Medicine bottle packaging cap screwing device

A medicine bottle and bottle body technology, applied in the field of medicine bottle packaging capping devices, can solve the problems of high equipment cost, large space occupation, low capping speed, etc., and achieve the effects of saving manufacturing cost, easy processing and manufacturing, and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the drawings and specific embodiments.

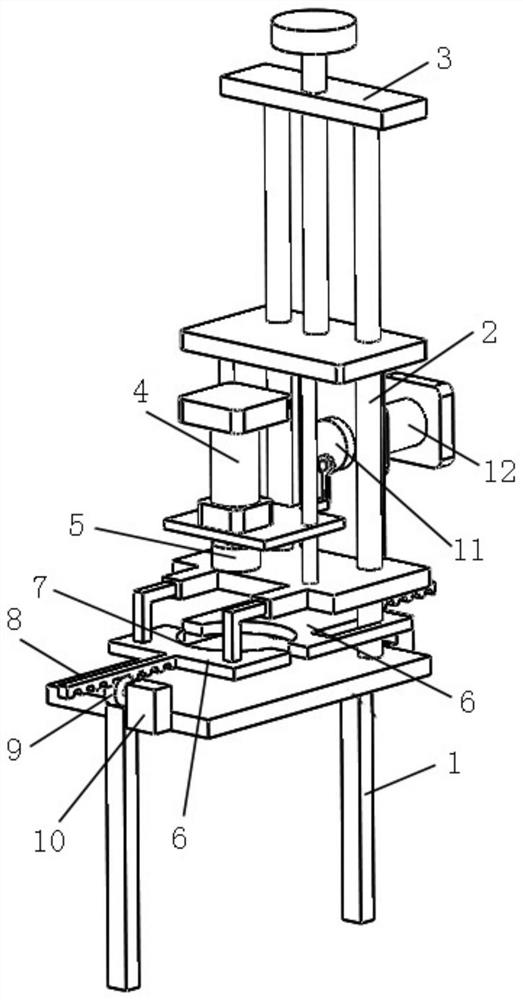

[0015] The present invention is a medicine bottle packaging screw cap device, such as figure 1 As shown, it includes a bracket 1, a column 2 is fixed on the bracket 1, and a bottle body fixing assembly is provided on the bracket 1, a movable frame 3 is arranged above the bottle body fixing assembly, the column 2 penetrates the movable frame 3, and the movable frame 3 is connected with a driving mechanism , The moving frame 3 moves up and down along the column 2, the moving frame 3 is provided with a motor a4 and a screw cap 5 connected together, and the inner wall of the screw cap 5 is a rough surface.

[0016] The bottle body fixing assembly includes two fixing plates 6 arranged oppositely and symmetrically. The opposite ends of the fixing plates 6 are provided with a semicircular notch 7, and the screw cap 5 is located directly above the center of the hollow p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap