Vortex air floatation device

A vortex air flotation and air intake hood technology, which is used in flotation water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. problem, to achieve the effect of small bubble diameter, good air flotation effect, and slow floating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

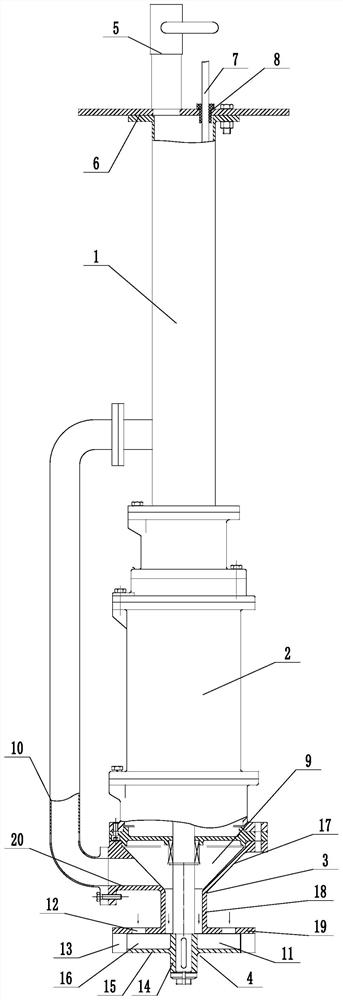

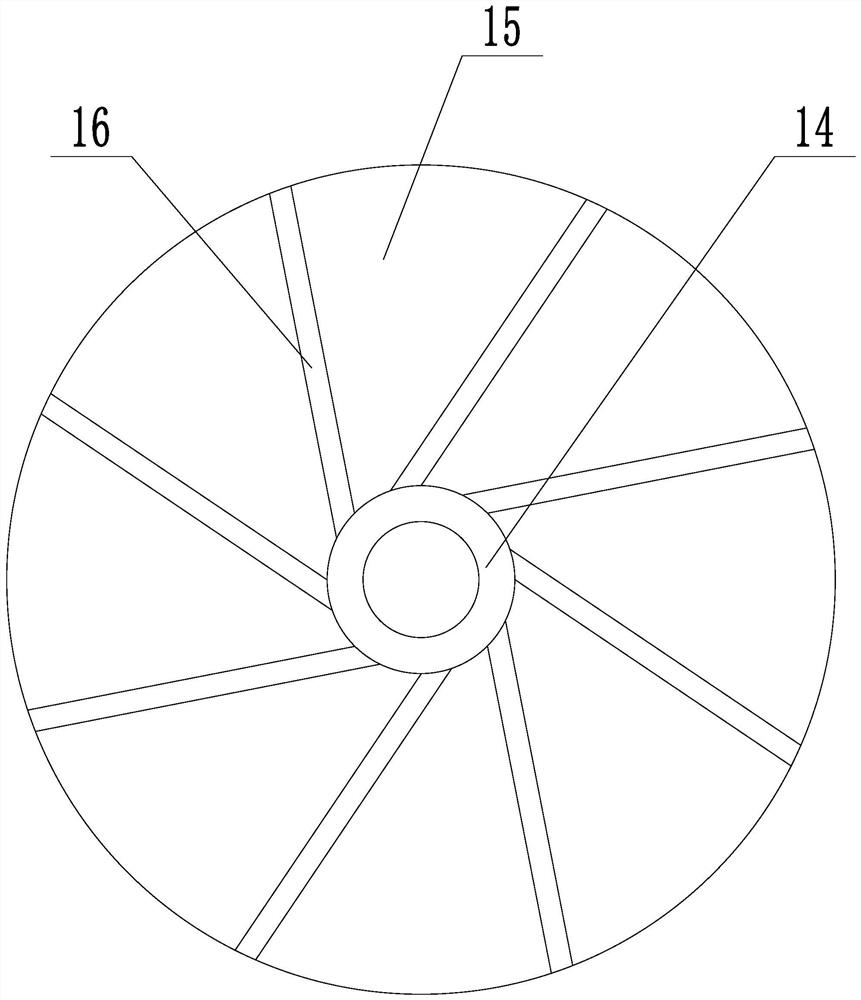

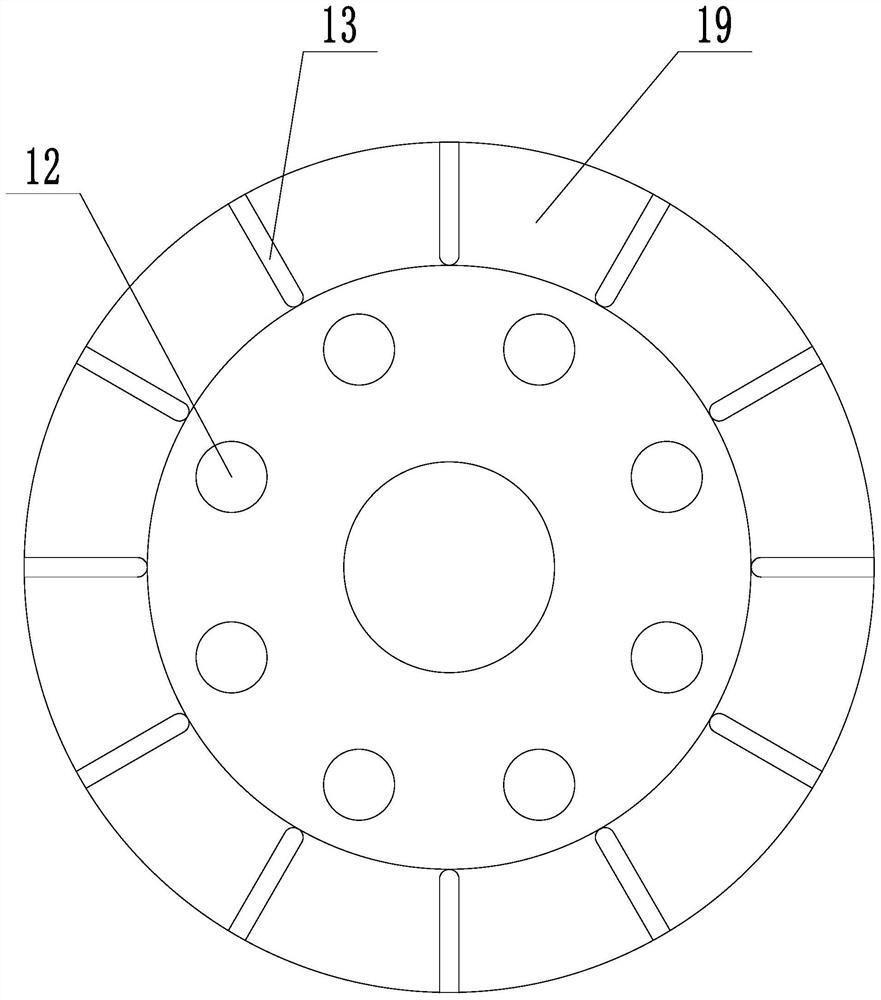

[0026] Embodiment 1: A kind of vortex air flotation device (see attached figure 1 To attach image 3 ), including installation sleeve 1, power motor 2, intake cover 3, impeller 4, the power motor is a submersible motor, the power motor is installed at the lower end of the installation sleeve, the intake cover is installed at the lower end of the power motor, and the upper end of the installation sleeve is installed with air volume Regulating valve 5, the upper end of the installation sleeve is tightly connected to the support plate 6, the support plate is provided with an air inlet hole and a cable installation hole, the air volume regulating valve is installed on the air inlet hole, and the cable 7 is tightly connected in the cable installation hole. A sealing sleeve 8 is installed between the cable and the cable installation hole. The upper end of the installation sleeve is placed above the water surface, and the impeller is placed in the water. The air intake cover is pro...

Embodiment 2

[0029] Embodiment 2: A kind of vortex air flotation device (see attached Figure 4 To attach Figure 6), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, a rotating shaft 21 is installed between two adjacent fixed blades on the intake cover, and three driving blades 22 are evenly distributed on the outer wall of the rotating shaft, and the driving blades are installed on The outer edge of the impeller cavity. Several through holes 23 are arranged on the driving blade. The through holes can not only shear the air bubbles, but also help reduce the resistance to the outward flow of the gas-liquid mixture. A shaking plate 24 is installed between two adjacent rotating blades on the cover plate, and a number of shear holes 25 are densely covered on the shaking plate. A pair of splints 26 are arranged at both ends of the shaking plate on the cover plate, and both ends of the shaking plate are installed on the two splints. Between, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com