Steel bar straightening machine for building machine

A steel bar straightening machine and construction machinery technology, which is applied in the direction of mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of conveying blockage, falling on it, and rough surface of steel bars, so as to avoid pollution, The effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

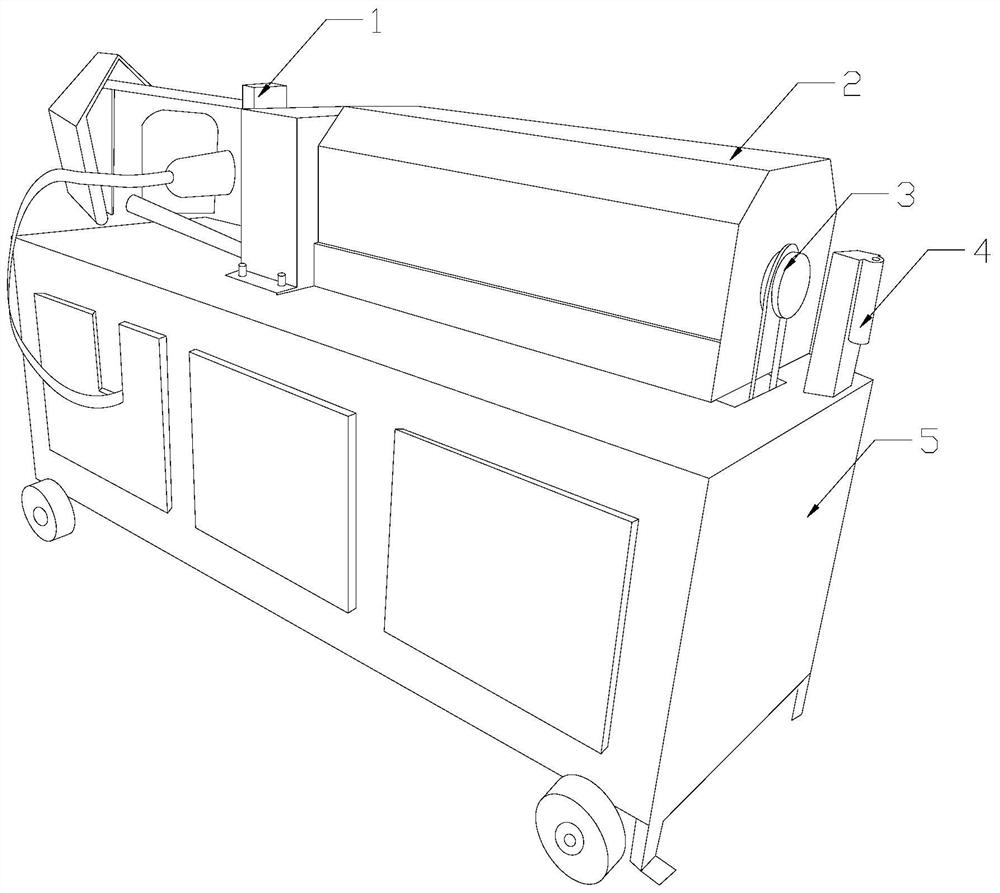

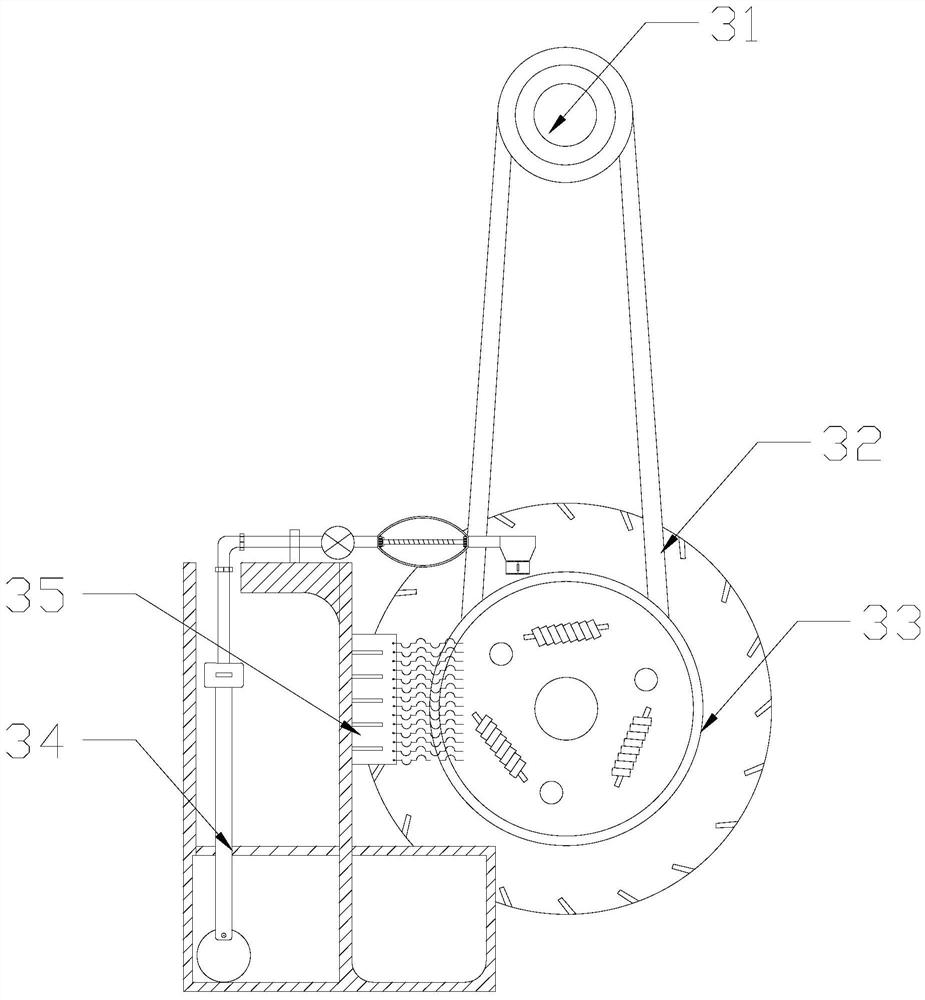

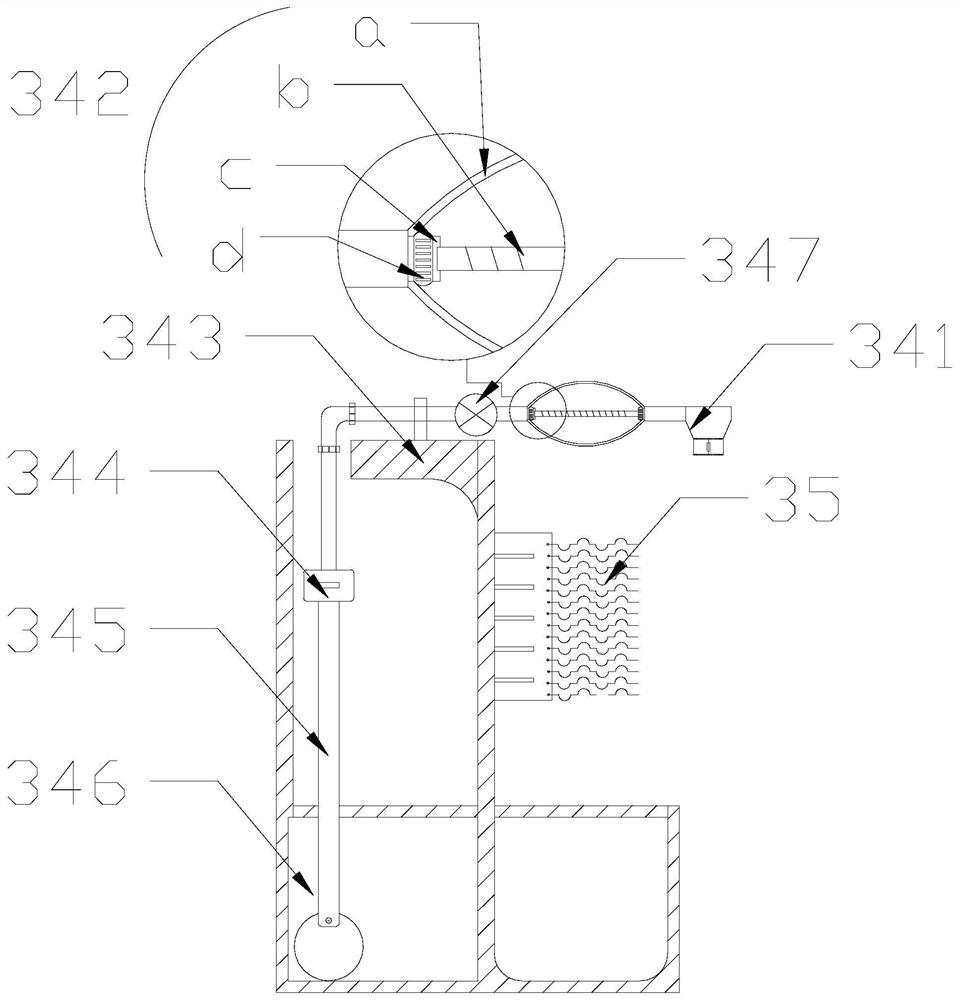

[0027] see Figure 1-Figure 5 , a steel bar straightening machine for construction machinery. The invention provides a steel bar straightening machine for construction machinery. Its structure includes a straightening seat 1, a steel bar delivery box 2, a transmission chain structure 3, a pillar 4, and a body 5. The top of the body 5 is equipped with a steel bar delivery box 2, a straightening seat 1 is installed on one side of the steel bar delivery box 2, and a transmission chain structure 3 is installed at the other end of the steel bar delivery box 2, and the transmission chain structure 3 is installed A pillar 4 is vertically installed on the top surface of the side of the body 5. The transmission chain structure 3 is composed of a secondary wheel 31, a transmission chain 32, a driving wheel 33, a lubricator 34, and a friction head 35. The driving wheel 33 is installed On the body 5, an auxiliary wheel 31 is arranged directly above the driving wheel 33, and the auxiliary ...

Embodiment 2

[0035] see Figure 1-Figure 5 , a steel bar straightening machine for construction machinery. The invention provides a steel bar straightening machine for construction machinery. Its structure includes a straightening seat 1, a steel bar delivery box 2, a transmission chain structure 3, a pillar 4, and a body 5. The top of the body 5 is equipped with a steel bar delivery box 2, a straightening seat 1 is installed on one side of the steel bar delivery box 2, and a transmission chain structure 3 is installed at the other end of the steel bar delivery box 2, and the transmission chain structure 3 is installed A pillar 4 is vertically installed on the top surface of the side of the body 5. The transmission chain structure 3 is composed of a secondary wheel 31, a transmission chain 32, a driving wheel 33, a lubricator 34, and a friction head 35. The driving wheel 33 is installed On the body 5, an auxiliary wheel 31 is arranged directly above the driving wheel 33, and the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com