Plastic vacuum forming machine

A technology for blister machines and racks, applied in the field of mechanical equipment, can solve problems such as poor product quality, achieve the effects of improving stability, reducing costs, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

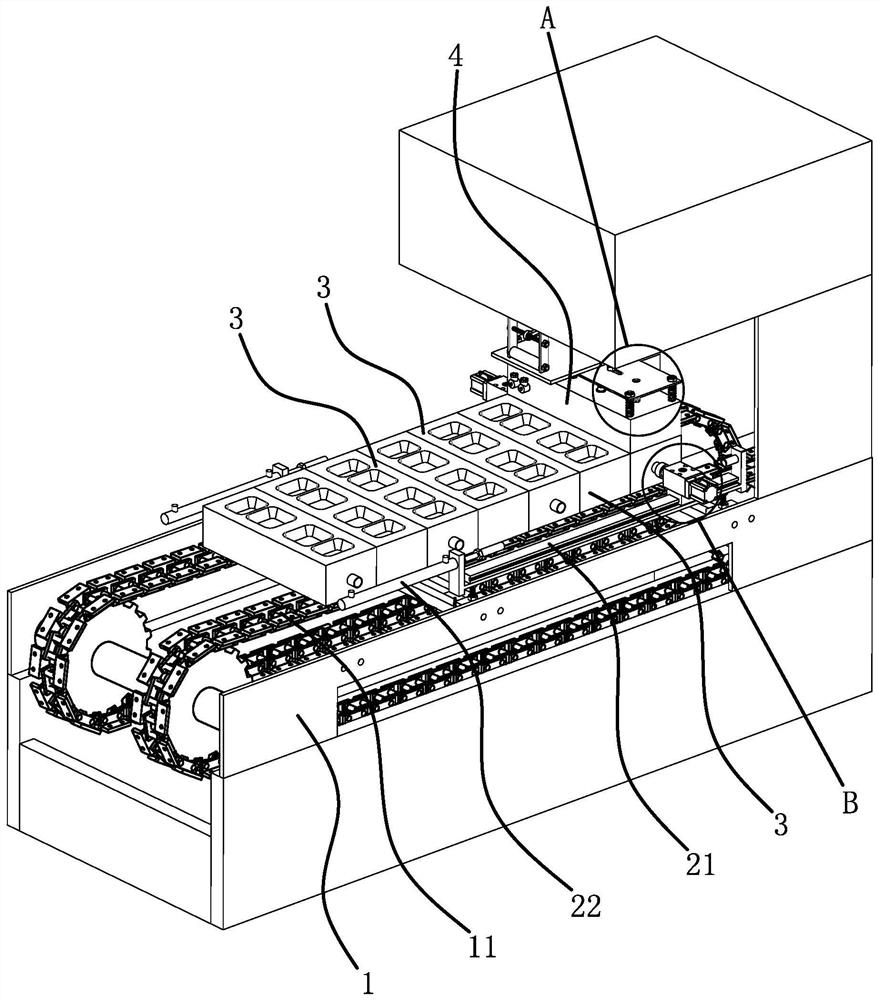

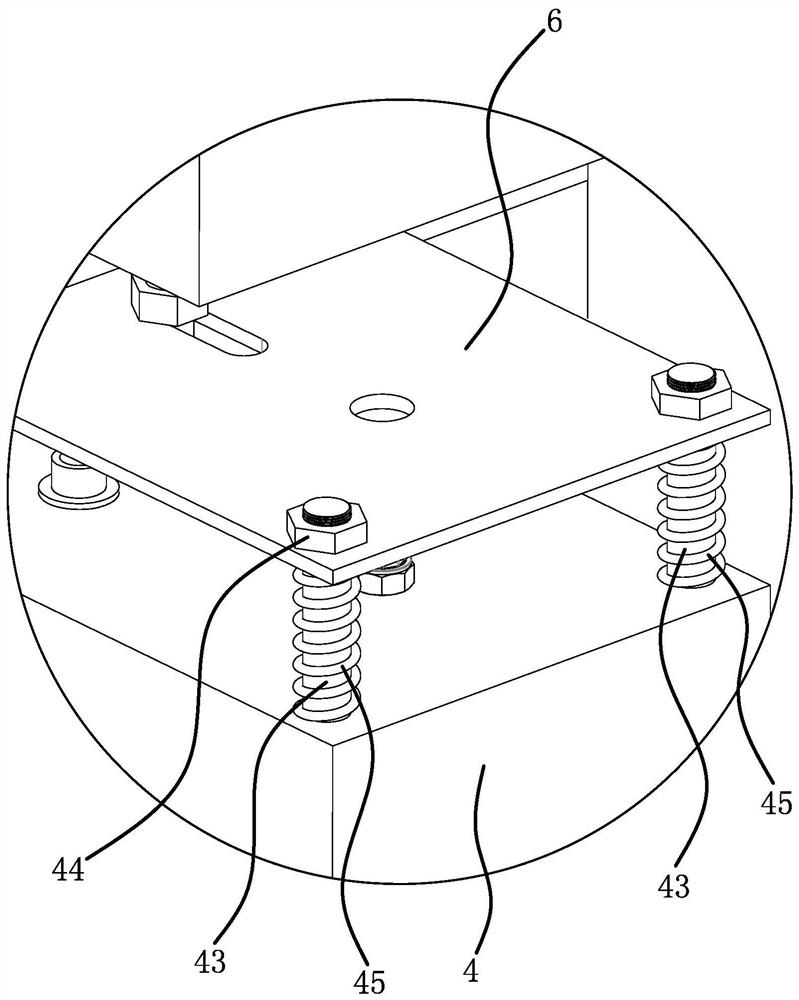

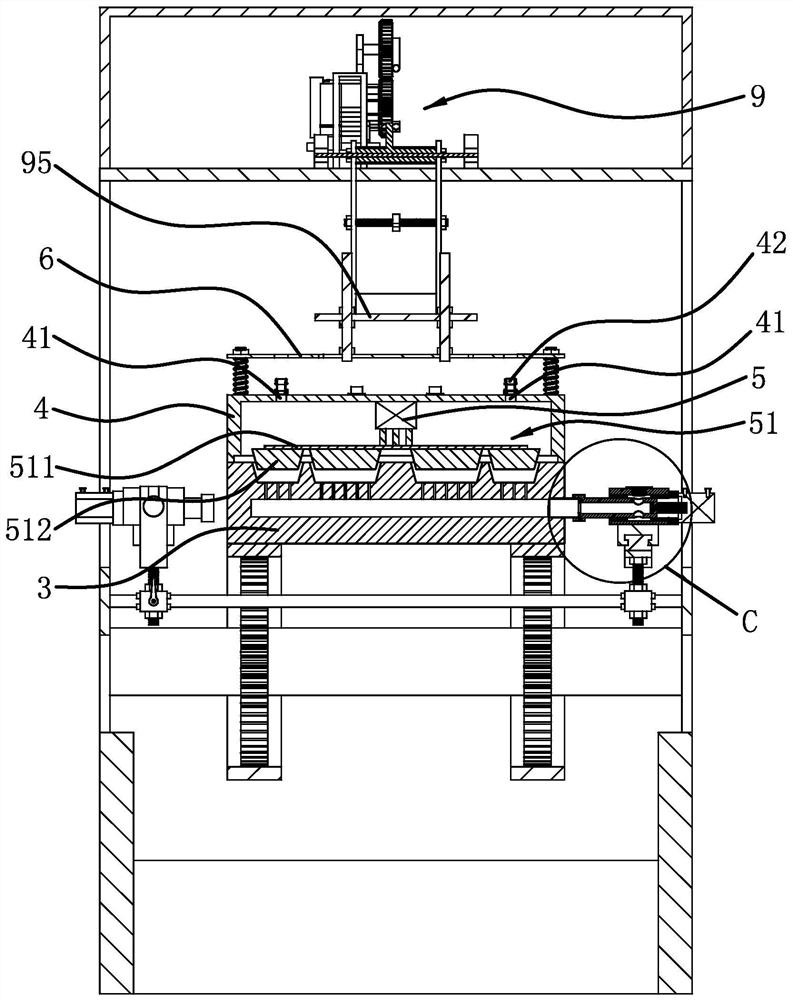

[0038] Such as figure 1 Shown, a kind of plastic suction machine comprises frame 1, is provided with conveying chain 11 on frame 1, is connected with a plurality of lower molds 3 on conveying chain 11, and these a plurality of lower molds 3 are arranged in sequence and along with conveying chain 11 Circular movement, when the lower mold 3 moves to the top, the opening of the lower mold 3 faces upwards, and the lower mold 3 is a die with an inner concave mold core inside, and has a flat upper end surface. The frame 1 is horizontally connected with a lifting plate 6 capable of lifting, on the lifting plate 6 is connected a patrix 4, the patrix 4 is in the shape of a rectangular frame, and the opening of the patrix 4 faces do...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap