Constant temperature heating system for fermentation tank

A constant temperature heating and fermentation tank technology, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biomass post-treatment, etc. Decomposition and transformation, high construction costs and other issues, to achieve the effect of flexible installation, easy heating and flow, and improved fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

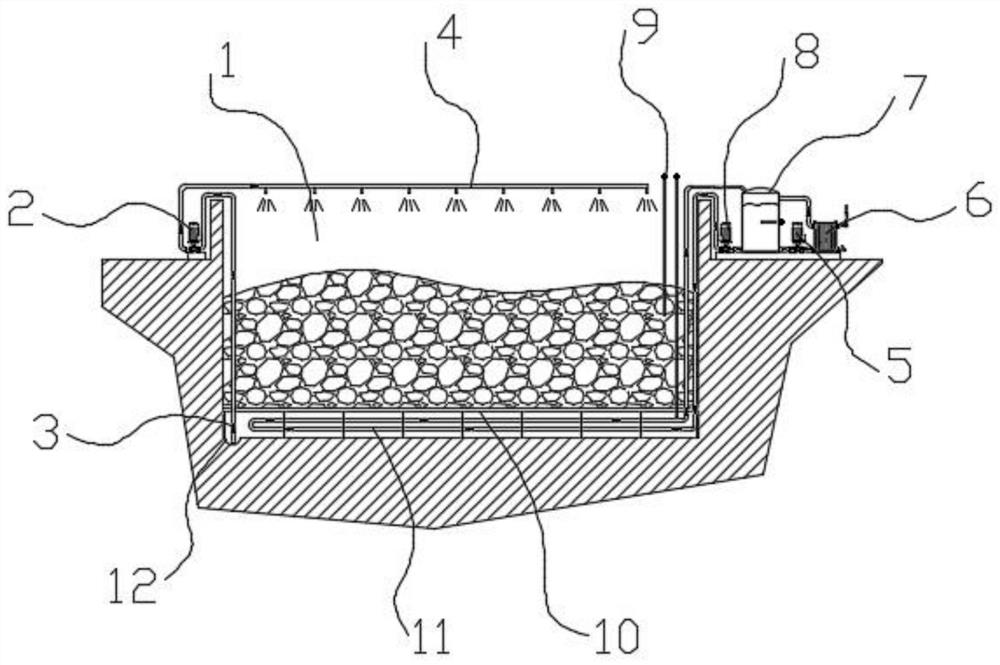

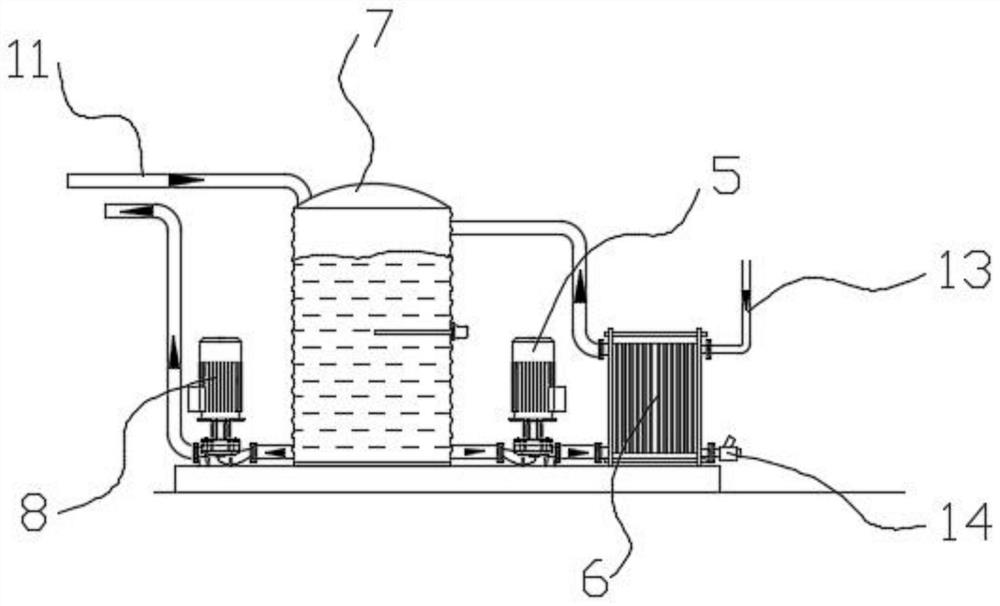

[0028] Such as figure 1 with figure 2 As shown, a constant temperature heating system for a fermentation tank includes a fermentation tank false bottom 10 located at the bottom of the fermentation tank 1 and a juice circulation mechanism located inside the fermentation tank 1, between the fermentation tank false bottom 10 and the bottom of the fermentation tank 1 There is a heating space, a heating mechanism is arranged in the heating space, the input end of the juice circulation mechanism is set inside the heating space, and the output end of the juice circulation mechanism is set on the top of the fermentation tank 1; Temperature sensor 9 for material temperature and temperature in heating space.

[0029] The working principle of the above technical solution is as follows:

[0030] In the present invention, a false bottom 10 of the fermentation tank is installed at the bottom of the fermentation tank 1 to separate the solids and liquids in the fermentation tank 1 to facilitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com