High-precision rolling bearing friction torque testing device and method

A rolling bearing and friction torque technology, applied in the field of friction torque testing devices, can solve problems such as the test effect is far from the expected test requirements, difficult friction torque test, poor test stability, etc., to optimize the fixing method, reduce friction, and improve positioning. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with accompanying drawing.

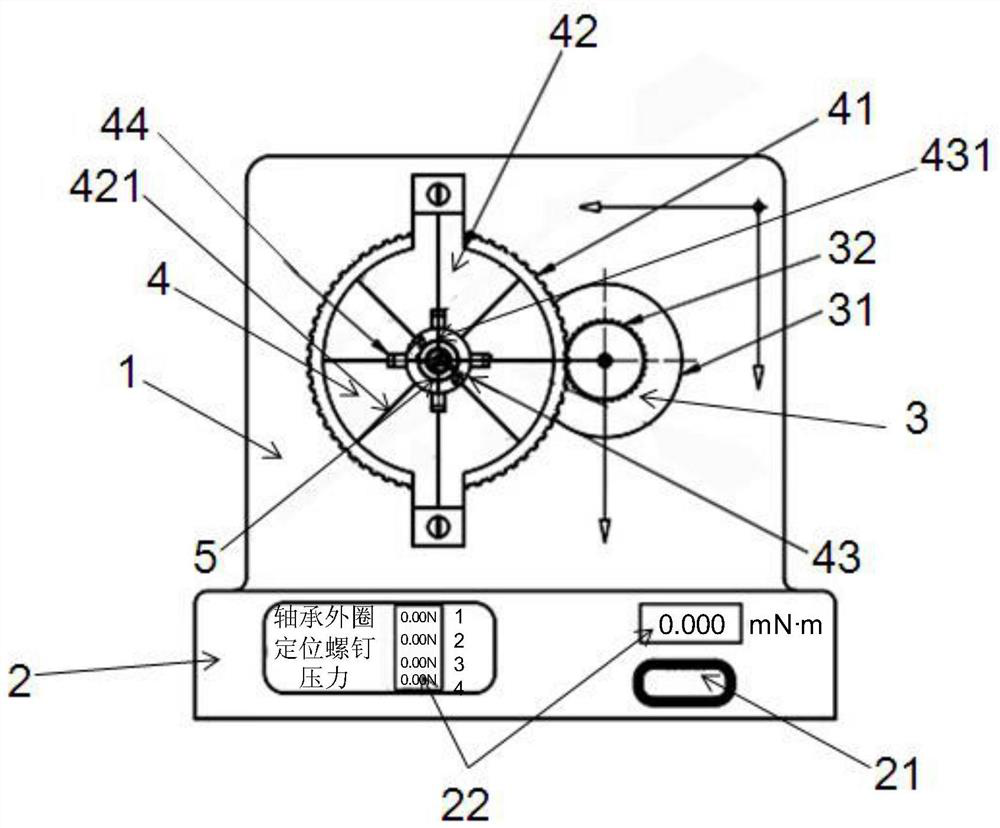

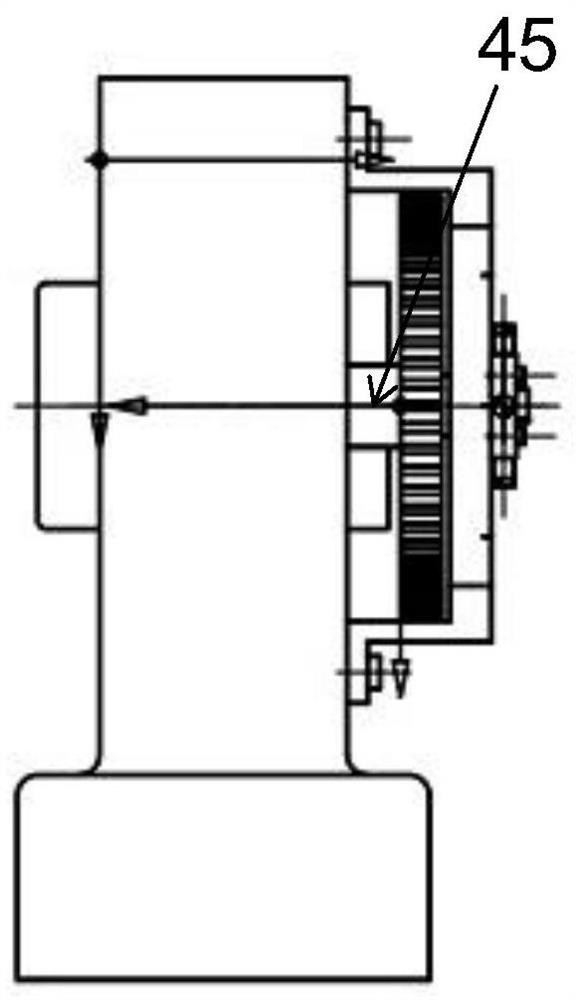

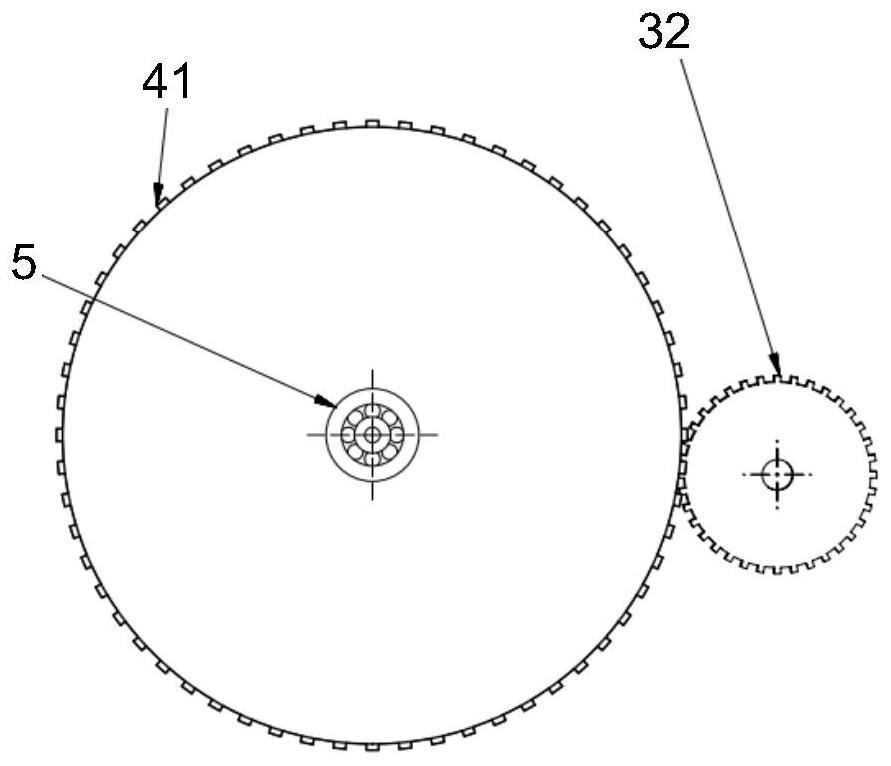

[0070] The high-precision rolling bearing friction torque testing device provided by the present invention increases the size of the driving wheel 32, the driven wheel 41, and the scale compass 42 in sequence, and amplifies the tiny friction through the principle of hierarchical amplification, so as to improve the resolution and accuracy of the test. , and the application of the graduated compass 42 can also realize the uniform distribution of multiple test positions. Such as Figure 1 to Figure 7 As shown, the test device includes a frame 1, an operation display panel 2, a power assembly 3 and a test assembly 4; the operation display panel 2 is arranged on the frame 1; the operation display panel 2 is provided with mutually electrically connected The main switch 21 and the display screen 22; the power assembly 3 includes a motor 31 and a driving wheel 32; the motor 31 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com