Vacuum exhaust device and vacuum exhaust method

A vacuum exhaust and vacuum technology, applied in the field of vacuuming, can solve the problems of low exhausting and vacuuming efficiency of exhaust devices, unstable yield, complex structure, etc., to improve the vacuuming efficiency and vacuuming yield, guarantee Accuracy and consistency, simple construction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

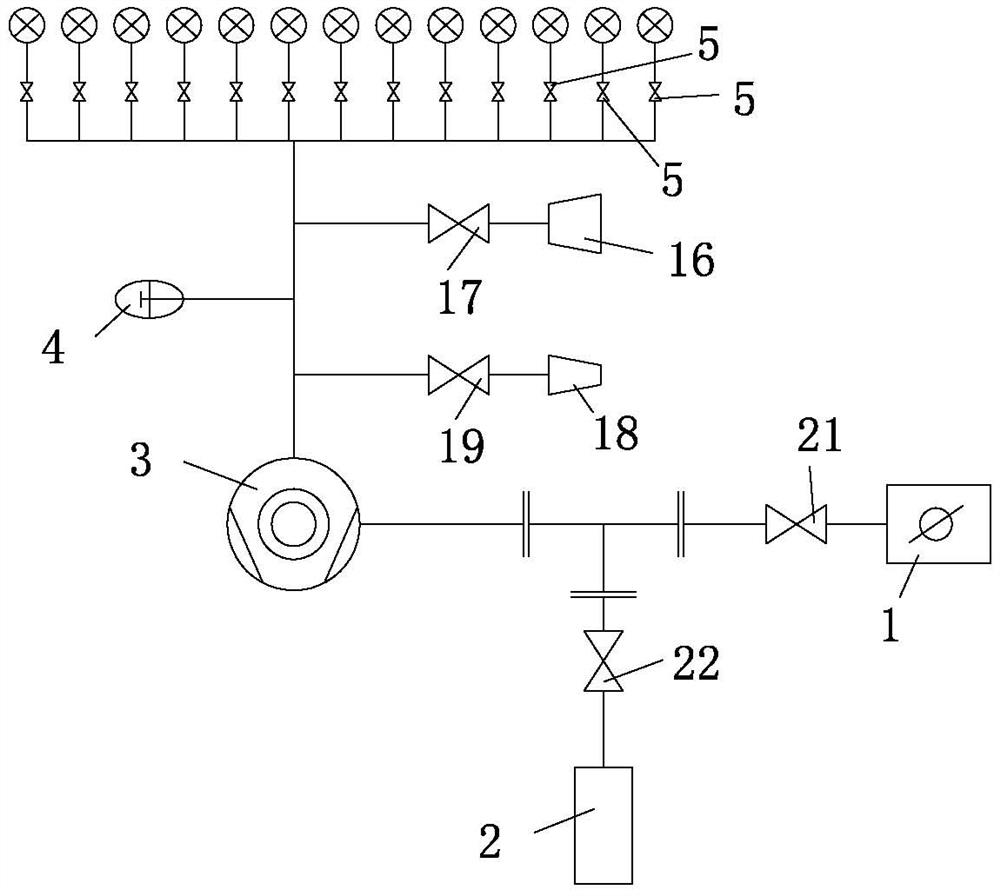

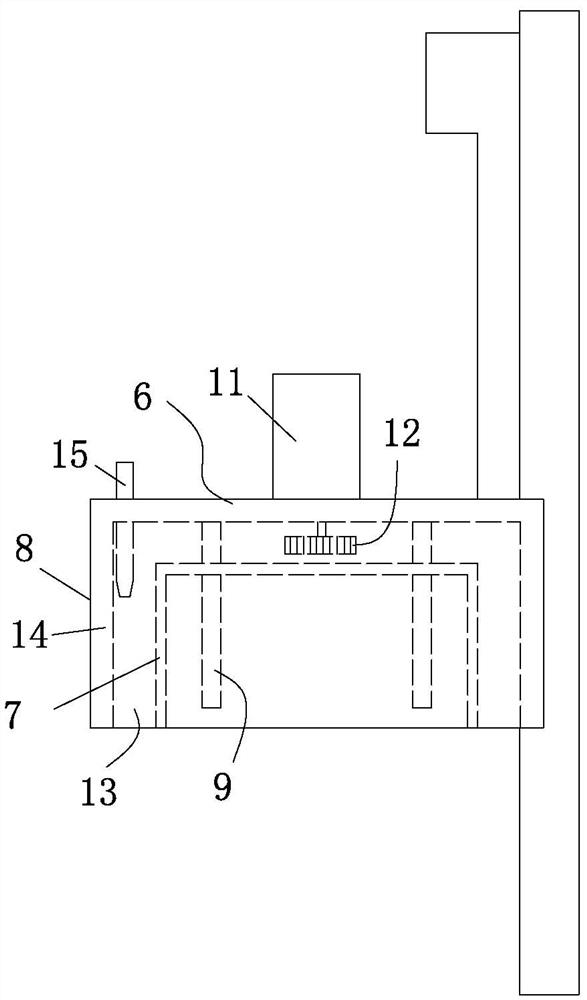

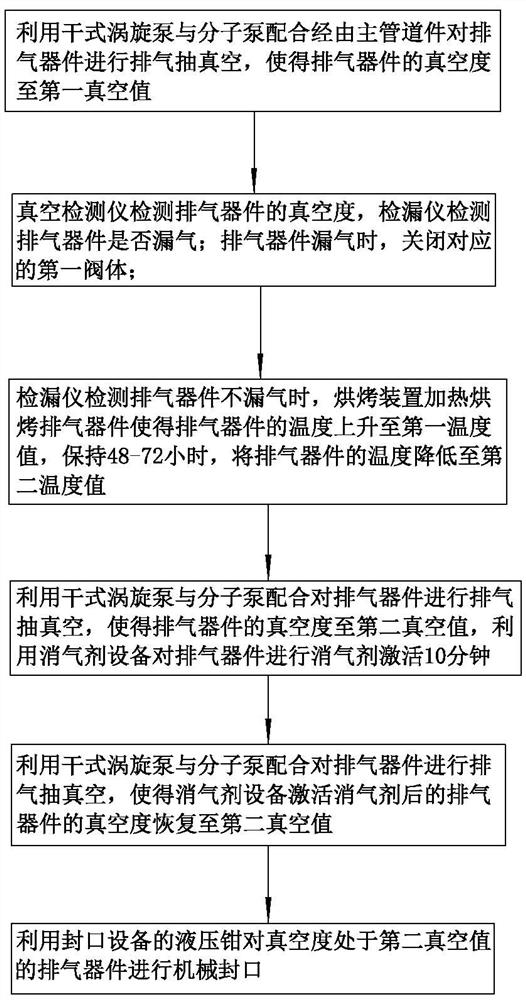

[0040] see Figure 1 to Figure 3 As shown, a vacuum exhaust device of the present invention includes a main pipe fitting, a dry scroll pump 1, a leak detector 2, a molecular pump 3, a vacuum detector 4 and a plurality of first valve bodies 5, and the dry scroll pump The rotary pump 1 communicates with the main pipeline via the molecular pump 3 . Preferably, the main pipe part is made of stainless steel, and the main pipe part is a hollow pipe part. According to actual needs, the dry scroll pump 1 communicates with the molecular pump 3 via a bellows. Preferably, the bellows is made of stainless steel. On the one hand, the high strength of stainless steel is used to prevent the defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com