Single-layer woodworking hot press for heat balance processing

A heat balance and heat press technology, applied in veneer presses, plywood presses, wood processing appliances, etc., can solve the problems of different temperatures and affect processing quality, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

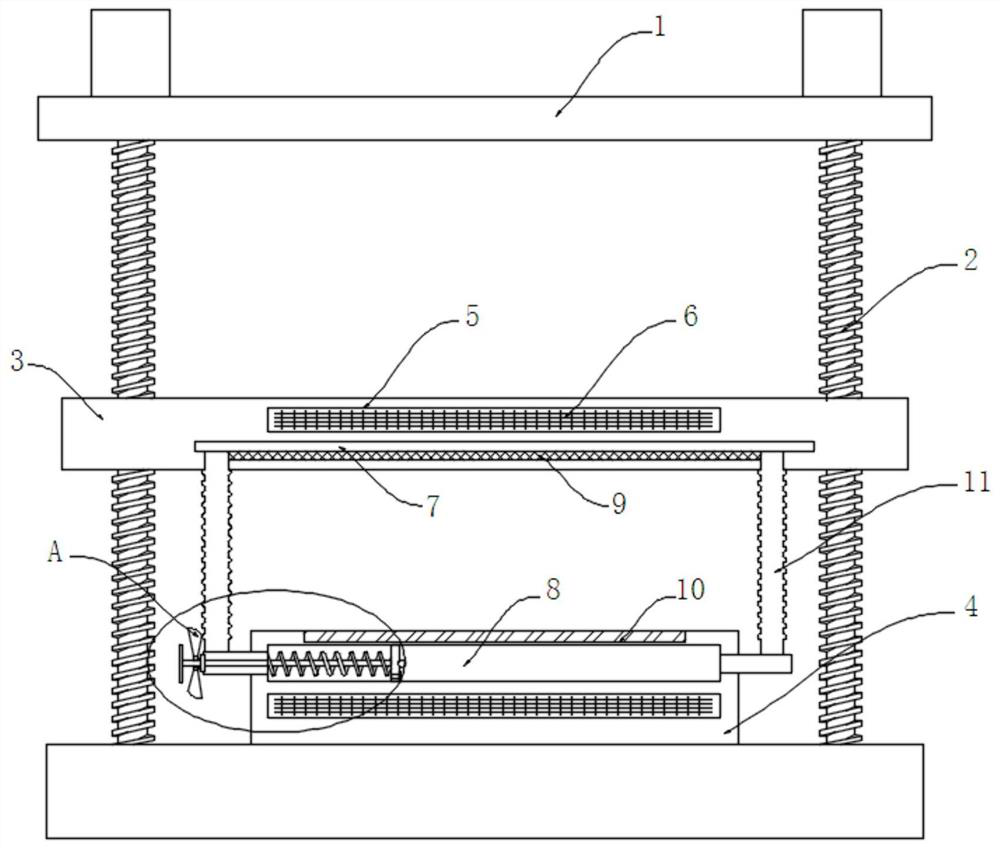

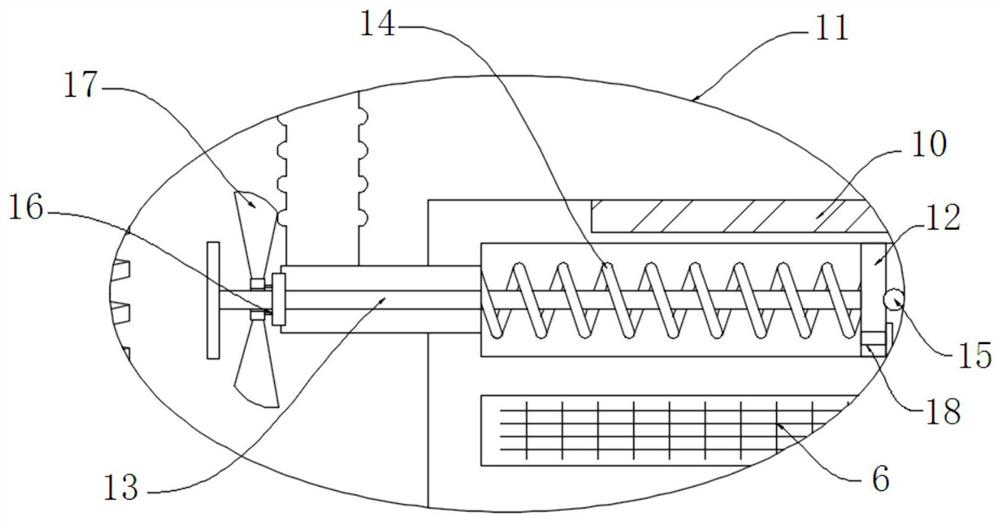

[0021] refer to Figure 1-2 , a single-layer woodworking heat press machine for heat balance processing, comprising a frame 1 and a plurality of screws 2, the plurality of screw rods 2 are jointly threaded with a heat pressing plate 3, the bottom of the frame 1 is fixedly connected with a fixed platform 4, and the fixed platform 4 A heating chamber 5 is opened in the heating chamber 5, and an electric heating wire 6 is fixedly connected to the heating chamber 5. The heating chamber 3 and the fixed platform 4 are respectively provided with a first balance chamber 7 and a second balance chamber on the side close to each other. 8. The hot pressing plate 3 is located at the bottom of the first balance chamber 7 and is provided with a guide layer 9, the top of the fixed platform 4 is fixedly connected with an electromagnet 10, and the second balance chamber 8 is connected with a circulation structure;

[0022] The circulation structure includes two return pipes 11, the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com