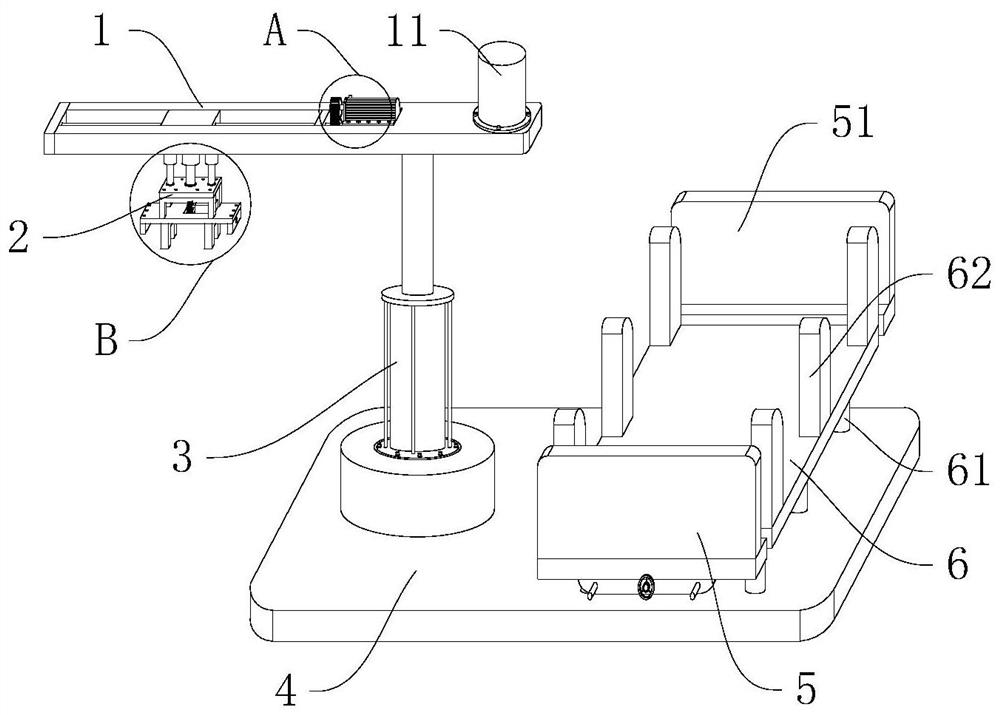

Steel part stacking and sorting device

A sorting device and stacking technology, which is applied in the field of stacking and sorting devices for steel parts, can solve the problems of affecting the sorting effect, consuming manpower, and personnel injury, and achieve the effect of improving the sorting effect, reducing labor intensity, and realizing positioning and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

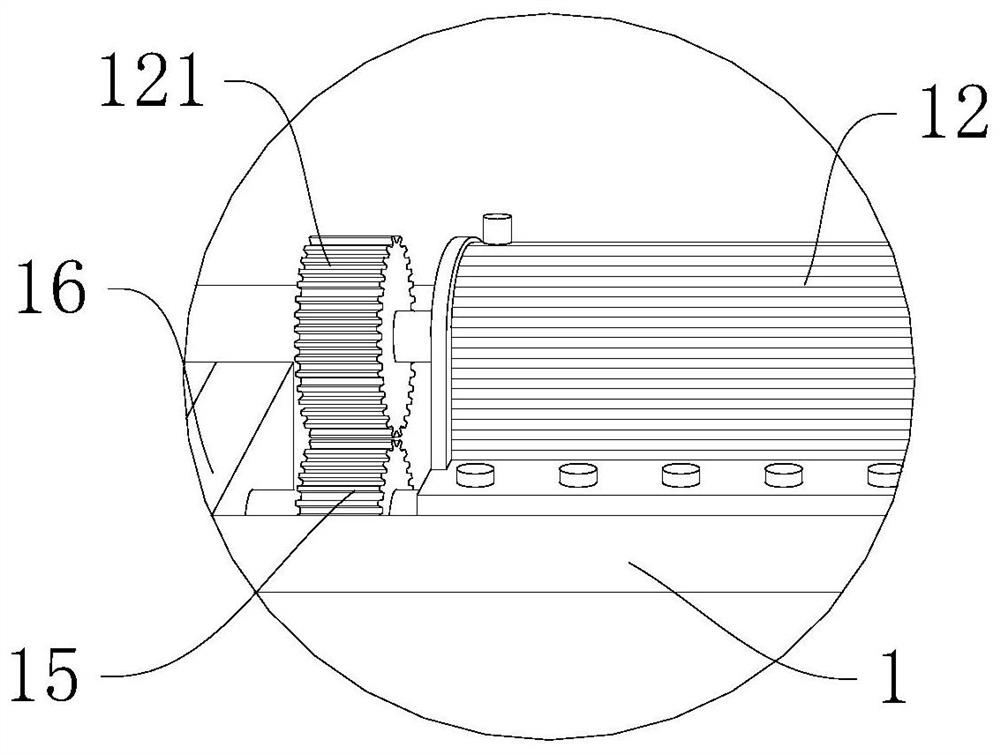

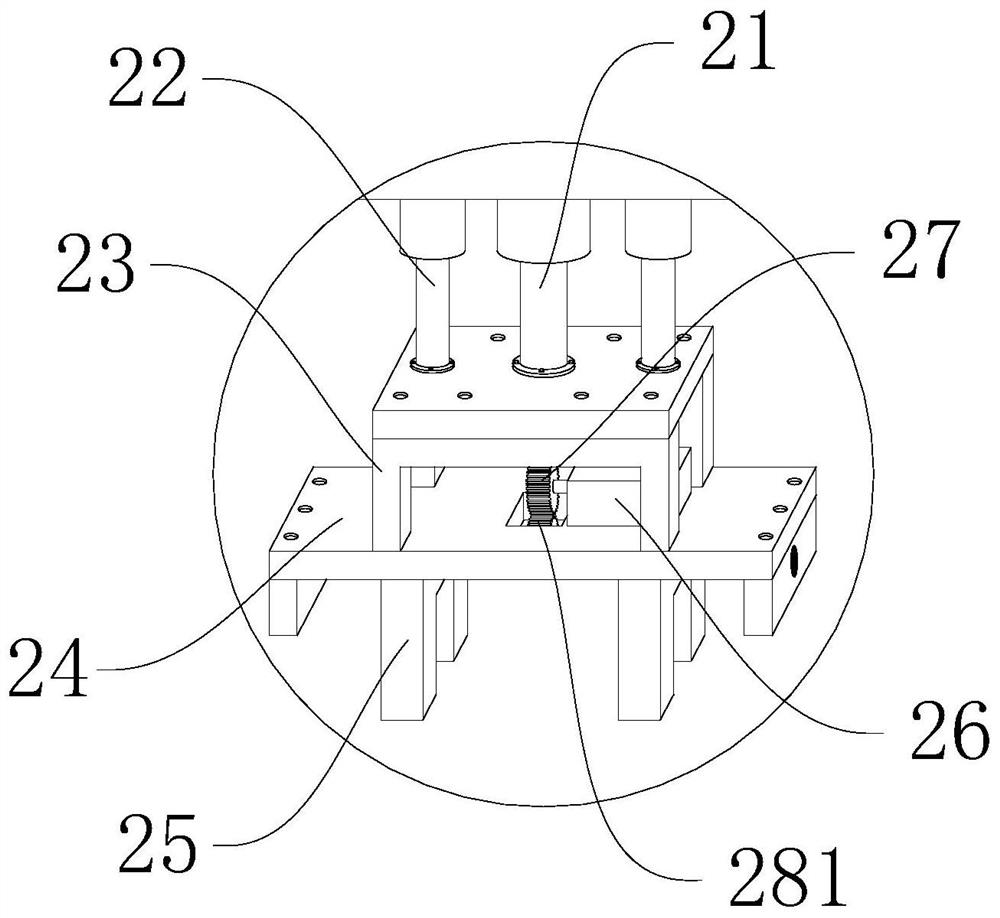

[0042] Specific embodiments: when in use, firstly insert the lower side parallel part of the I-shaped fixed block 58 fixed at the lower end of the stacking plate 6 into the inverted T-shaped groove 55 on the fixed seat 56, then pass the latch 57 through the fixed seat 56 and Through the parallel part of the lower side of the I-shaped fixed block 58, the fixed seat 56 is quickly installed on the lower end of the palletizing plate 6, thereby realizing the rapid assembly of the leveling component 5, and then the assembled palletizing plate 6 is transported by a forklift, and then Place the stacking plate 6 on the upper end of the base plate 4, and insert the positioning support rod 61 into the positioning hole 41 on the base plate 4 to realize the positioning and installation of the palletizing plate 6, and then connect the lifting drive device 3, the first drive Motor 12, electric push rod 21, the second drive motor 26 and the circuit of the third drive motor 34, then start the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com