Heat-stabilizing and pressure-stabilizing heating plate for full-automatic gilding press

A fully automatic hot stamping machine and heating plate technology, which is applied to the general parts of printing machinery, printing machines, rotary printing machines, etc., can solve problems such as overpressure, heating plate overheating, and affecting product quality, so as to increase friction and improve Cleaning effect, anti-silting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

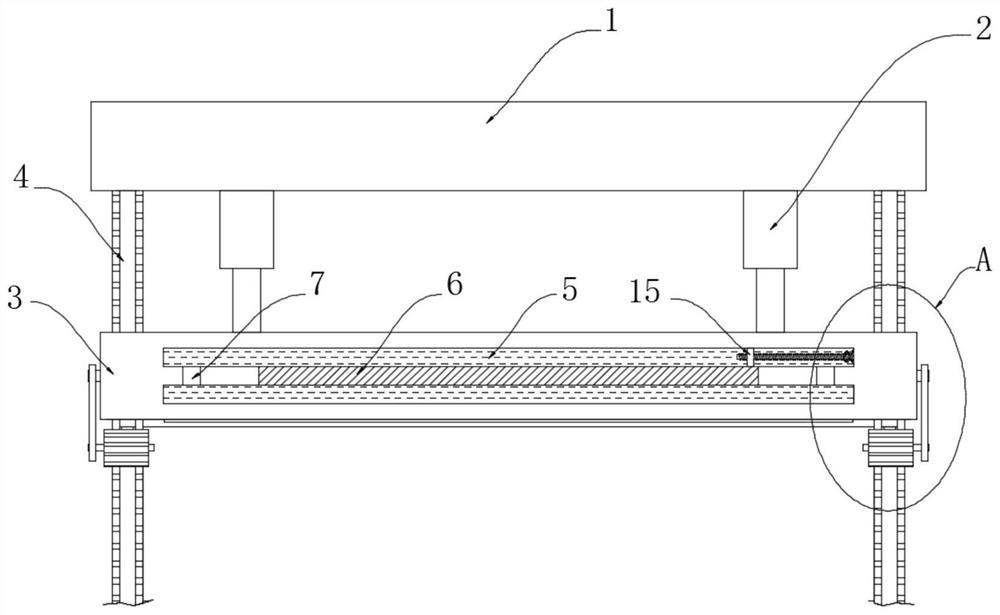

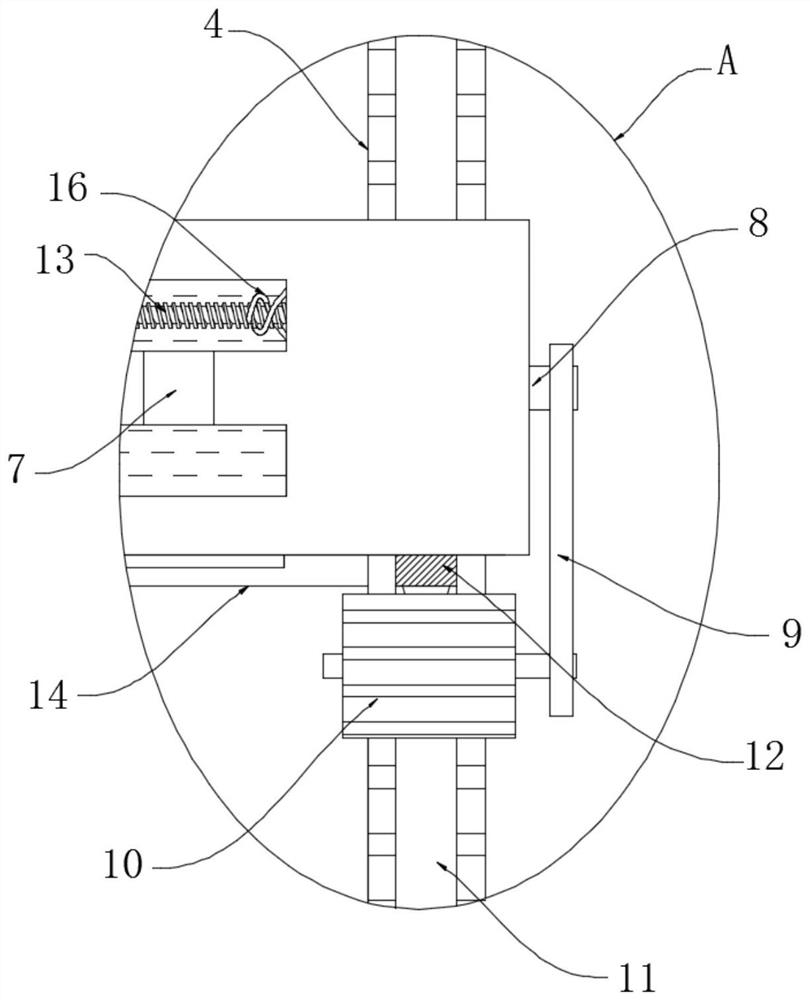

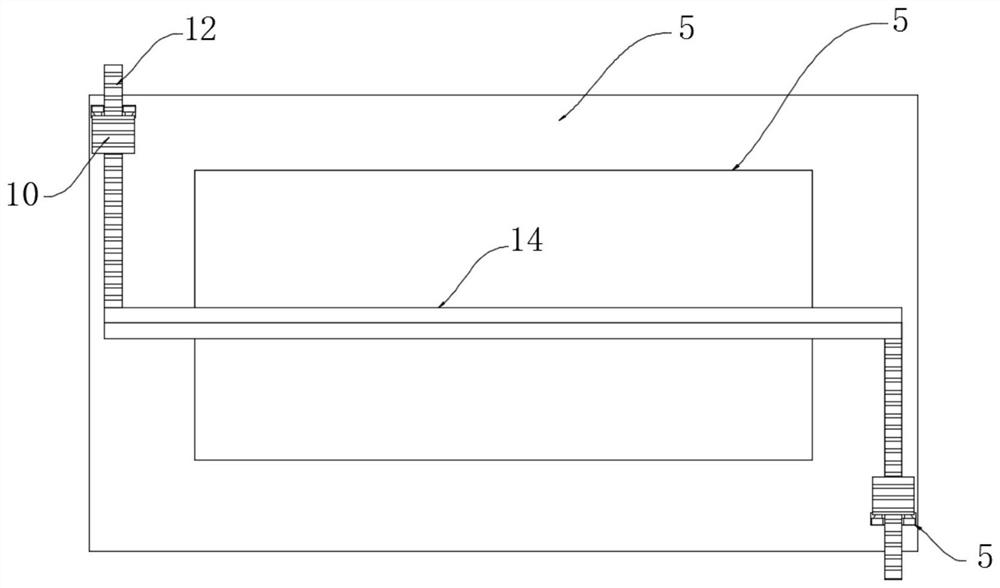

[0022] refer to Figure 1-3 , a heating plate with stable heat and pressure for a full-automatic hot stamping machine, comprising a frame 1 of a beam structure and a plurality of hydraulic cylinders 2, the plurality of hydraulic cylinders 2 are fixedly connected with a heating plate 3, and the inner wall of the heating plate 3 is provided with two A heating liquid chamber 5, the bottoms on both sides of the frame 1 are respectively fixedly connected with the first rack plates 4, the two first rack plates 4 all run through the inner wall of the heating plate 3, and the side walls on both sides of the heating plate 3 are respectively fixed Connected with a positioning rod 8, the positioning rod 8 is externally connected with a connecting rod 9, and the other end of the connecting rod 9 is connected to a gear 10 through a rotating shaft, and the gear 10 meshes with the first rack plate 4;

[0023] The first rack plate 4 is penetrated with a through groove 11, and the second rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com