Automatic pouring slurry for coke oven top

An automatic and grouting technology, applied in the field of grouting materials, can solve the problems of poor self-flow, poor sealing, and serious sedimentation of the grouting, and achieve the effects of good fluidity, prevention of smoke and fire, and excellent anti-settling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

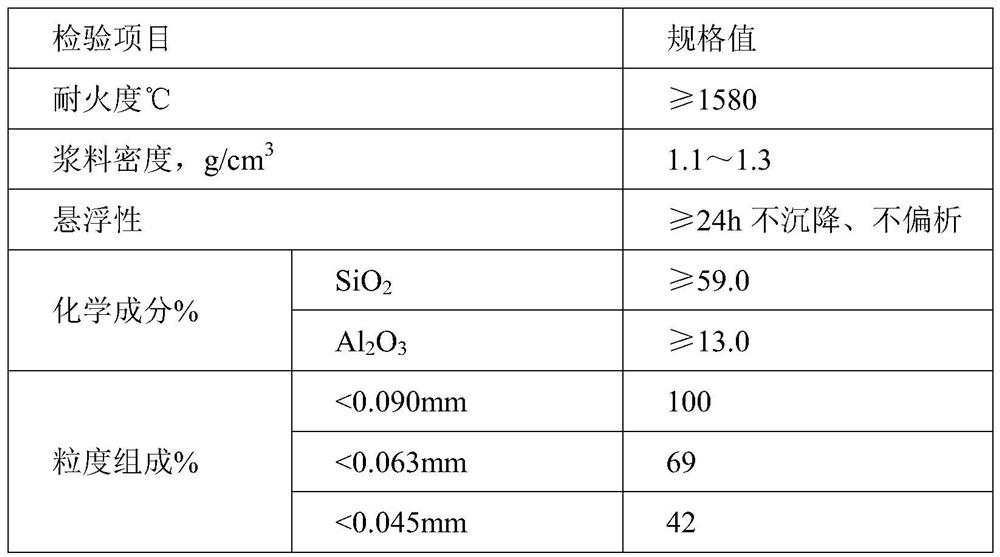

[0027] The automatic grouting material for coke oven top is composed of aggregate and water. The weight ratio of aggregate to water is 1:1.1. When the grouting aggregate is used on site, it is first prepared as slurry. The percentage by weight includes 30% of refractory clinker powder, 30% of refractory clay, 35% of refractory pottery clay, 3.5% of plasticizer, and 1.5% of sodium tripolyphosphate. The refractory clinker powder is clinker powder prepared by calcining 70wt% kaolin and 30wt% high alumina bauxite at a high temperature of 1300°C. The plasticizer is 50% by mass of sodium silicate and 50% of aluminum phosphate, and the suspending agent is sodium tripolyphosphate.

[0028] When weighing the aggregate, the aggregate needs to be classified and crushed. After crushing, the particle size composition is as follows: the particle size with a diameter of <0.090mm accounts for 100%, the particle size with a diameter of <0.063mm accounts for 69%, and the particle size with a dia...

Embodiment 2

[0031] The automatic grouting material is used for the roof of the coke oven. The automatic grouting material is composed of aggregate and water. The weight ratio of aggregate to water is 1:1.4. The percentage by weight includes 50% of refractory clinker powder, 20% of refractory clay, 28.5% of refractory pottery clay, 1% of plasticizer, and 0.5% of sodium tripolyphosphate. The refractory clinker powder is clinker powder prepared by calcining 90wt% kaolin and 10wt% high alumina bauxite at a high temperature of 1500°C, and the plasticizer is 68% sodium silicate and 32% aluminum phosphate in mass percentage.

[0032] When weighing the aggregate, the aggregate needs to be graded and crushed. After crushing, the particle size composition is as follows: the particle size with a diameter of <0.090mm accounts for 100%, the particle size with a diameter of <0.063mm accounts for 75%, and the particle size with a diameter of <0.045mm accounts for 45%. , crushed and mixed evenly to make ...

Embodiment 3

[0035]The automatic grouting material is used for the top of the coke oven. The automatic grouting material is composed of aggregate and water. The weight ratio of aggregate to water is 1:1.2. The percentage by weight includes 45% of refractory clinker powder, 15% of refractory clay, 35% of refractory pottery clay, 1% of plasticizer, and 4% of sodium tripolyphosphate. The refractory clinker powder is clinker powder prepared by calcining 85wt% kaolin and 15wt% high alumina bauxite at a high temperature of 1400°C, and the plasticizer is 64% sodium silicate and 36% aluminum phosphate in mass percentage.

[0036] When weighing the aggregate, the aggregate needs to be graded and crushed. After crushing, the particle size composition is as follows: the particle size with a diameter of <0.090mm accounts for 100%, the particle size with a diameter of <0.063mm accounts for 72%, and the particle size with a diameter of <0.045mm accounts for 50%. , crushed and mixed evenly to make grouti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractory | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com