Non-contact railway relay supporting piece gap measuring system and method

A non-contact, measurement system technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of low efficiency, large subjective influence of measurement results, negative influence of relay parameters, etc., to achieve high efficiency, avoid adverse effects, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

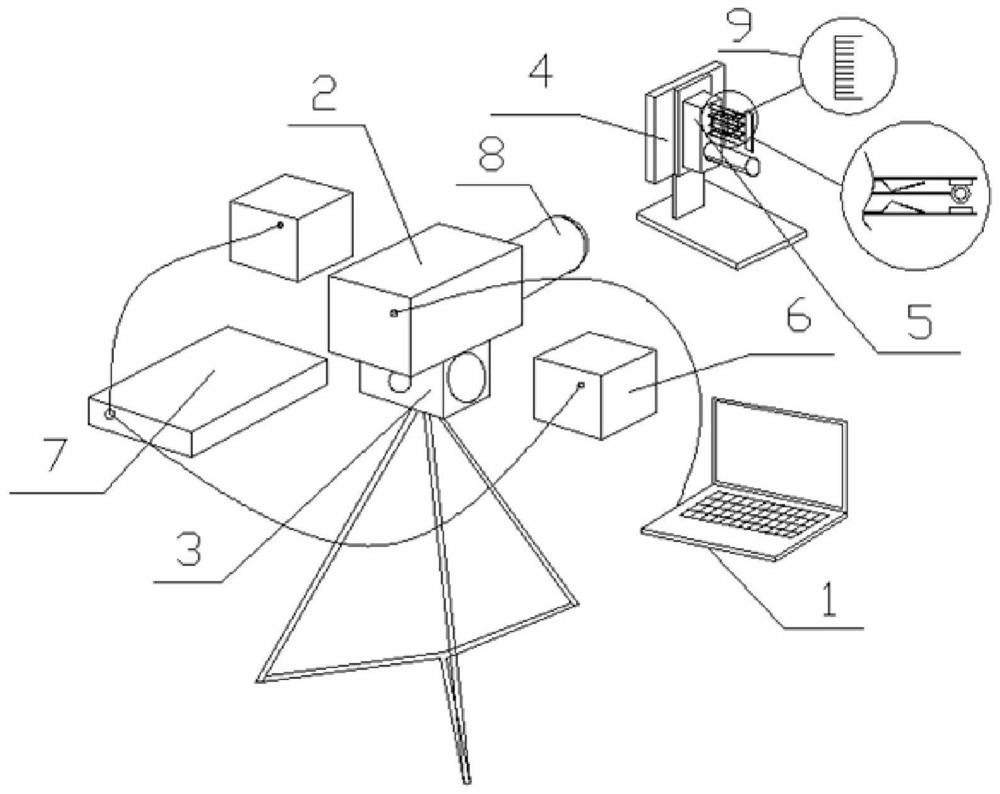

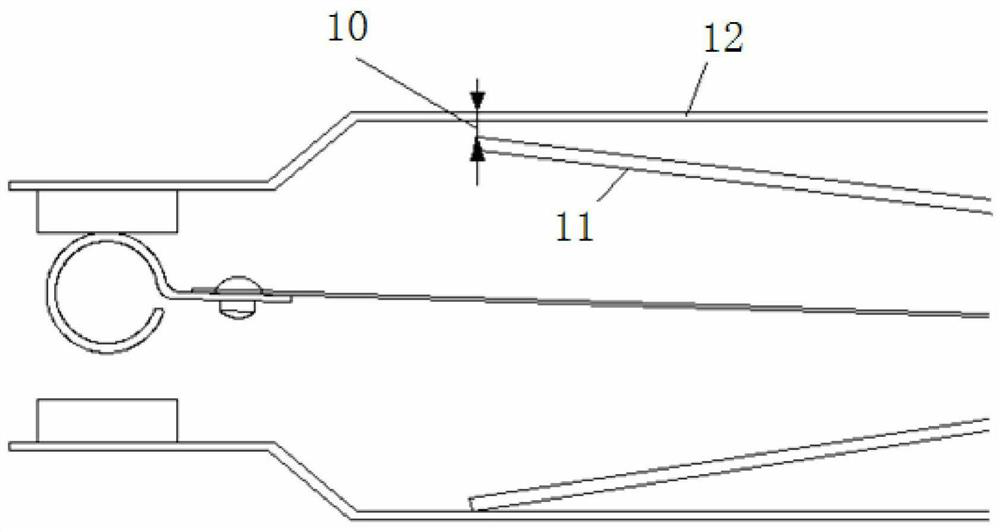

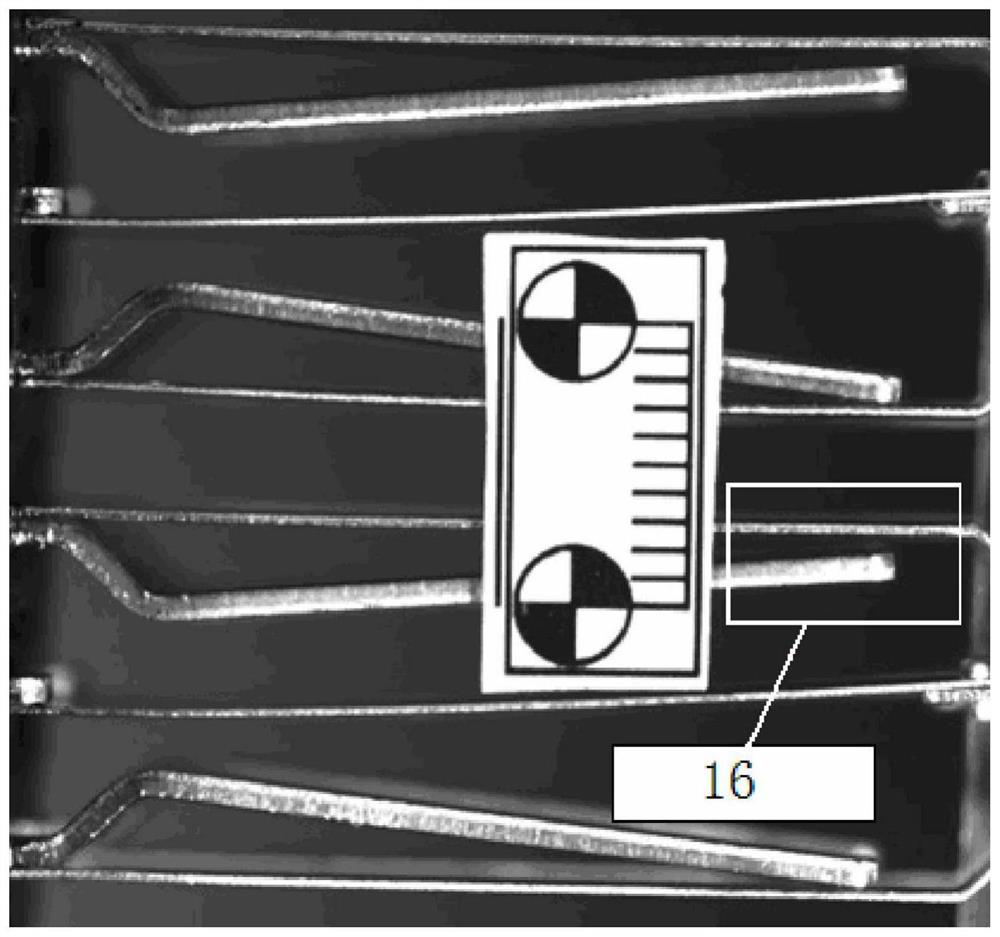

[0047] Such as figure 1 As shown, the present invention provides a non-contact measuring system for railway relay pallet gaps, including a computer 1, a CCD image acquisition sensor 2, an adjustment assembly 3, a railway relay contact alignment device base 4, parallel light lighting equipment 5, and a CCD The camera lens, wherein the tested product is inserted on the base 4 of the railway relay contact uniformity device, and the CCD image acquisition sensor is installed on one side of the tested product through the adjustment component for image acquisition; parallel light lighting equipment is installed on both sides of the CCD image acquisition sensor The CCD camera lens 8 is connected on the CCD image acquisition sensor 2; the scale 9 is pasted on the supporting piece and the reed on the side of the railway relay.

[0048] In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com