Pull lifting platform for railway rescue

A technology of traction lifting and platform, which is applied in the direction of lifting frames, railway car body parts, railway auxiliary equipment, etc., and can solve problems such as poor rescue conditions, short skylight period, and inconvenience of normal railway running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

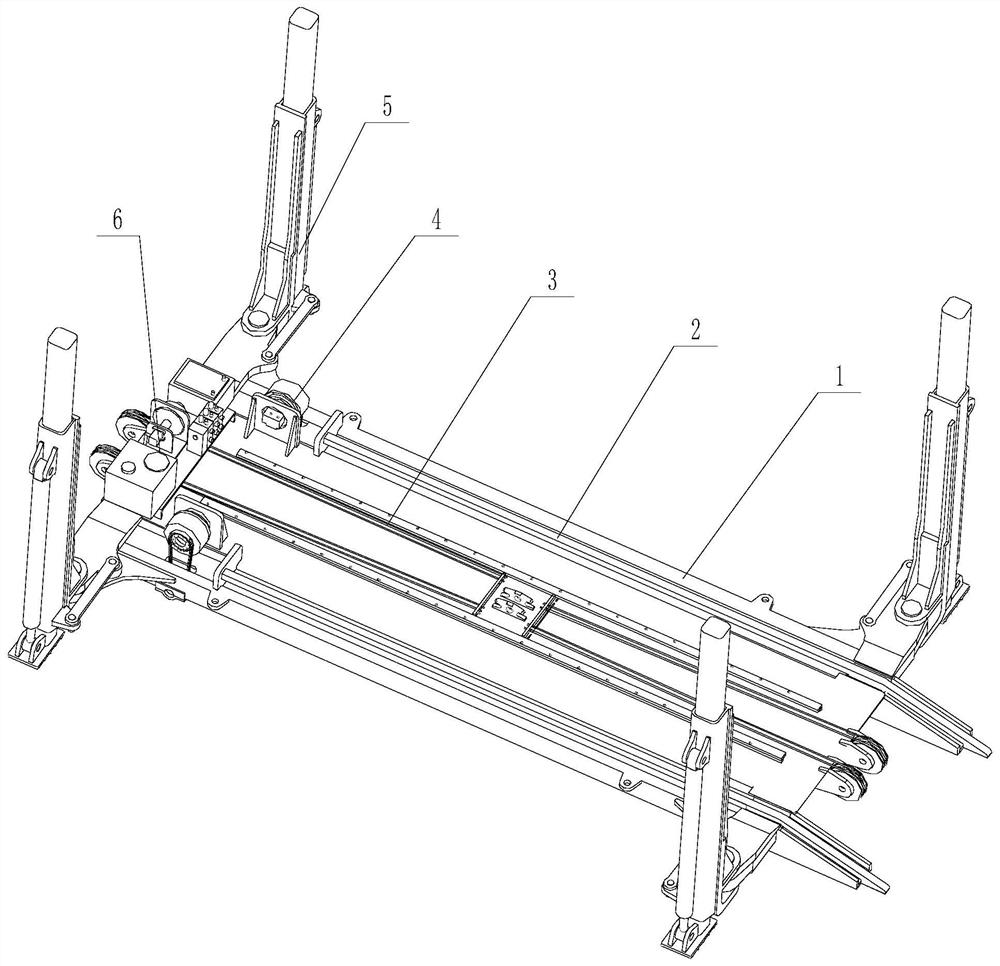

[0041] like figure 1 As shown, a traction lifting platform for railway rescue includes a platform 1, and the platform 1 is provided with a track 2, a traction mechanism 3, a walking device 4, a folding outrigger lifting mechanism 5 and a control system 6, and the control system 6 They are respectively connected with the traction mechanism 3, the running gear 4 and the folding outrigger lifting mechanism 5.

Embodiment 2

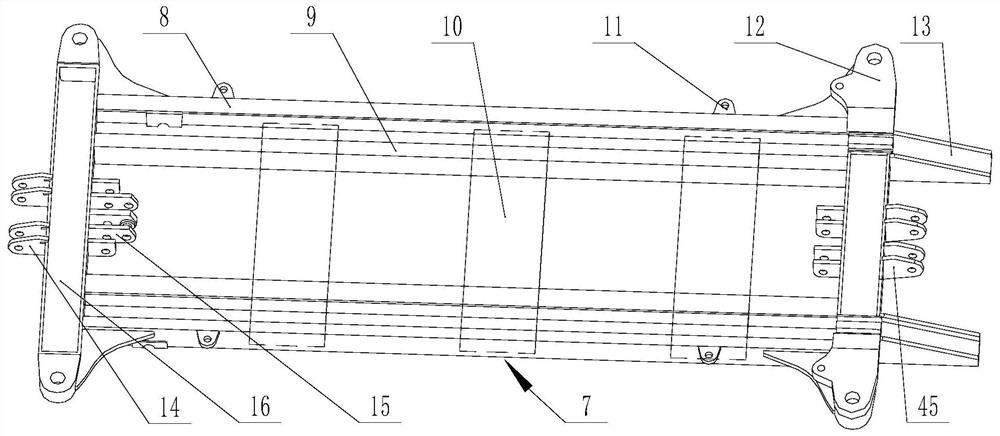

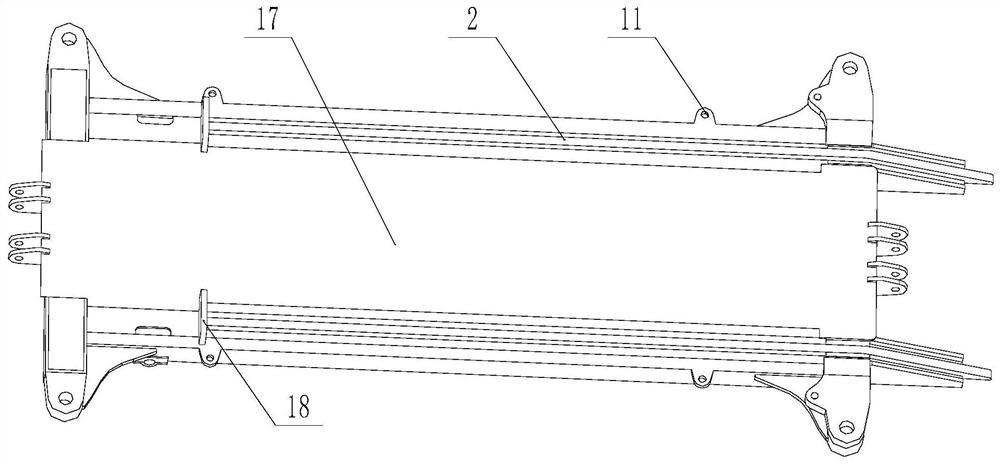

[0043] A traction lifting platform for railway rescue, such as figure 2 and image 3 As shown, the platform 1 includes a frame main plate 7, and the frame main plate 7 includes a rectangular tube A8, a rectangular tube B9, a bottom plate 10 and a channel steel 16, and the rectangular tube A8, the rectangular tube B9, the bottom plate 10 and the channel steel 16 form a frame structure, which has Sufficient bearing capacity, the frame body plate 7 is welded with a leg mount 12 , a top plate 17 , a pulley seat and an oil cylinder seat 15 .

[0044] Platform 1 is the installation platform for other equipment and also the carrier for transporting rescue equipment. Its width is less than the maximum width of 3000mm of the flatbed truck, and its length is in accordance with the needs of transporting rescue equipment. The track 2 is welded on the platform 1, and the width of the track 2 is consistent with that of the railway track.

[0045] like Figure 4-8As shown, the traction m...

Embodiment 3

[0053] A traction lifting platform for railway rescue, the locking mechanism includes a locking rod 44, and a locking rod mounting seat 11 cooperating with the locking rod 44 is also provided on the main body plate 7 of the frame. like Figure 13 As shown, the folding leg lifting mechanism 5 performs folding and lifting actions, and is symmetrically installed on the front and rear parts of the platform 1 through the pin shaft 43 and the locking rod 44. Internal sliding; the outrigger frame 41 can be opened or folded as required, and locked with the locking lever 44 .

[0054] The locking type of the folding outrigger lifting mechanism 5 is a rigid pull rod, which will Figure 15 The pin shafts at both ends of the locking rod 44 shown are inserted into the mounting holes of the locking rod mounting base 11 for locking. The structure is simple, but manual installation is required. Other parts are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com