A device and method for acquiring positioning images of basic parts in slm composite manufacturing

A positioning image and acquisition device technology, which is applied in the field of SLM composite manufacturing basic parts positioning image acquisition device, can solve the problems of increased molding time and processing cost, difficult blade part molding, long processing time, etc., and achieve light weight and stable image , the effect of convenient adjustment of focal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

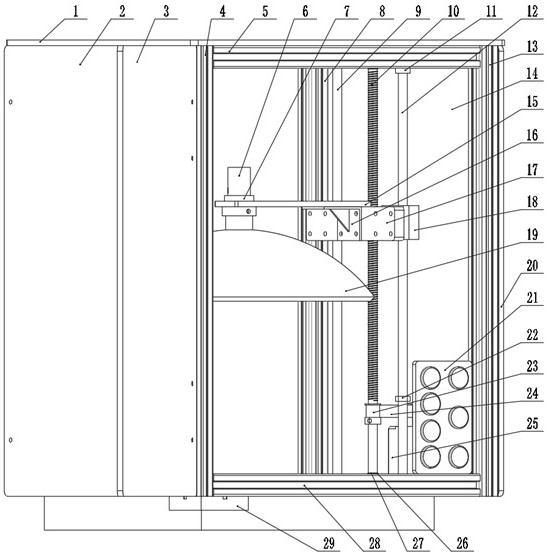

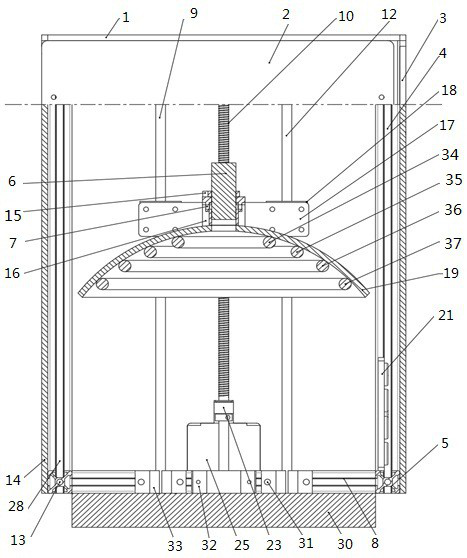

[0048] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0049] The device and method of the embodiments of the present invention are mainly proposed for the following image acquisition equipment: image acquisition to solve the problem that the positions of the SLM molding chamber, the machining base, and the substrate cannot be determined when the laser selective melting technology and traditional machining are combined to form components The device is suitable for the most widely used SLM equipment in the market with a molding size of 250*250.

[0050] An image acquisition device for positioning basic parts of SLM composite manufacturing, comprising a support module, a transmission module, an image acquisition module, an image processing module, and a control module; the support module can support the transmission module, the image acquisition module, and the control module; the transmission module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com