Automatic gauze bag filling machine for cotton quilt batt

An automatic filling and gauze technology, which is applied in the direction of packaging, etc., can solve the problems of not being able to invest in improving the production line, not being suitable for mass production, and the appearance of the quilt is irregular, so as to improve the efficiency of automatic operation, good filling effect, and easy to promote The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

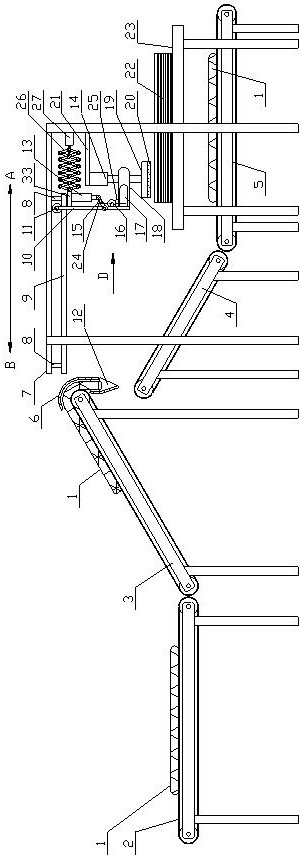

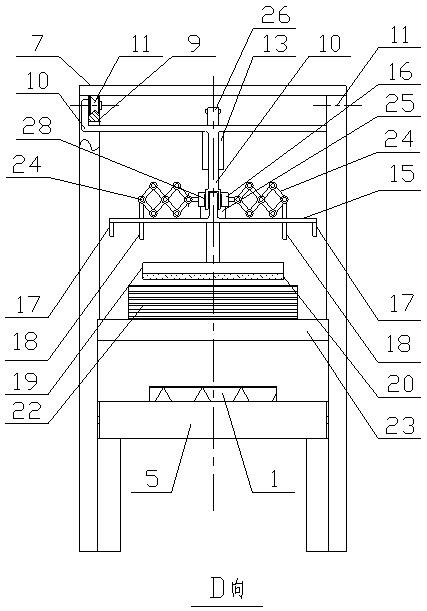

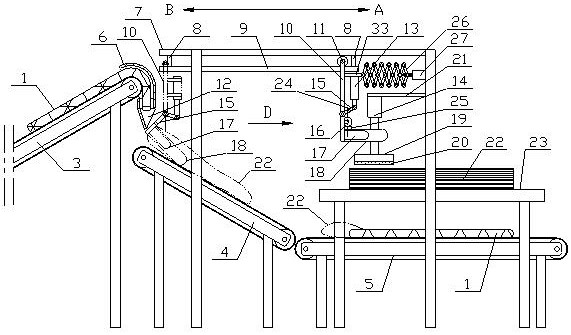

[0040] Such as Figure 1 to Figure 10 As shown, the quilt tire 1 can be transported in the same direction on the first conveyor belt 2, the second conveyor belt 3, the third conveyor belt 4, and the fourth conveyor belt 5; the first conveyor belt 2, the fourth conveyor belt 5 are Horizontal conveying, the second conveyor belt 3 is lifting conveying, and the third conveying belt 4 is descending conveying; the cover 6 is fixedly connected to the second conveyor belt 3 through the baffle hole 31, and the cover is fixed 6 has a baffle inlet 32 and a baffle outlet 12; the quilt 1 enters the quilt baffle 6 from the baffle inlet 32 on the second conveyor belt 3, and then exits from the baffle outlet 12; The third conveyor belt 4 is connected to the end of the outlet 12 of the deflector; the guide rail fixing rod 8, the second cylinder bracket 21, and the fourth cylinder 27 are fixed on the grabbing mechanism bracket 7; the guide rail 9 is fixed on the guide rail fixing rod 8, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com