A kind of production technology of concrete pipe pile

A technology of concrete pipe piles and production technology, which is applied in the direction of clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve the problems of poor concrete preparation quality, and achieve the effects of avoiding heating quality, improving preparation quality, and rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

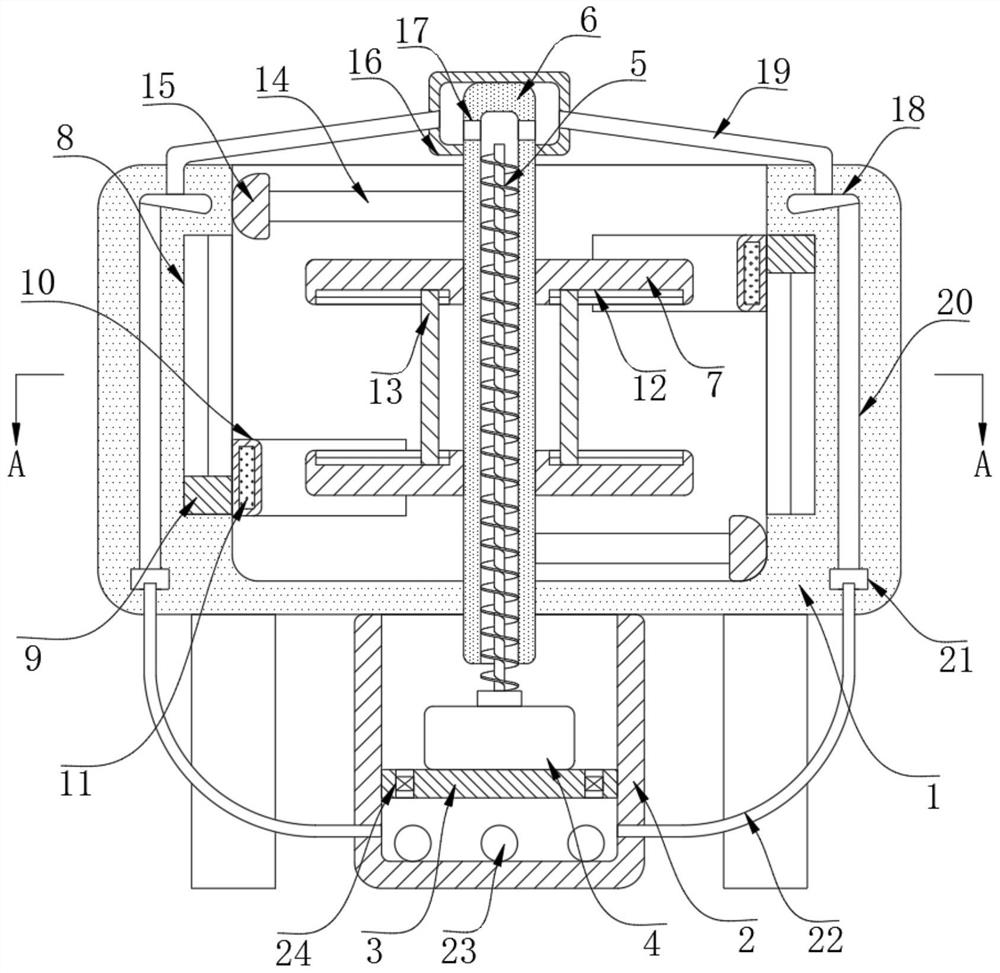

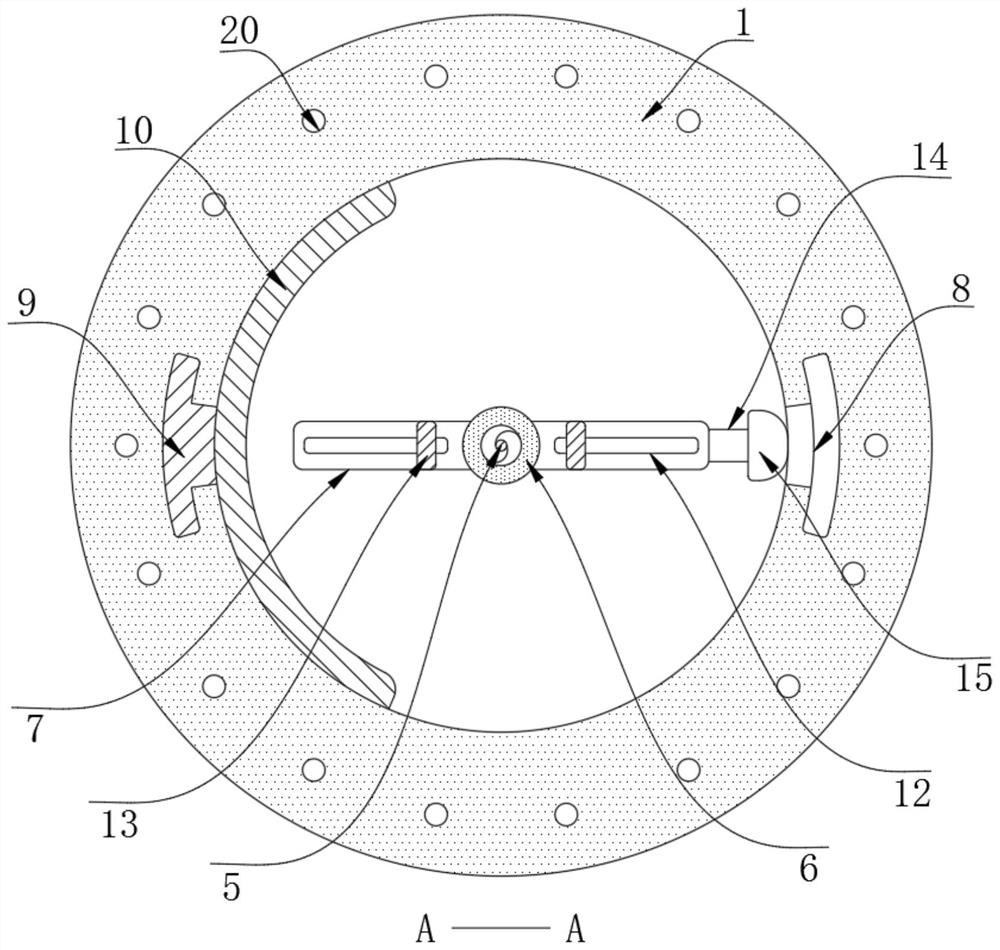

[0022] refer to Figure 1-2 , a production process for concrete pipe piles, mainly comprising the following processing steps:

[0023] S1. Feeding: add multiple raw materials into the mixing tank 1, avoid concentrated accumulation of the same raw materials when feeding, and alternately add multiple raw materials to form initial mixing;

[0024] S2. Liquid injection heating: add evaporating liquid to the inside of the water tank 2, and start the heating rod 23 to heat the evaporating liquid and preheat the evaporating liquid, so as to achieve a faster heating state;

[0025] S3. Stirring: Start the motor 4 to drive the auger shaft 5 and the stirring rod 6 to rotate, so that the stirring blade 7 rotates to mix and stir the raw materials, and at the same time, the auger shaft 5 transports the heated evaporated liquid to the heating hole 20 to realize The comprehensive heating treatment of the mixing tank 1 improves the overall mixing efficiency and quality. At the same time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com