Phosphogypsum floor heating box

A phosphogypsum and floor heating technology, applied in central heating components, household heating, space heating and ventilation details, etc., can solve problems such as potential safety hazards, increased energy consumption, damage to floor heaters, floor heater damage, etc., to achieve Easy to buy, save electricity, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

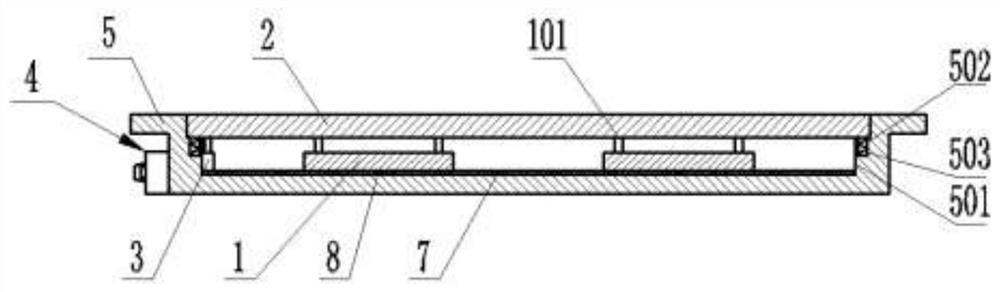

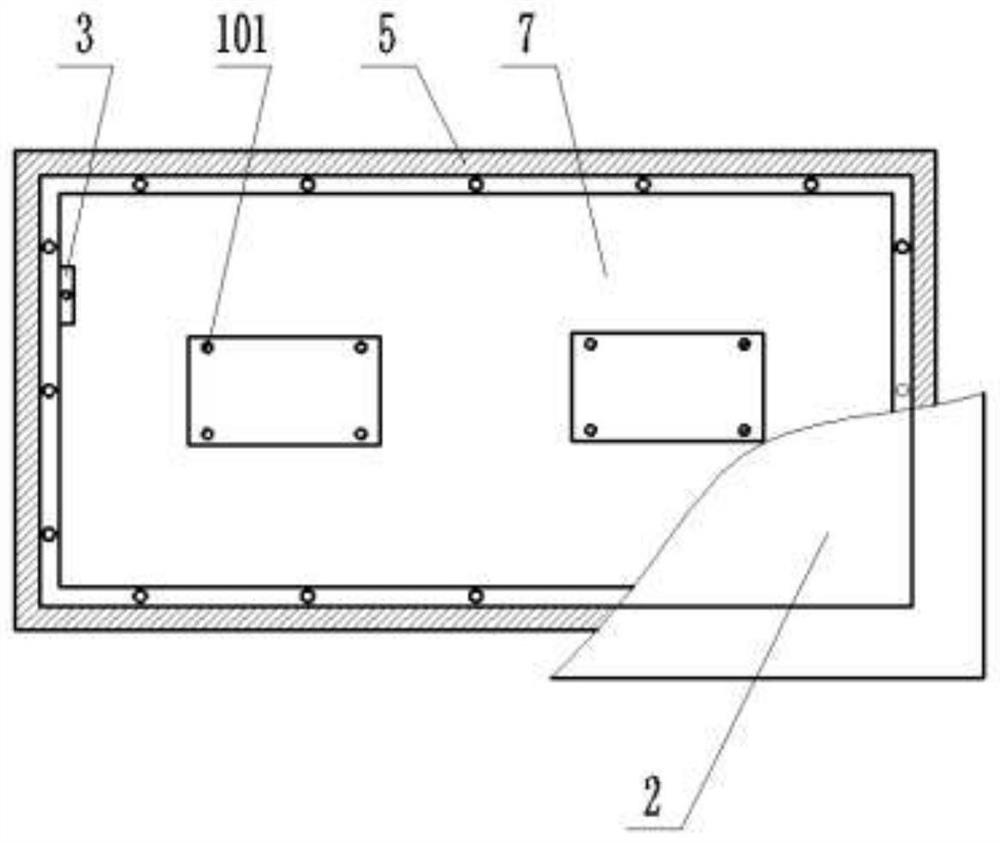

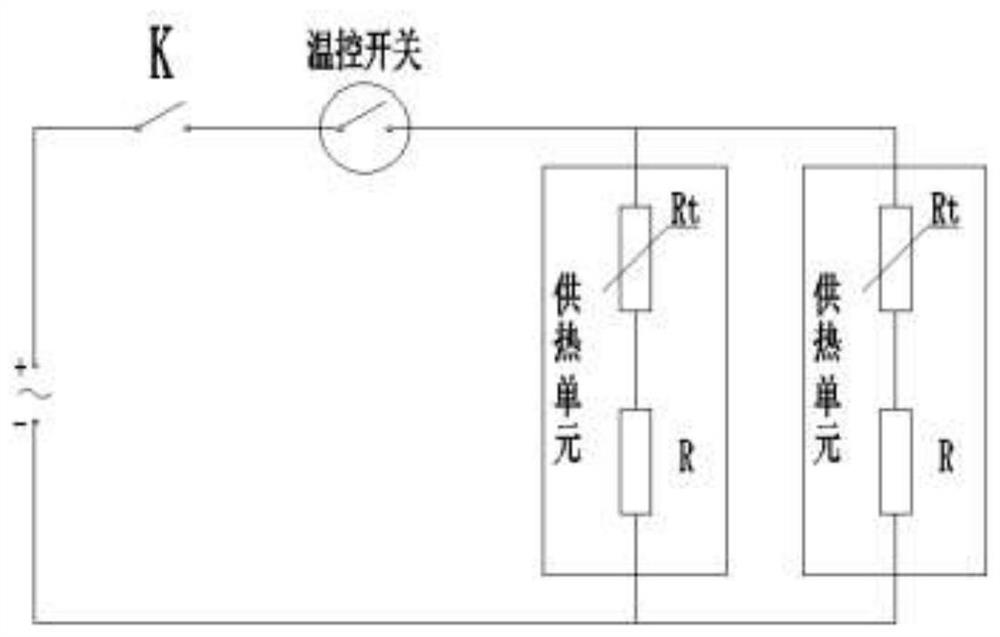

[0021] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a phosphogypsum floor heating oven, which includes a mica heating plate 1, a floor heating plate 2, a proximity switch 3, a control device 4, and a box body 5 with an opening at the top. The floor heating plate 1 is made of phosphogypsum material and passed through a press It is integrally pressed and formed. The open end of the box body 5 is provided with a step 501. Several proximity switches 3 are installed on the edge of the step 501. The floor heating plate 2 is placed on the step 501 and the open end of the box body 5 is covered. The mica heating plate 1 is installed Inside the box body 5 , the control device 4 is installed on the outer wall of the box body 5 , and the proximity switch 3 and the proximity switch 3 are both electrically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com