Vehicle low-voltage wiring harness product design method

A product design, low-voltage wire technology, applied in the application of stable tension/pressure testing material strength, continuity testing, instruments, etc., can solve the problems of complex automotive wiring harness design, increased difficulty, large wiring harness, etc., to shorten the design Cycle and ensure the effect of smooth mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The principle and spirit of the present invention will be described below with reference to several exemplary embodiments. It should be understood that these embodiments are given only to enable those skilled in the art to better understand and implement the present invention, rather than to limit the scope of the present invention in any way.

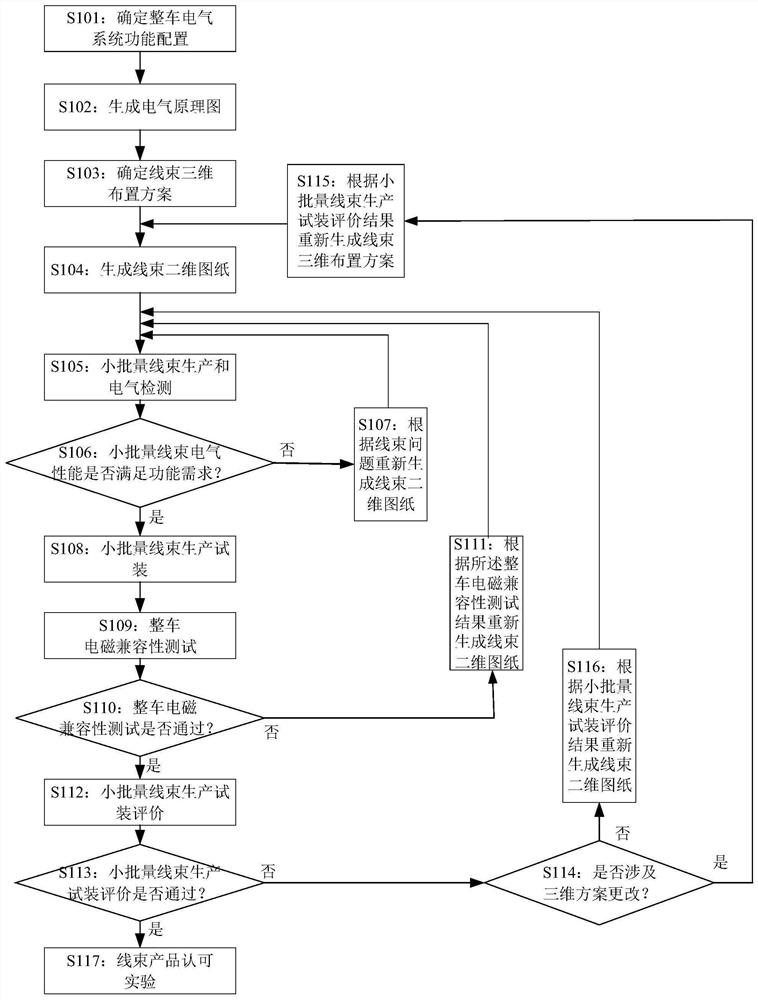

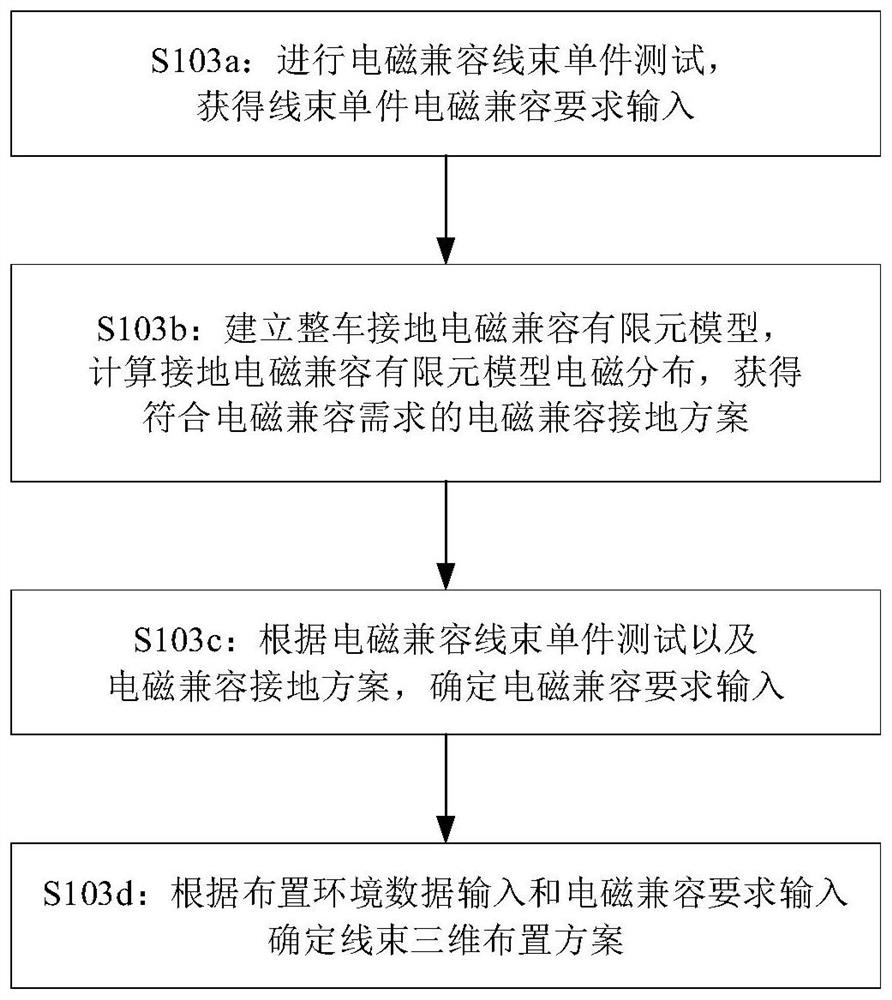

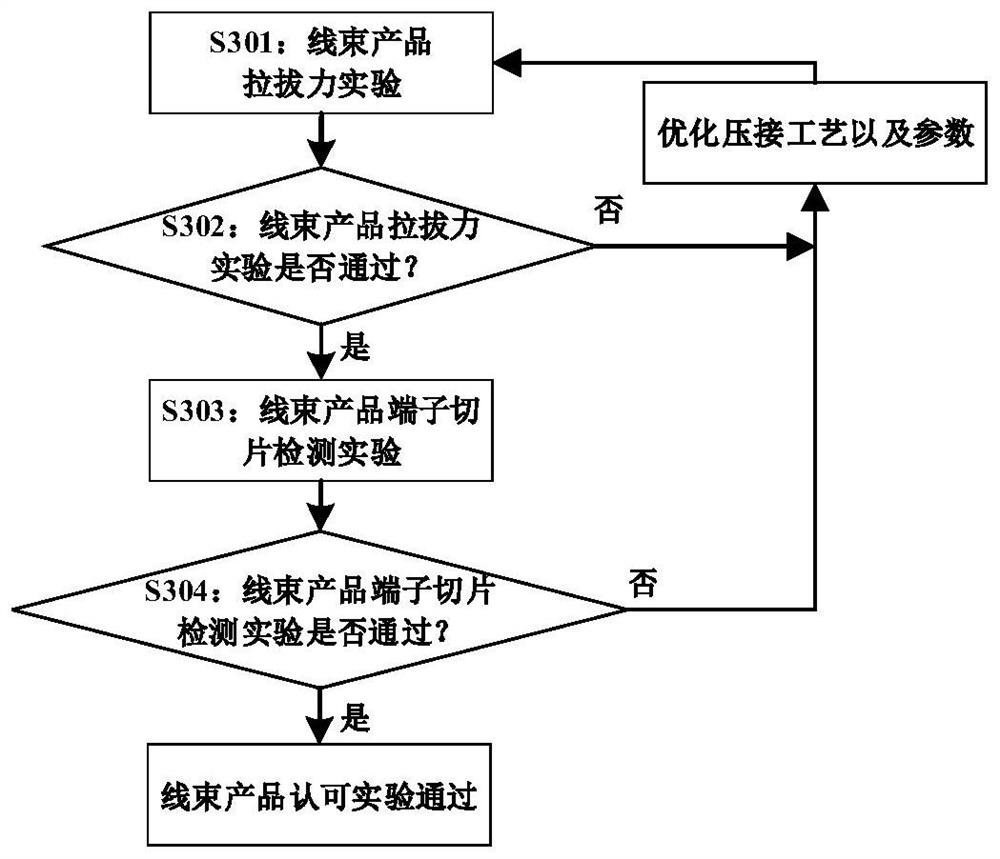

[0052] In view of the deficiencies in the existing low-voltage wiring harness product design methods, the purpose of the present invention is to provide a comprehensive electromagnetic compatibility design method for low-voltage wiring harness products. An embodiment of the present invention provides a method for designing a vehicle low-voltage wire harness product. refer to figure 1 , which shows a flowchart of a method for designing a vehicle low-voltage wire harness product according to an embodiment of the present invention. Such as figure 1 As shown, the method includes steps S101-S117.

[0053] In step S101, according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com