Fixing device used for gas pipeline along-bridge laying

A technology for fixing devices and gas pipelines, applied in the direction of cleaning methods using gas flow, pipeline supports, pipeline protection, etc., can solve the problems of different pipeline sizes, the influence of gas pipeline fixing, etc., and achieve the effect of increasing the flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

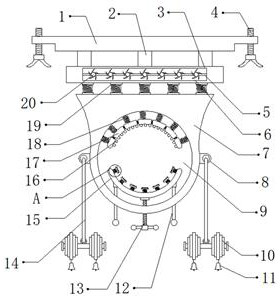

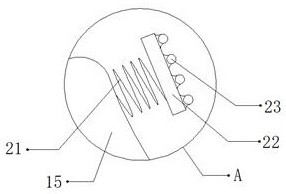

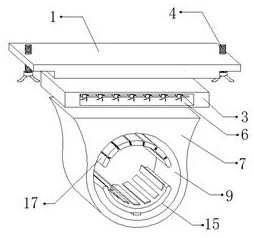

[0029] refer to Figure 1-3 , a fixing device for laying a gas pipeline with a bridge, comprising a mounting base 1, a plurality of fixed shafts 2 are connected to the bottom outer wall of the mounting base 1 through bolts, and a fixed plate 3 is connected to the bottom outer wall of the fixed shaft 2 through bolts, The bottom outer wall of the fixed plate 3 is connected with a plurality of second springs 19 by bolts, and the bottom outer wall of the second spring 19 is connected with a support plate 7 by bolts, and one side outer wall of the support plate 7 is provided with a fixed opening 9, and the fixed opening 9 A plurality of first springs 18 are connected to the top inner wall by bolts, and a clamping mechanism 17 is connected to one side of the outer wall of the first springs 18 by bolts. The clamping mechanism 17 is composed of multiple clamping blocks, and two adjacent clamping blocks The blocks are connected by elastic parts, and the bottom outer wall of the clampin...

Embodiment 2

[0038] refer to Figure 4 , a fixing device for laying gas pipelines with bridges. Compared with Embodiment 1, the outer walls of both sides of the support plate 7 are connected with arc-shaped plates 24 by bolts, and the bottom outer walls of the arc-shaped plates 24 are set There are a plurality of buffer pads 25 , the bottom outer wall of the buffer pad 25 is provided with a pressing plate 26 , and the bottom outer wall of the pressing plate 26 is provided with a brush plate 27 .

[0039] Working principle: When in use, the device is fixed on the bridge through the mounting base 1 and the fixing bolt 4. When the gas pipeline needs to be fixed, the gas pipeline is inserted inside the fixed port, and the clamping mechanism 17 and the first spring 18 are used to fix the device on the bridge. , The third spring 21 and the splint 15 can effectively fix the gas pipeline according to the size of the gas pipeline, and turn the stop bolt 13 to fix the gas pipeline. The friction for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com