Spanner used in narrow space and application thereof

A wrench technology in a space, applied in a narrow space with a wrench and its application field, can solve the problems of narrow space for locking bolts in the equipment cabin, high labor intensity of the constructor, poor flexibility of the ratchet wrench, etc., and shorten the working time , average force, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

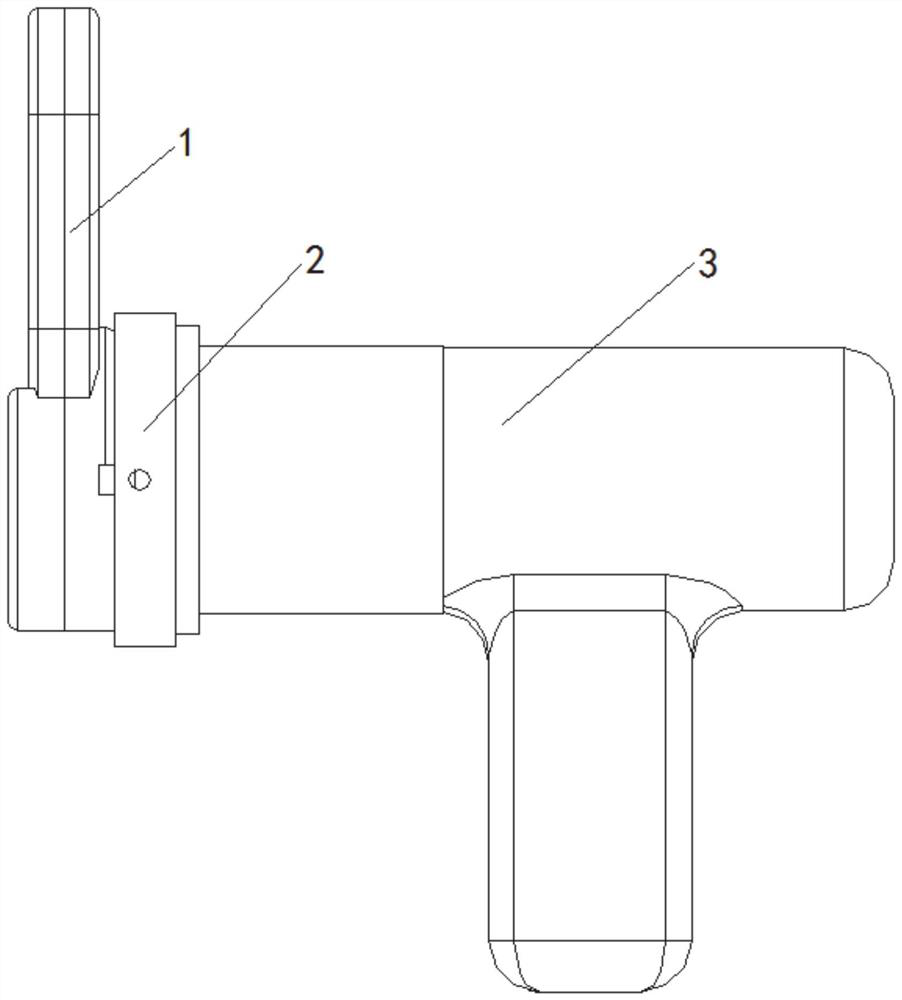

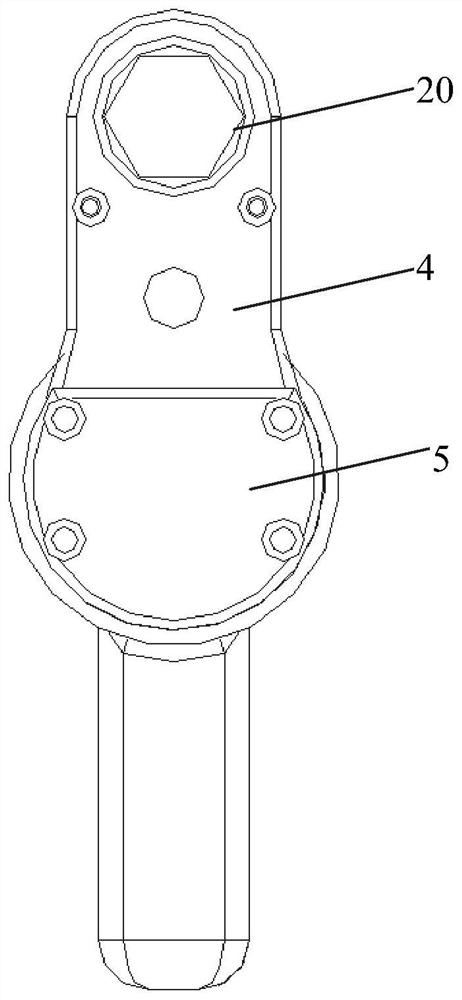

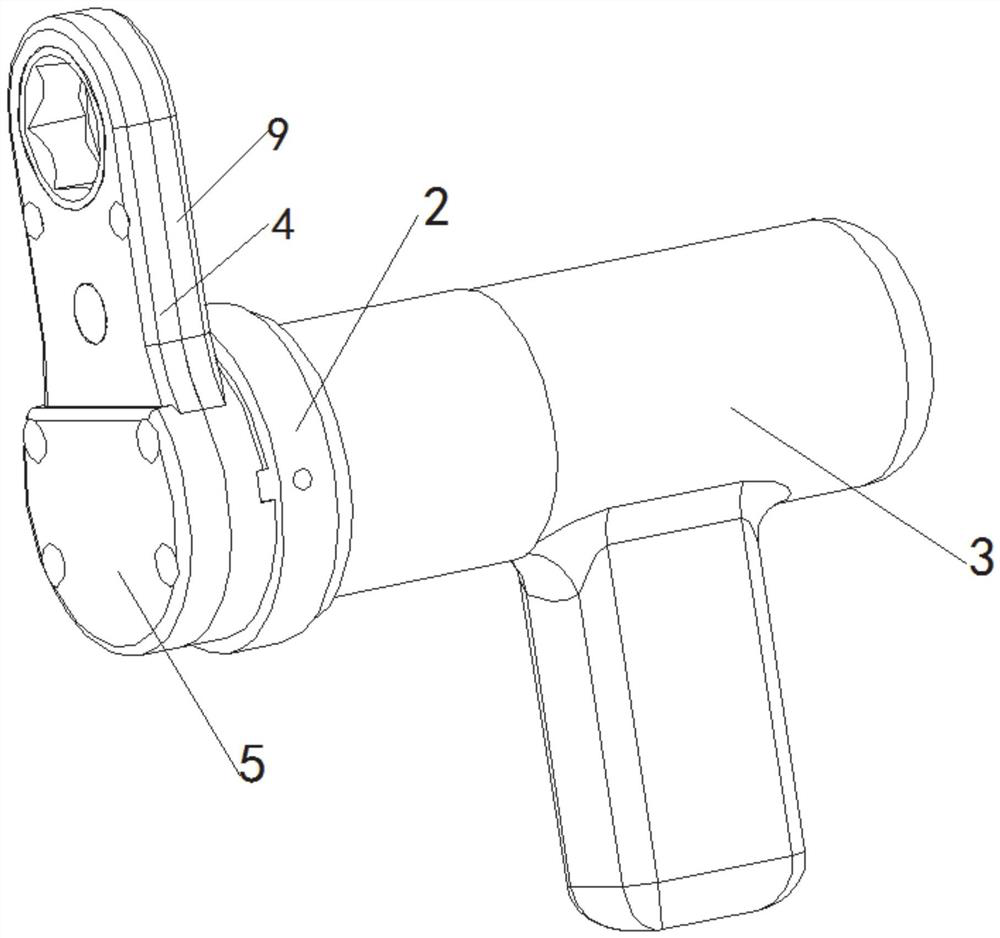

[0046] In a typical embodiment of the present invention, refer to figure 1 , figure 2 As shown, a wrench used in a narrow space includes a wrench host and a disassembly tool 1 that can be engaged with a bolt or a nut. The disassembly tool is vertically arranged with the drive shaft of the wrench host 3, and the wrench host is bent so as to facilitate work. It is easy to be held by personnel, and it is convenient to extend the disassembly tool into a relatively narrow space, with a certain degree of flexibility.

[0047] The wrench host 3 is a pneumatic wrench host or an electric wrench host, and the wrench host can be T-shaped, so that the pneumatic or electric power source drives the rotation of the transmission shaft 19, and then drives the work of the dismounting tool. Compared with the ratchet wrench, which requires manpower to operate, it can be Effectively improve the operation efficiency of disassembling nuts and bolts, and the single operation time is effectively red...

Embodiment 2

[0072] The difference between this embodiment and embodiment one is:

[0073] The transmission mechanism is a transmission belt, and the transmission belt meshes with the driving gear and the rack on the peripheral side of the sleeve respectively. Through the rotation of the driving gear, the rotation of the sleeve is driven by the transmission belt to realize the locking or dismounting of the bolts or nuts.

Embodiment 3

[0075] The difference between this embodiment and embodiment one is:

[0076] At least one first protrusion is provided on the side surface of the housing, that is, on the end surface of the second housing, and a first locking groove matched with the first protrusion is provided on one end of the connector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com