Noise-reducing food processor

A food processing machine and noise reduction technology, which is applied in the field of food processing, can solve problems such as loud noise and affecting user experience, and achieve the effects of reducing noise, improving crushing effect, and extending the transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

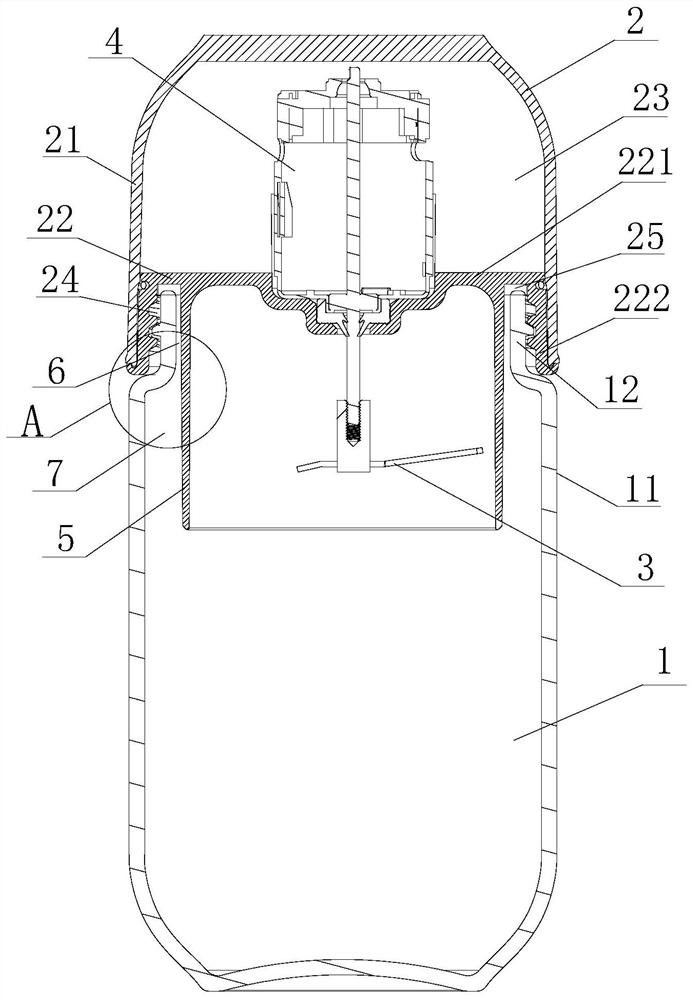

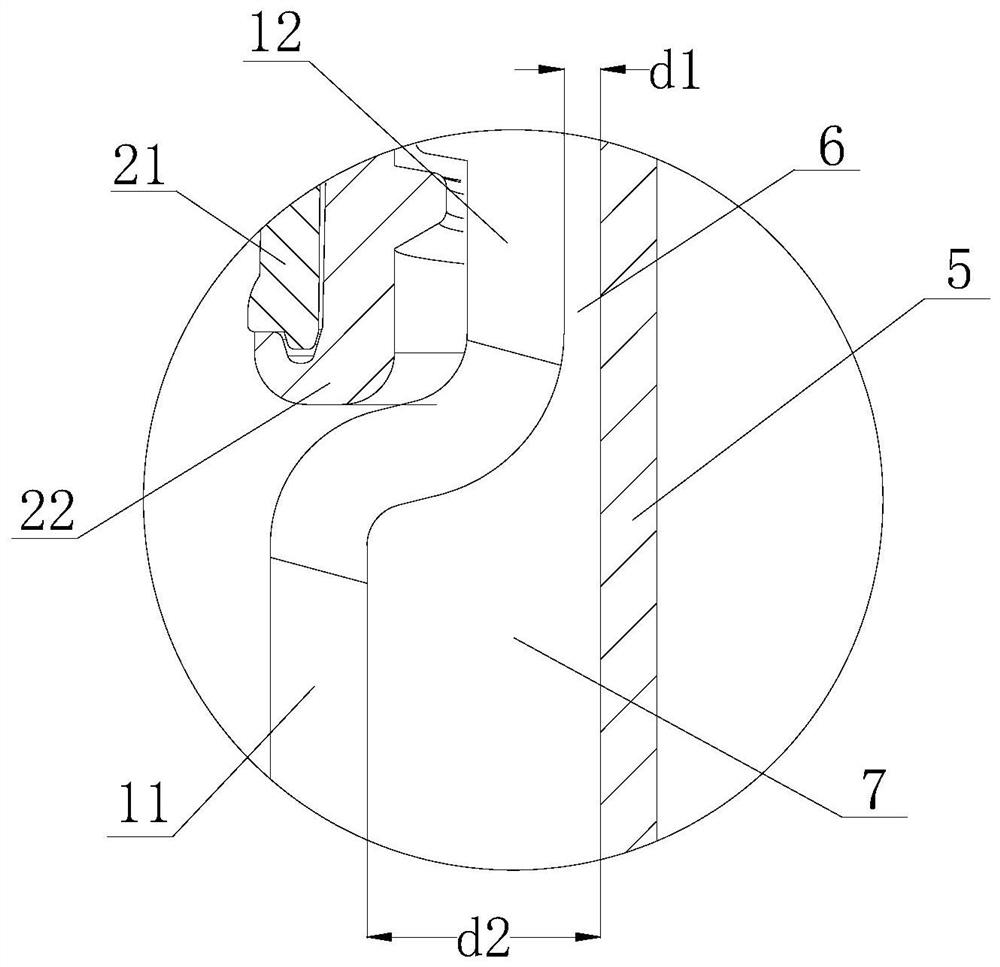

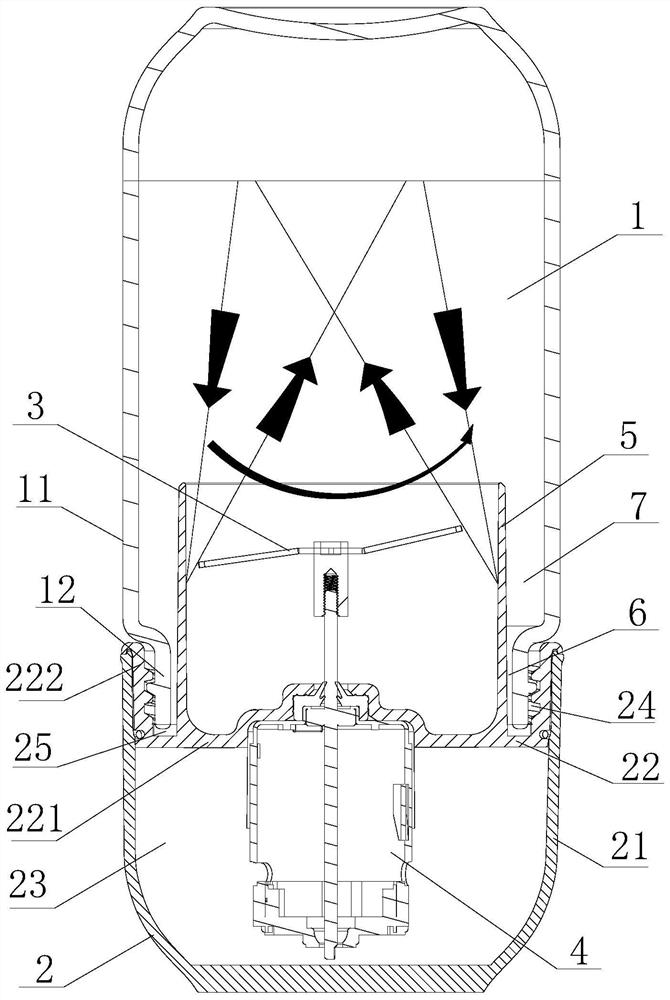

[0024] like Figure 1-Figure 3 As shown, the present invention provides a noise-reducing food processor, comprising a cup body 1 and a cup cover 2, the cup body 1 includes a cup body 11 and a cup mouth 12, and the cup lid 2 is detachably installed at the cup mouth 12, and the cup mouth The inner diameter of 12 shrinks inwardly relative to the inner diameter of the cup body 11, that is, the cup mouth 12 is a shrinking structure, specifically, as figure 1 As shown, the outside of the cup opening 12 is provided with external threads, and the inside of the cup cover 2 is provided with internal threads. The cup cover 2 is installed to the cup opening 12 through the cooperation of the internal and external threads. When the outer side of the mouth 12 is tightened, the distance between the outer side wall of the cup cover 2 and the outer side wall of the cup body 11 is reduced, which is not only convenient for taking and placing but also has a beautiful appearance.

[0025] The bott...

Embodiment 2

[0037] The difference between this embodiment and the first embodiment is that a sunken protruding portion is provided at the bottom of the lower cover, and at least part of the motor is installed in the protruding portion.

[0038] In this example, if Figure 4 , Figure 5 As shown, the present invention provides a noise-reducing food processor, comprising a cup body 1 and a cup cover 2, the cup cover 2 includes an upper cover body 21 and a lower cover body 22, and the lower cover body 22 includes a cup cover bottom wall 221 and a set The surrounding edge 222 around the bottom wall 221 of the cup cover extends downwards. The bottom wall 221 of the cup cover is provided with a sunken protrusion 223. The upper cover body 21 includes a top wall of the cup cover and a side wall of the cup cover. The side wall of the cover is set on the outside of the surrounding edge 222 so that the upper cover body 21 and the lower cover body 22 form an installation cavity 23, the installation ...

Embodiment 3

[0042] The difference between this embodiment and the second embodiment is that the sound insulation cover is arranged on the bottom wall of the protrusion, and the outer diameter of the sound insulation cover is smaller than the outer diameter of the protrusion, that is, the sound insulation cover forms a constricted structure relative to the protrusion.

[0043] In this example, if Image 6 As shown, the present invention provides a noise-reducing food processor, comprising a cup body 1 and a cup cover 2, the cup cover 2 includes an upper cover body 21 and a lower cover body 22, and the lower cover body 22 includes a cup cover bottom wall 221 and a set The surrounding edge 222 around the bottom wall 221 of the cup cover extends downwards. The bottom wall 221 of the cup cover is provided with a sunken protrusion 223. The upper cover body 21 includes a top wall of the cup cover and a side wall of the cup cover. The side wall of the cover is set on the outside of the surroundin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com