Module splicing type phased array transducer

A spliced, phased array technology, applied in the direction of printed circuits, printed circuits, and electrical equipment structural components connected by non-printed electrical components, can solve the problem of positioning and replacement of a single array element that cannot be damaged, and achieve Avoid long-term high temperature damage, reduce maintenance costs and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

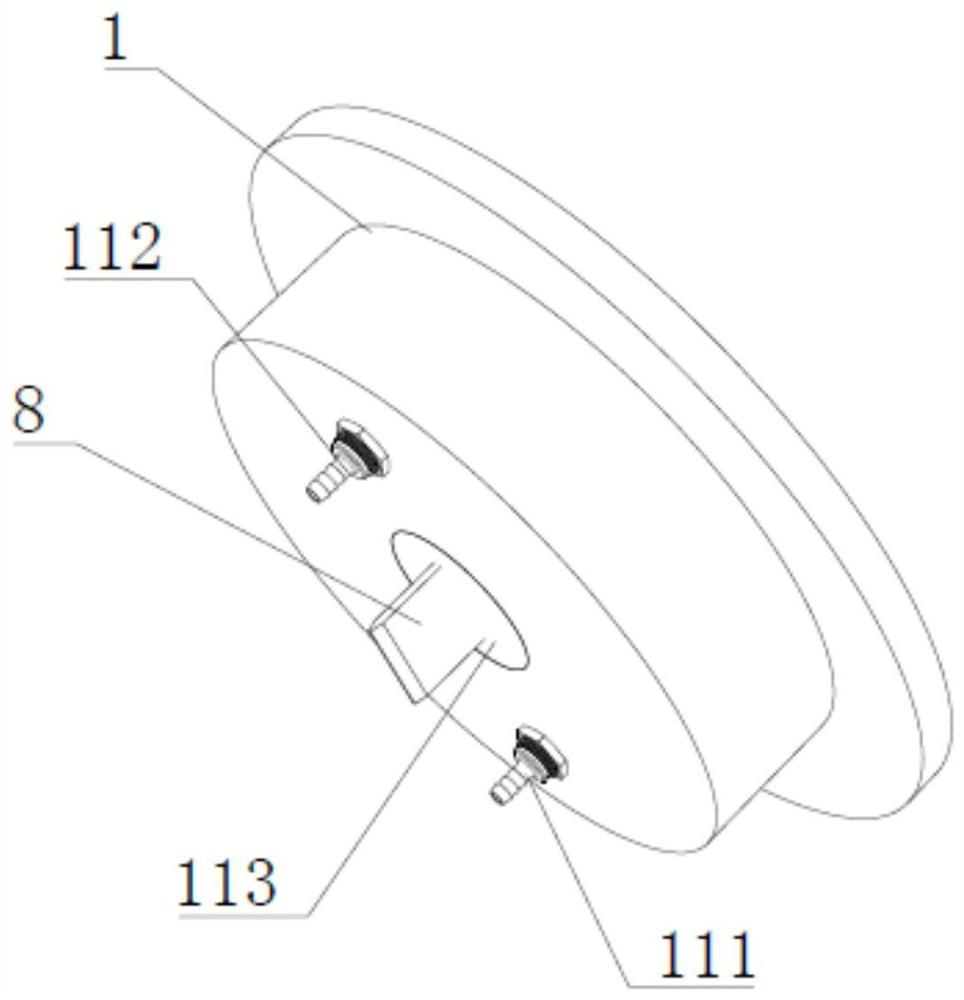

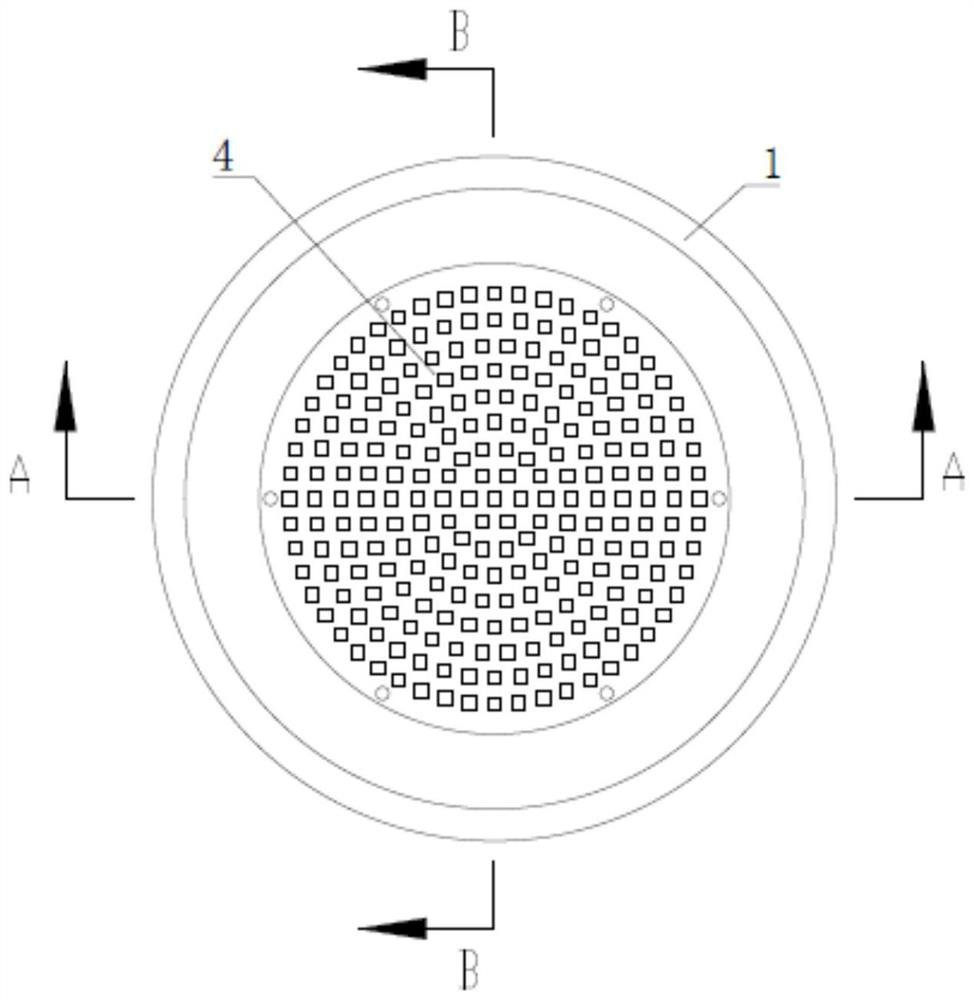

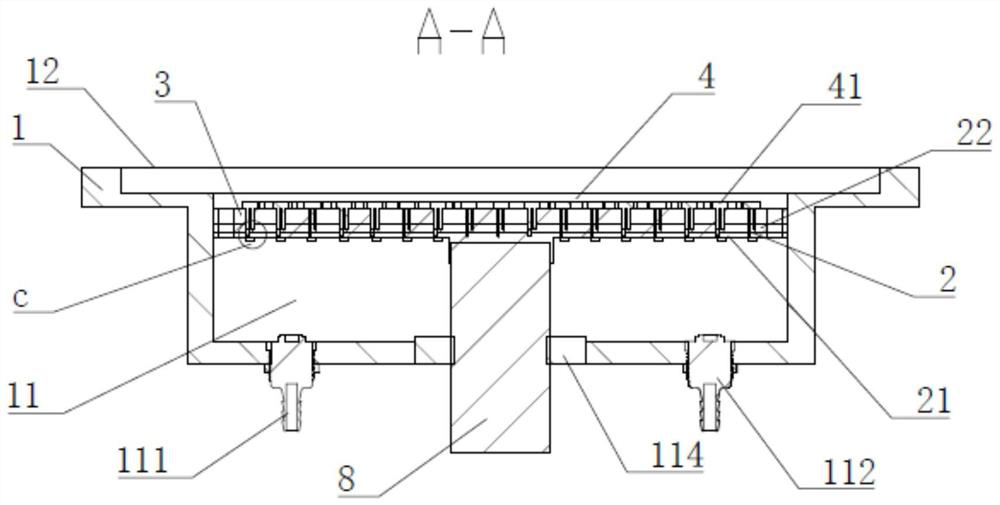

[0030] Such as Figure 1 to Figure 8 It is an embodiment of a modular splicing phased array transducer, including a housing 1, a printed circuit board 2 disposed in the housing 1, a substrate 3, a transducer array 4, and a monitoring device; the printed circuit board 2 includes The positive electrode layer 21 and the negative electrode layer 22, the substrate 3 is fixedly covered on the negative electrode layer 22 of the printed circuit board 2, the substrate 3 is provided with a plurality of through holes 31, the transducer array 4 is covered on the substrate 3, and the transduction The transducer array 4 includes a plurality of transducer array elements 41, each transducer array element 41 includes a crystal 411, a positive pole pin 412, and a negative pole pin 413, and the positive pole pin 412 is connected to the positive electrode layer 21 through the through hole 31 , the negative pin 413 is electrically connected to the negative electrode layer 22 of the printed circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com