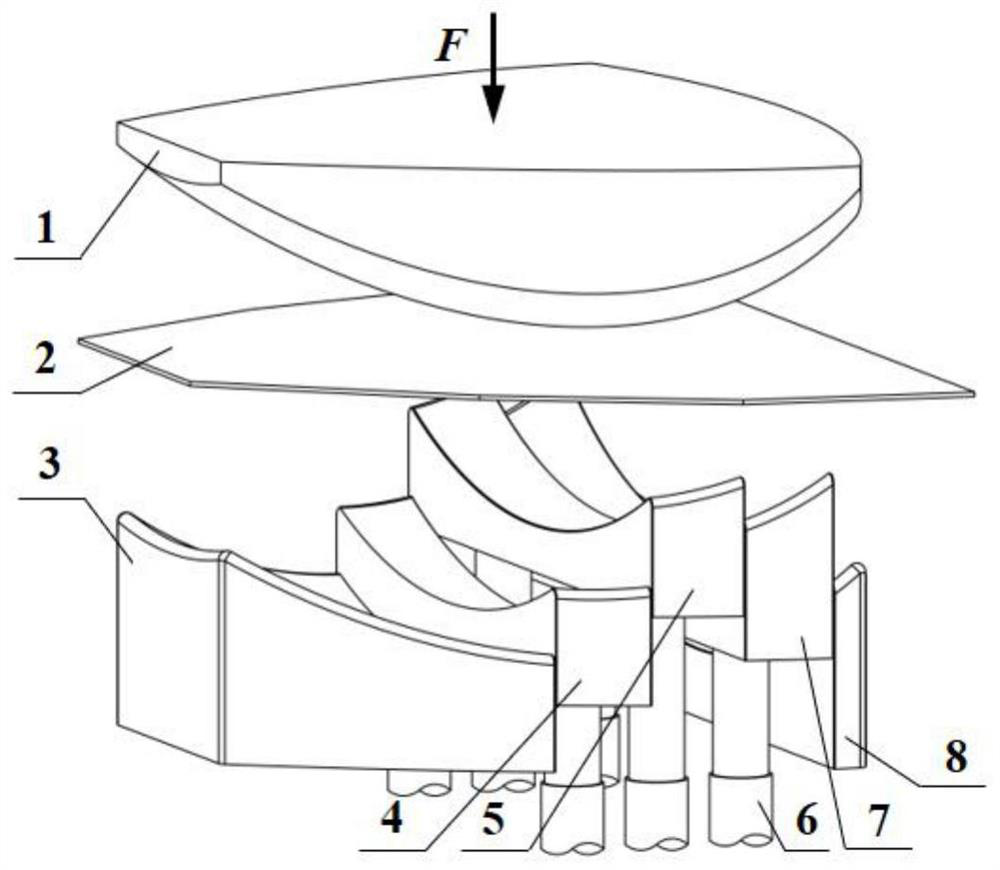

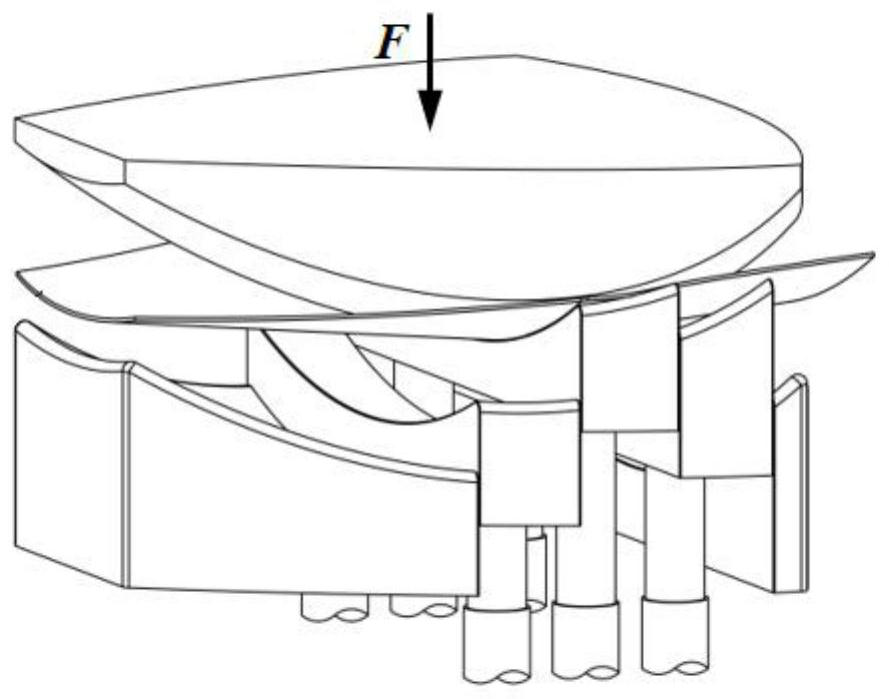

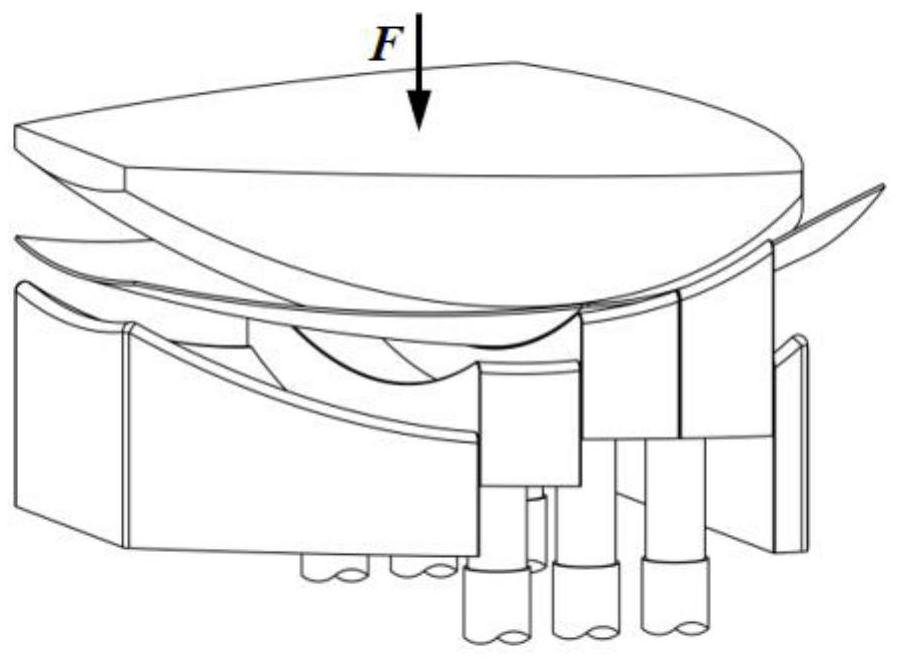

[0045] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6To illustrate, this special example of implementation provides a partition molding method for aluminum alloy curved surface parts. This method decomposes the large deformation of the entire region into small deformations of each partition, reduces the contact area and deformation difference of each partition, and reduces the The tangential compressive stress of each partition, thereby reducing the wrinkling of the formed part. The plate 2 is placed between the upper mold 1 and each partition mold, and the spring 6 is installed at the lower end of each partition mold to realize the elevation. The elevation height of the near big end partition 7 of the die is 50 mm, and the small end partition 3 of the lower die and the large end partition 8 of the lower die are not raised. The upper die 1 is pressed down, so...

Embodiment 2

[0053] Three partitions-30-titanium alloy-forming and quenching integration

[0054] combine Figure 7 To illustrate, this special example of implementation provides a partition molding method for titanium alloy curved surface parts. This method decomposes the large deformation of the entire region into small deformations of each partition, reduces the contact area and deformation difference of each partition, and reduces the The tangential compressive stress of each partition, thereby reducing the wrinkling of the formed part. The plate 2 is placed between the upper mold 1 and each partition mold, and the lower end of the middle partition 5 of the lower mold is equipped with a spring 6 to realize the elevation, and the height of the elevation is 30mm, and the small end partition 3 of the lower mold and the large end partition 8 of the lower mold are not raised. The upper mold 1 presses down, so that the middle area of the plate 2 sticks to the middle section 5 of the lower...

Embodiment 3

[0062] Five divisions-30-70-50-high strength steel-forming and quenching integration

[0063] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 To illustrate, this special example of implementation provides a method for the divisional compression molding of high-strength steel curved surface parts. This method decomposes the large deformation of the entire area into small deformations of each division, reduces the contact area and deformation difference of each division, and reduces the The tangential compressive stress of each partition, thereby reducing the wrinkling of the formed part. The plate 2 is placed between the upper mold 1 and each partition mold, and the spring 6 is installed at the lower end of each partition mold to realize the elevation. The elevation height of the near big end partition 7 of the die is 50 mm, and the small end partition 3 of the lower die and the large end partition 8 of the lower die are not raised. The uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com