Plastic film slicer

A technology of plastic film and slicer, applied in metal processing and other directions, can solve the problems of inappropriate cutting film needs and high maintenance costs, improve cutting efficiency and finished product qualification rate, reduce manufacturing and maintenance costs, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

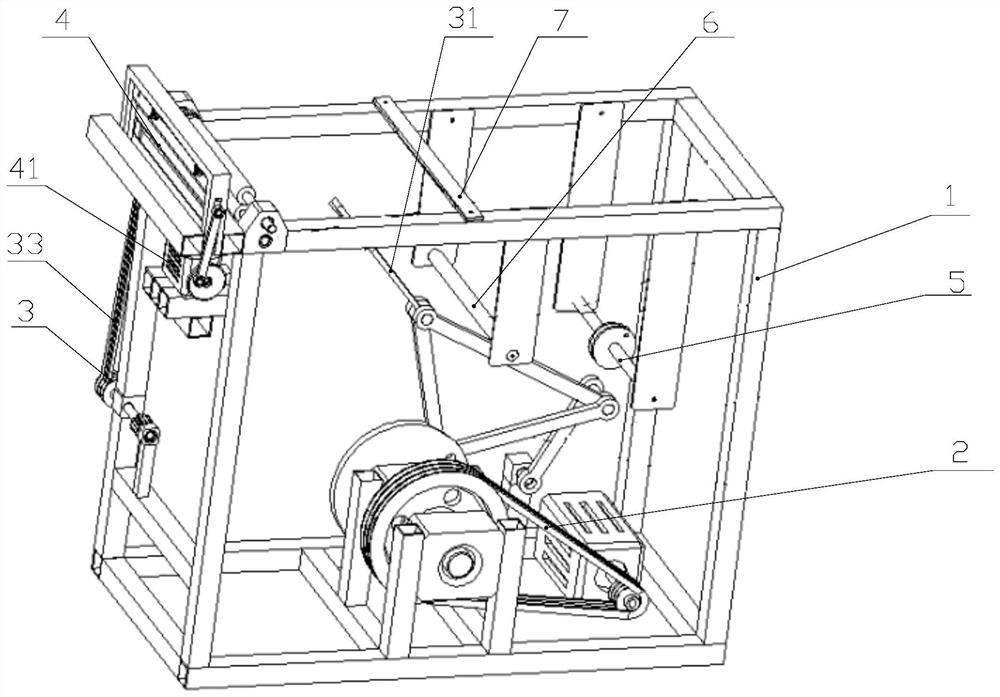

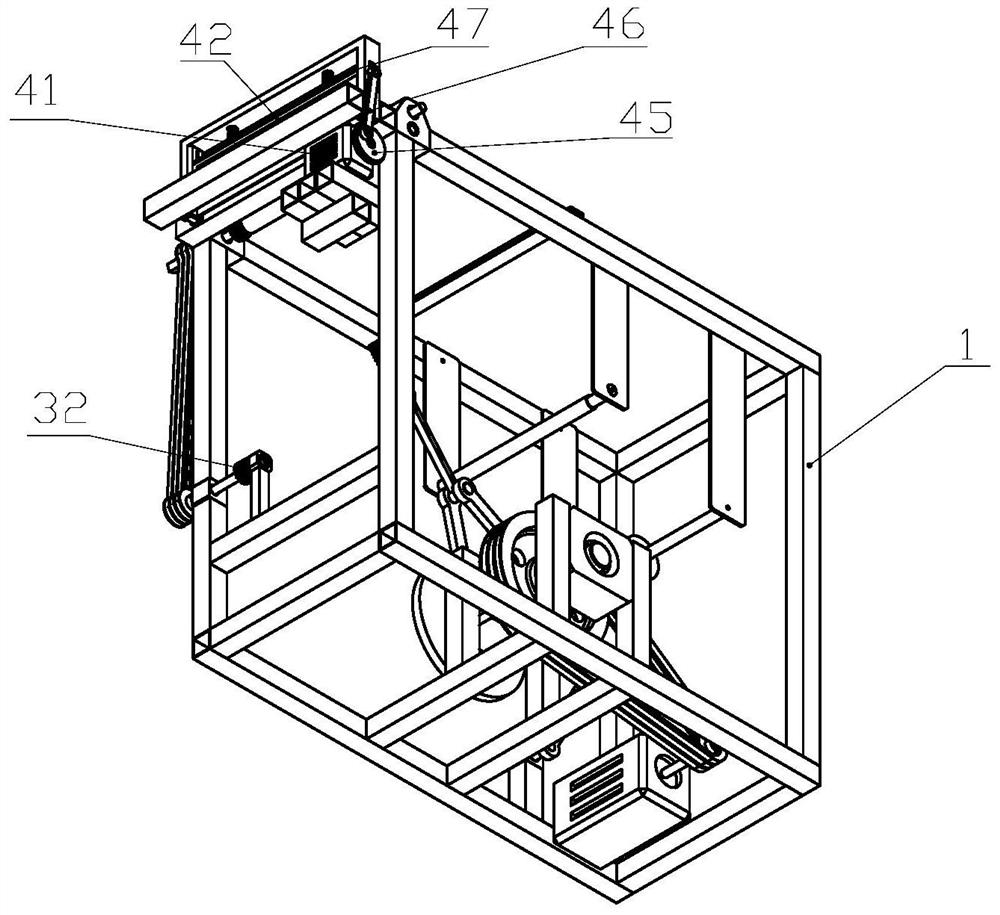

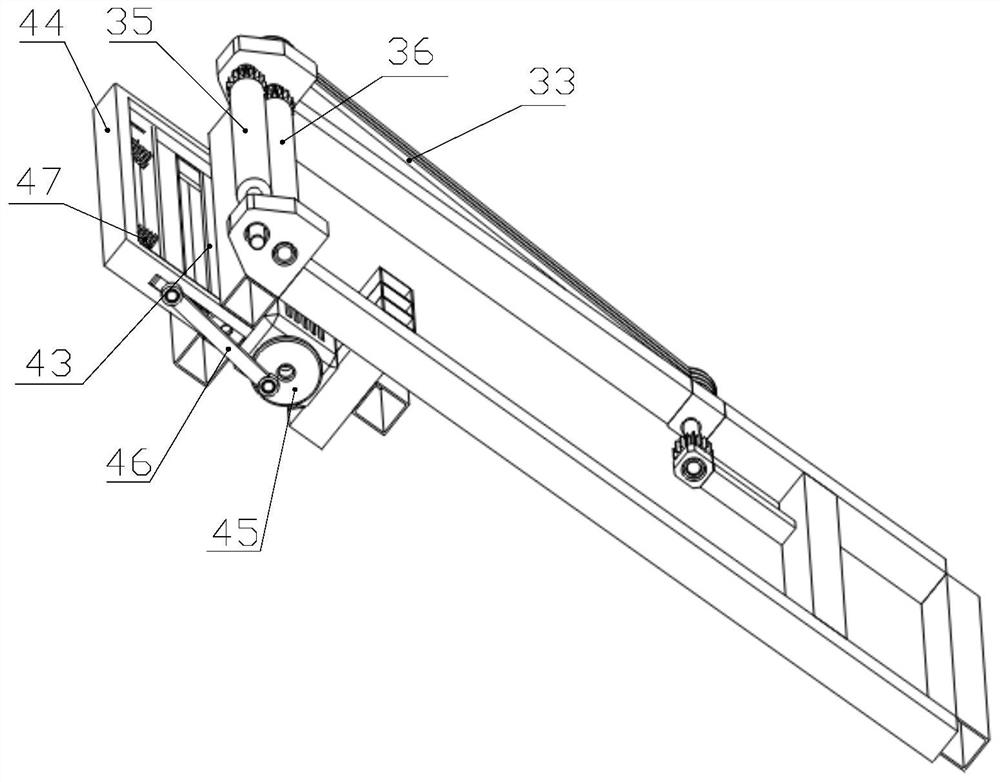

[0023] Specific implementation mode one: combine Figure 1~5 Describe this embodiment, a kind of plastic film slicer, it comprises frame 1 and the driving component 2 that is installed on frame 1, transmission component 3 and cutting component 4, wherein said transmission component 3 comprises rack bar 31, cylinder The gear 32, the first belt transmission assembly 33, the gear pair 34, the upper roller shaft 35 and the lower roller shaft 36, the rack bar 31 is controlled by the driving assembly 2 to realize the reciprocating motion with a closed curve trajectory, and the rack bar 31 drives the cylindrical gear 32 to perform intermittent rotation, the cylindrical gear 32 and the upper roller shaft 35 are connected through the first belt transmission assembly 33, and the upper roller shaft 35 and the lower roller shaft 36 are mutually Arranged flat and connected by a gear pair 34; the cutting assembly 4 is located behind the transmission assembly 3 and the cutting assembly 4 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com