Preparation method of reconstituted tobacco for increasing content of dihydroactinidiolide

A technology of reconstituted tobacco leaf and weight ratio, which is applied in the direction of preparing tobacco, tobacco, and treating tobacco, etc., which can solve the problems of long natural degradation period, many influencing factors, and difficult control of the process, and achieve the increase of dihydroactinolactone content and improvement Color, effects that enhance sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

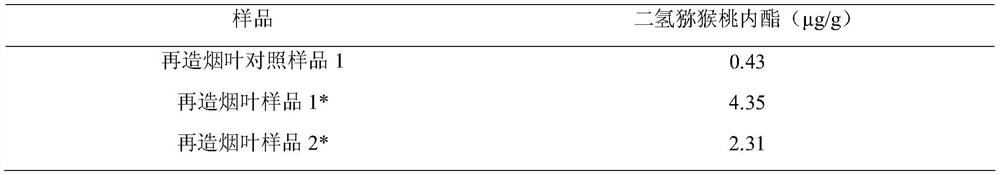

Examples

Embodiment 1

[0041] Weigh 0.3g of 30wt% β-carotene oil suspension, add 1g of emulsifier: Tween 80 for grinding, and then add 8.9g of distilled water to prepare to obtain a water-soluble β-carotene with a mass fraction of β-carotene of 0.88% white.

[0042] 1g of water-soluble beta-carotene, 0.1g of variable valence metal salt: ferrous sulfate and 8g of hydrogen peroxide (30% by mass) were added to 100g of concentrated solution successively, and the stirring speed was 300 rpm at 50°C. After stirring and reacting under different conditions for 30 minutes, a coating liquid sample 1# was prepared. The concentrated solution is the concentrated solution obtained after the tobacco extract is concentrated, and the density of the concentrated solution is 1.18 g / cm 3 .

[0043] The above-mentioned coating solution sample 1# was coated on the reconstituted tobacco leaf substrate, and the coating rate was 36%. After drying at 105°C for 5 minutes, it was cut to obtain the desired reconstituted tobac...

Embodiment 2

[0045] Weigh 0.6 g of 30 wt% β-carotene oil suspension, add 2 g of emulsifier (polyglycerol fatty acid ester: Tween 80 = 1:1) for grinding, and then add 7.8 g of distilled water to prepare to obtain β-carotene. The mass fraction is 1.73% water-soluble beta-carotene.

[0046] Add 0.4g water-soluble β-carotene, 0.2g variable valence metal salt: copper sulfate and 8g hydrogen peroxide (mass percentage concentration is 27%) to 100g concentrated solution successively, at 60 ° C, the stirring speed is 400 rpm / After stirring and reacting under different conditions for 40 minutes, a coating liquid sample 2# was prepared. The concentrated solution is the concentrated solution obtained after the tobacco extract is concentrated, and the density of the concentrated solution is 1.18 g / cm 3 .

[0047] The above-mentioned coating solution sample 2# was coated on the reconstituted tobacco leaf substrate, and the coating rate was 36%. After drying at 105°C for 5 minutes, it was cut to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com