A spiral liquid conductance adjustable temperature sensor

A temperature sensor, spiral technology, applied in thermometers, thermometers using electric/magnetic elements that are directly sensitive to heat, thermometer parts, etc., to achieve high precision, good stability, and novel structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

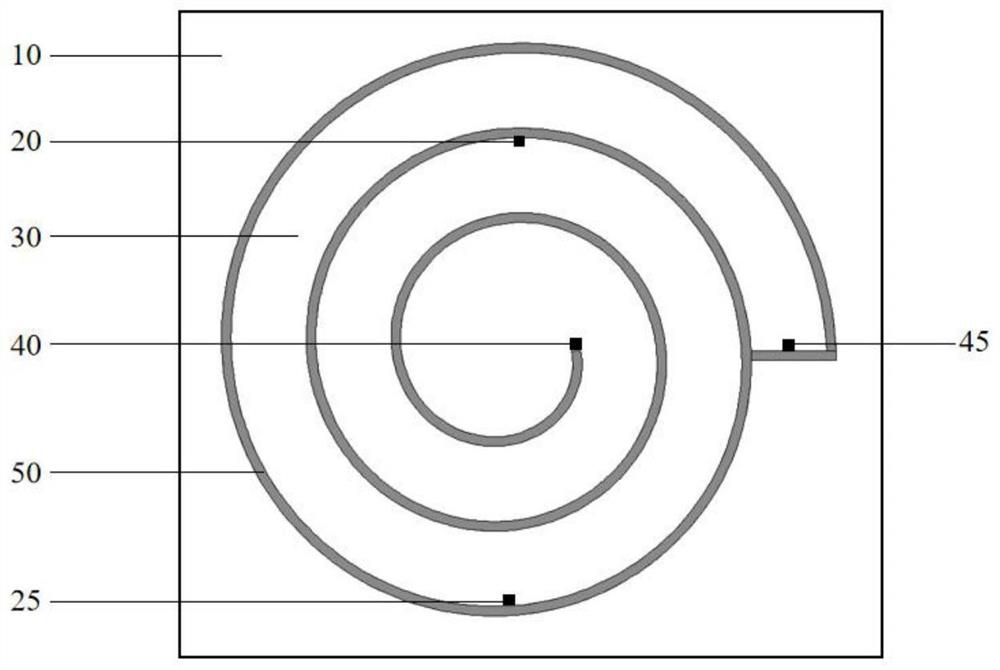

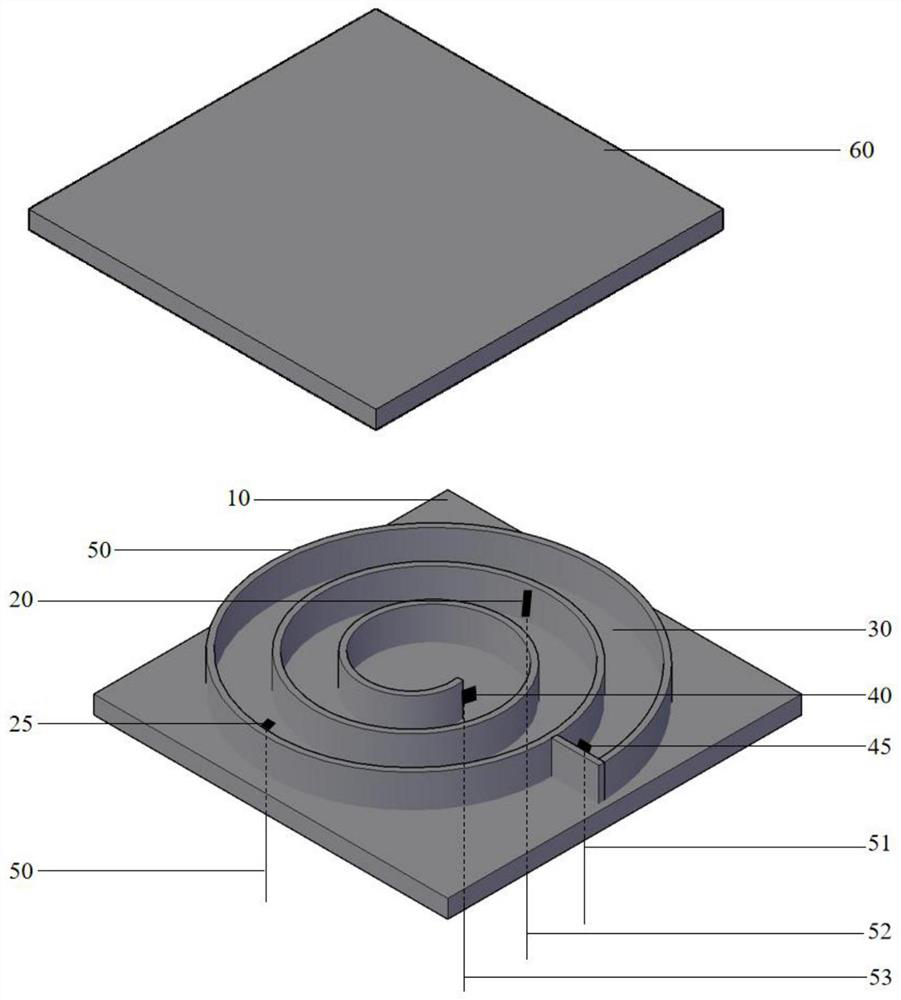

[0022]The spiral liquid conductance adjustable four-electrode temperature sensor involved in this embodiment has a main structure including a lower chassis 10, a first voltage electrode 20, a second voltage electrode 25, a liquid 30, a first current electrode 40, and a second current electrode 45 , spiral cavity 50, and the upper chassis 60 symmetrical to the lower chassis 10 and the homogeneous wires 51, 52, 53 and 54 of the connecting electrodes; The cavity 50 is fixed with the first voltage electrode 20 and the second voltage electrode 25 respectively at the corresponding position of the cavity 50; A current electrode 40 and a second current electrode 45 are filled with the liquid 30 in the spiral cavity inside the cavity 50, and the upper side of the cavity 50 is sealed with an upper chassis 60; the upper chassis 60 corresponds to the structure of the lower chassis 10 , the two are hermetically combined to form a box-shaped spiral cavity 50 with a closed structure.

[002...

Embodiment 2

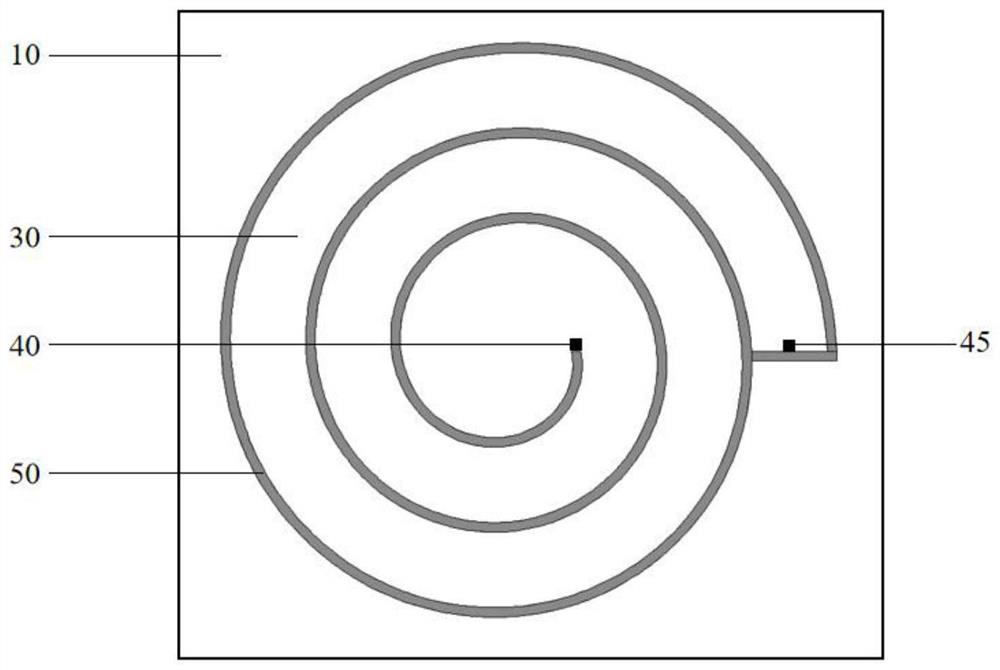

[0032] The main structure of the spiral two-electrode liquid conductance adjustable temperature sensor involved in this embodiment is similar to the four-electrode, including the lower chassis 10, the liquid 30, the first current electrode 40, the second current electrode 45 and the spiral cavity 50, As well as the upper chassis 60 symmetrical to the lower chassis 10 and the wires 51 and 53 connecting the electrodes, the connection principles and structures of the components correspond to those of the first embodiment.

[0033] For the two current electrodes involved in this embodiment, a constant AC excitation is applied to both ends, and the resistance value of the liquid 30 in the cavity 50 is obtained according to the measured voltage and current. The temperature can be deduced; the precise and stable measurement of the temperature under the external high pressure can be realized through the above structure.

[0034] The sensor involved in this embodiment can be applied to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com