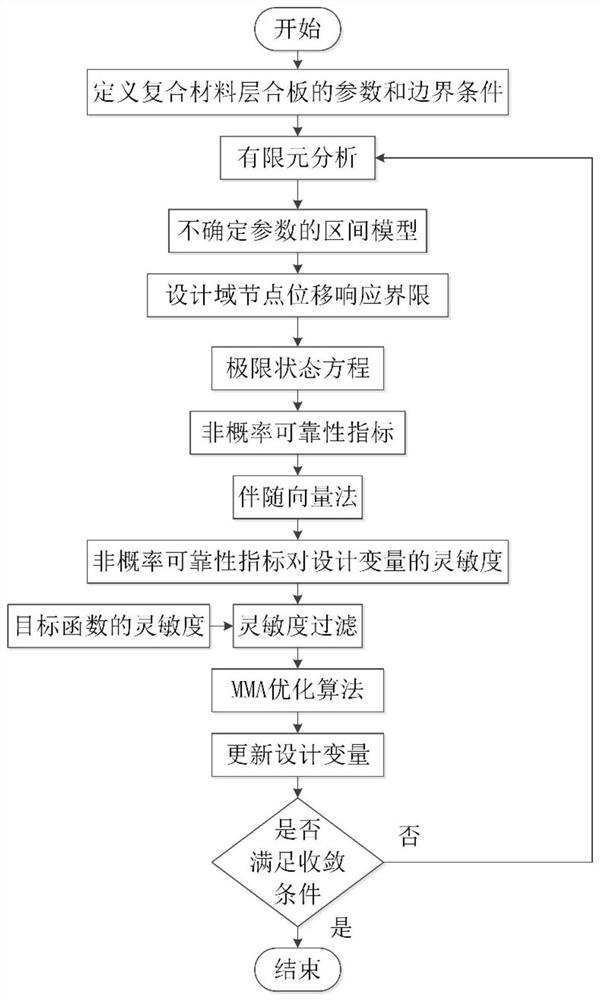

Composite laminate structure non-probabilistic reliability topological optimization method based on interval uncertainty

A composite material layer and uncertainty technology, applied in probabilistic CAD, design optimization/simulation, instruments, etc., to reduce economic costs and improve safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

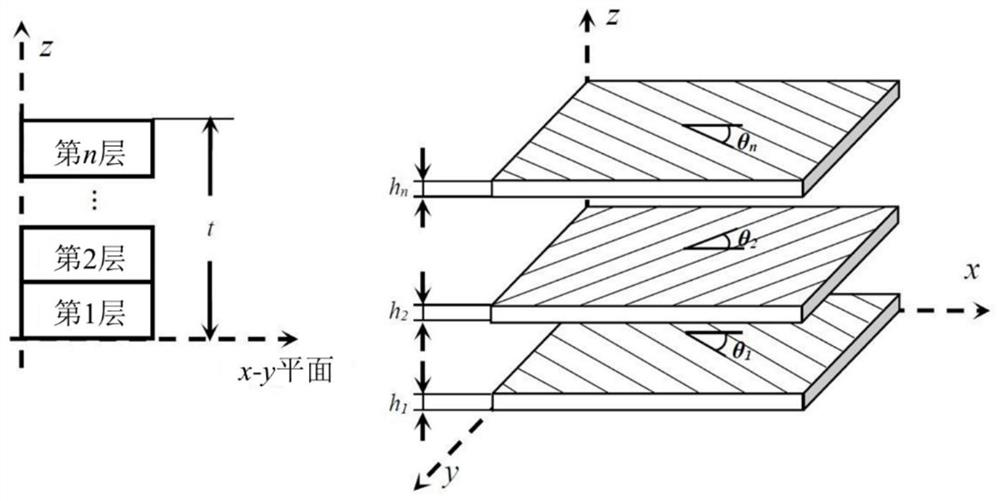

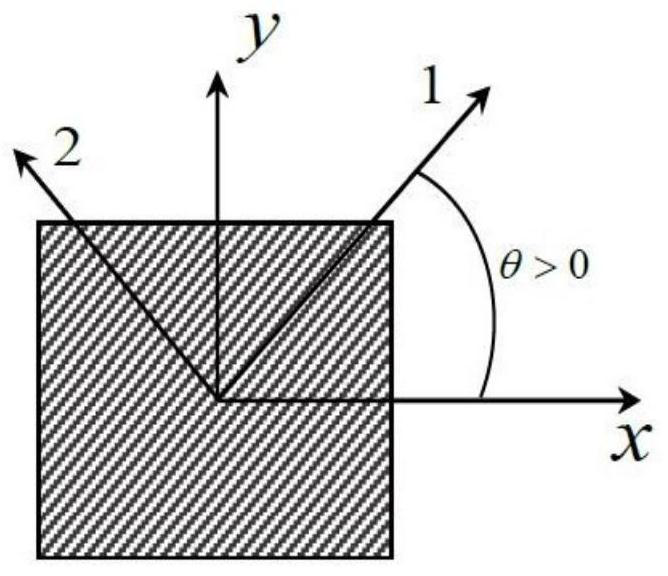

[0160] In this example, the carbon fiber composite material rib structure composed of MT300-3k / 603A unidirectional plates is considered for the topology optimization design under the structural stiffness. Displacement reliability as a constraint. Planar 4-node elements are used in the finite element analysis, and the design domain is divided into 7241 elements. The material parameters of MT300-3k / 603A one-way plate are shown in Table 1. Composite rib structure and boundary conditions such as Figure 8 shown. There are 5 layers of composite laminates, the laying angles of each layer are 0° / -45° / 90° / -45° / 0°, and the thickness of each layer is 0.25mm. The loads are 50N, 50N, 50N and -50N respectively, and the permissible displacements are 4mm, 1mm, 4mm and -0.1mm respectively. When conducting reliability topology optimization design, there is a 5% dispersion in consideration of load, laminate material properties and allowable displacement. The topological configurations of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com