Metal part deoiling and cleaning device after heat treatment

A technology for metal parts and cleaning devices, which is used in filtration treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. Problems such as poor quality and efficiency, to achieve the effect of improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

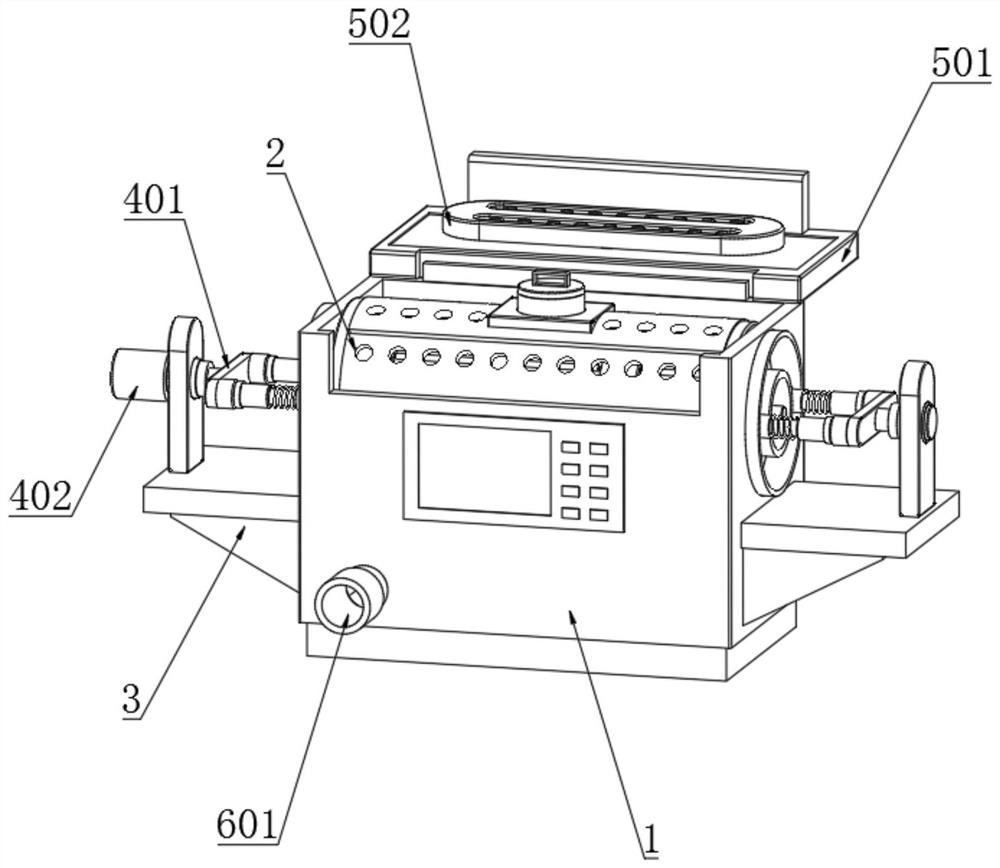

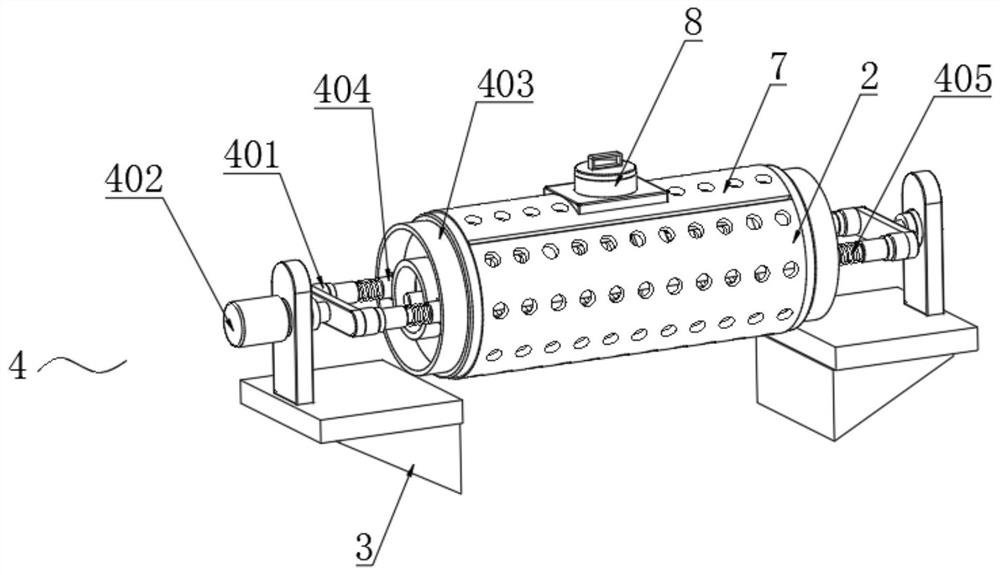

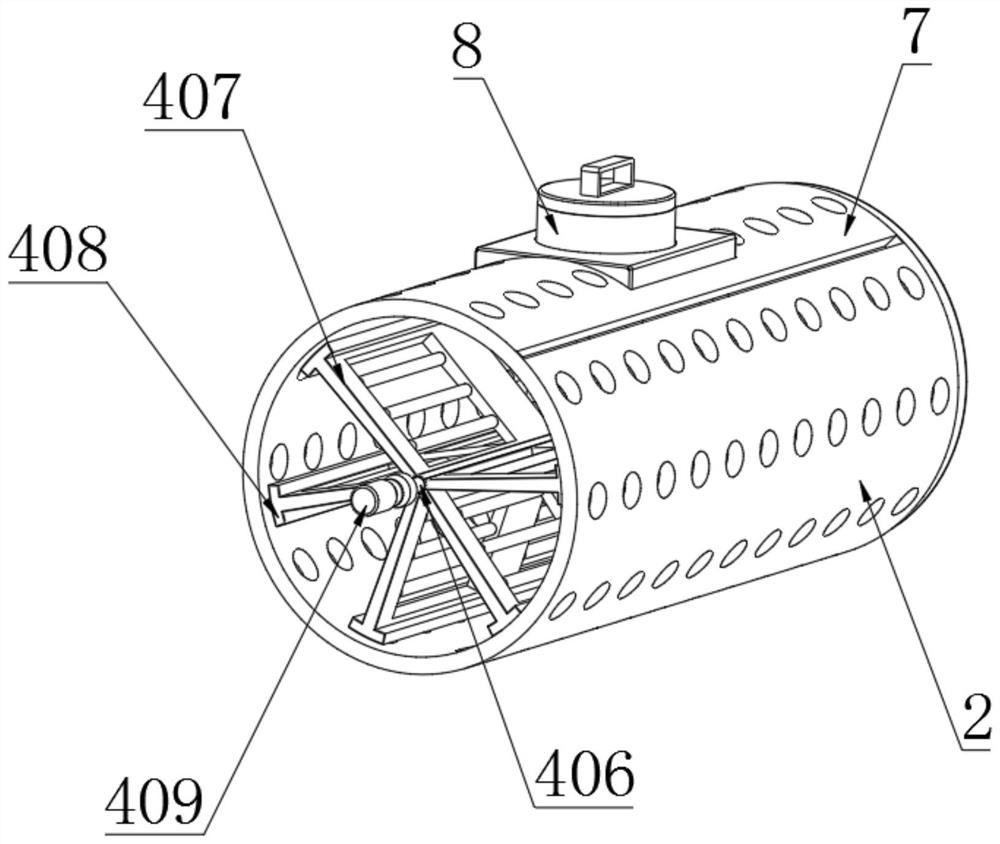

[0026] Please refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 ,in, figure 1 A structural schematic diagram of a preferred embodiment provided by the present invention; figure 2 for figure 1 Schematic diagram of the structure of the rotating assembly shown; image 3 for figure 1 The structural diagram of the installation of the valve baffle shown; Figure 4 for figure 1 Schematic diagram of the liquid inlet assembly shown; Figure 5 for figure 1 Schematic diagram of the structure of the blowdown assembly shown. A degreasing and cleaning device for metal parts after heat treatment, comprising a cleaning frame 1, a cleaning screen cylinder 2 is embedded in the top of the cleaning frame 1, and a triangular support 3 is installed on both sides of the outer wall of the cleaning frame 1, and two triangular supports The top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com