Solid waste incineration device based on environmental protection technology

A solid waste and incineration device technology, applied in incinerators, combustion types, combustion methods, etc., can solve problems such as environmental pollution, human injury, and large smoke, and achieve the effect of improving incineration effect, avoiding impact, and effectively incinerating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

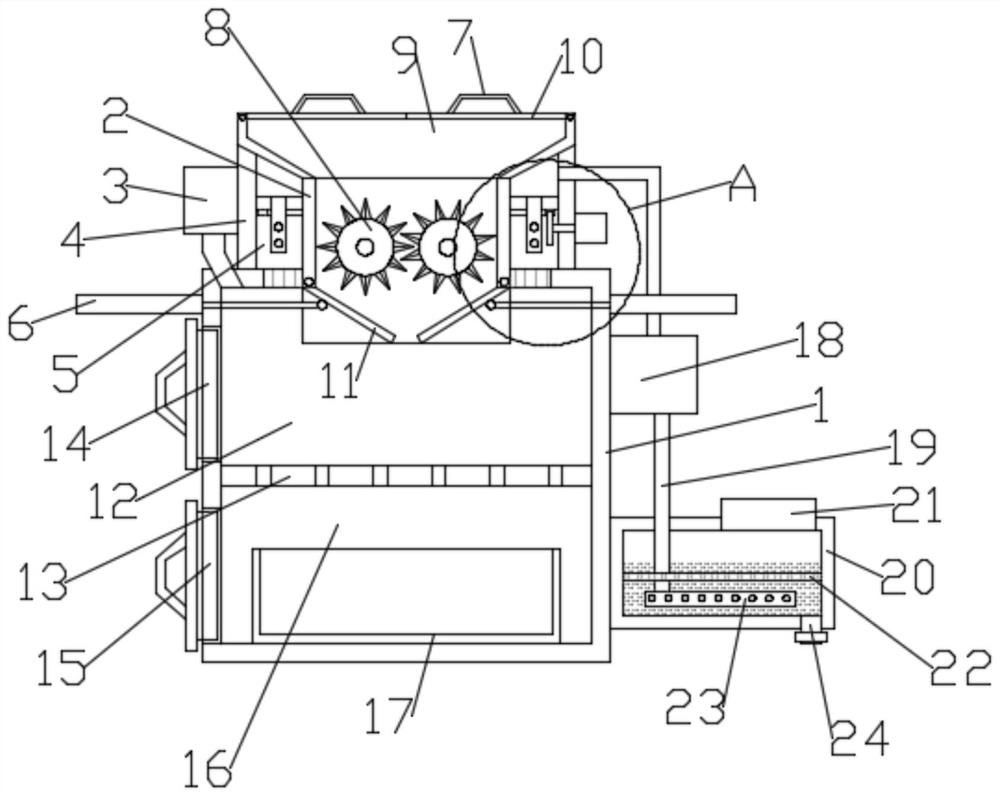

[0024] Such as figure 1 As shown, in the embodiment provided by the present invention, a solid waste incineration device based on environmental protection technology includes an incineration box 1, and the inner cavity of the incineration box 1 is divided into an incineration cavity 12 by an incineration plate 13 provided. And the upper and lower chambers of the collection chamber 16, and the collection chamber 16 is provided with a collection frame 17 directly below the incineration plate 13;

[0025] The upper side of the incineration box 1 is provided with a first window cover 14 corresponding to the incineration cavity 12; the lower side of the incineration box 1 is provided with a second window cover corresponding to the collection cavity 16 Window cover 15;

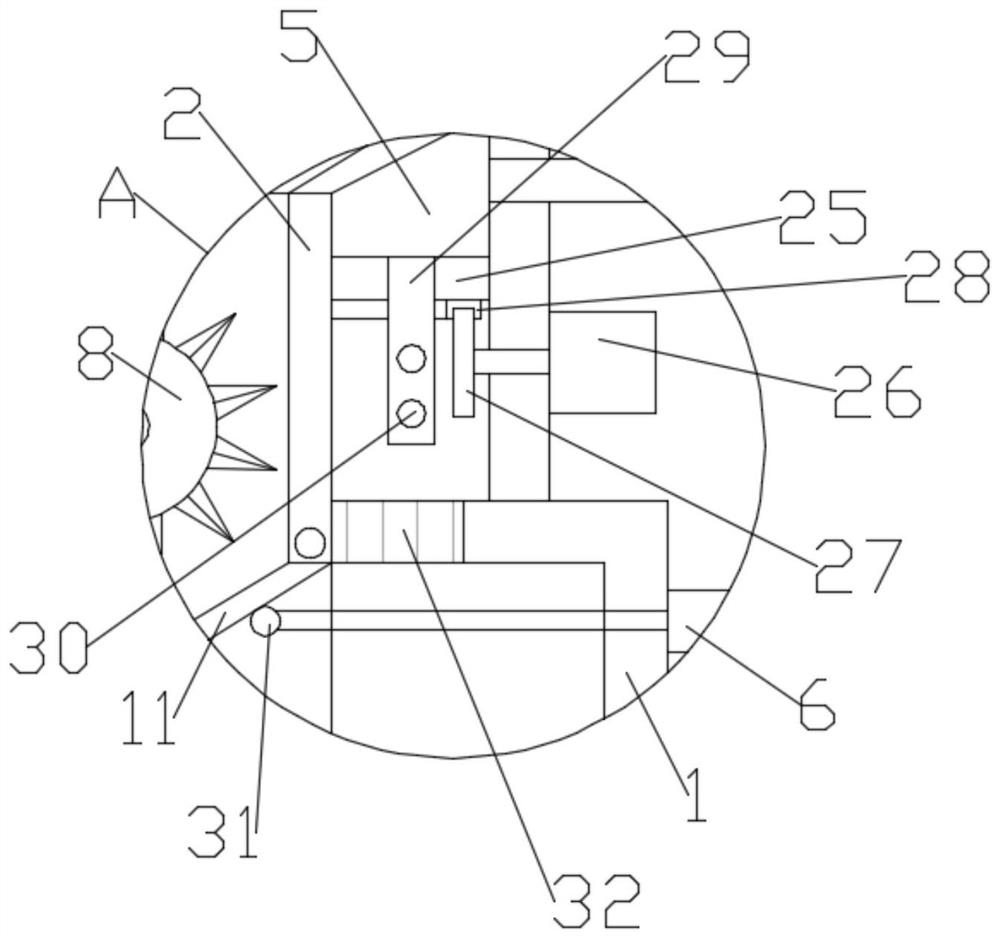

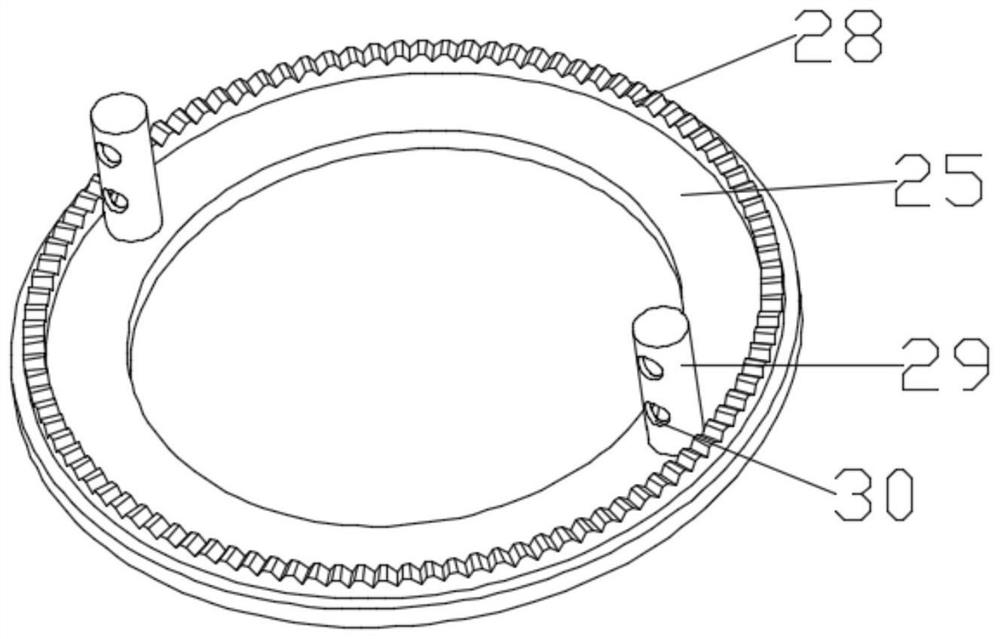

[0026] Further, the top fixing frame of the incineration box 1 is provided with a crushing drum 2, and the top of the crushing drum 2 is provided with a dropping funnel 9. The top of the dropping funnel 9 is opened and c...

Embodiment 2

[0031] Such as Figure 1-3 As shown, different from Embodiment 1, in the embodiment provided by the present invention, the air purification assembly includes an air purification box 20 fixedly installed on the outer wall of the incineration box body 1, and the top of the air purification box 20 has exhaust Port 21, the inner cavity of the air purification box 20 is fixed with an air distribution ring tube 23, and the air inlet end of the air distribution ring tube 23 communicates with the upper cavity of the insulation ring cavity 5 through the air outlet pipe 19, wherein the first 2. The air pump 18 is fixedly installed on the air outlet pipe 19;

[0032] Further, in the embodiment provided by the present invention, the air purification box 20 is also provided with a dispersing mesh plate 22 located above the air distribution ring pipe 23, which can prevent upward escaping in the air purification box 20 The gas is broken up to make it more fully react with the acid and alkali s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com