Robot positioning control method and system based on point cloud normal vector direction clustering servo

A robot positioning and normal vector direction technology, applied in the field of robot positioning control, can solve problems such as low precision and poor positioning stability, and achieve the effect of improving time efficiency and high-precision positioning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

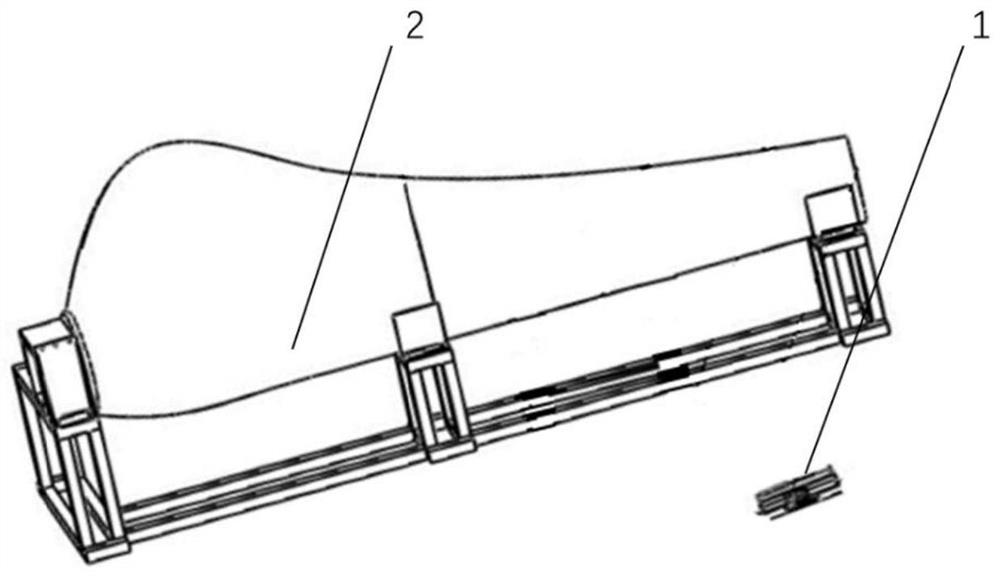

[0050] A robot positioning control method based on point cloud normal vector direction clustering servo, wherein, the robot has six degrees of freedom of motion, and is fixedly connected with an RGBD depth camera, consisting of the robot and the RGBD depth camera fixedly connected with it figure 1 In the visual platform 1 shown in , the target to be positioned 2 is figure 1 the blade shown;

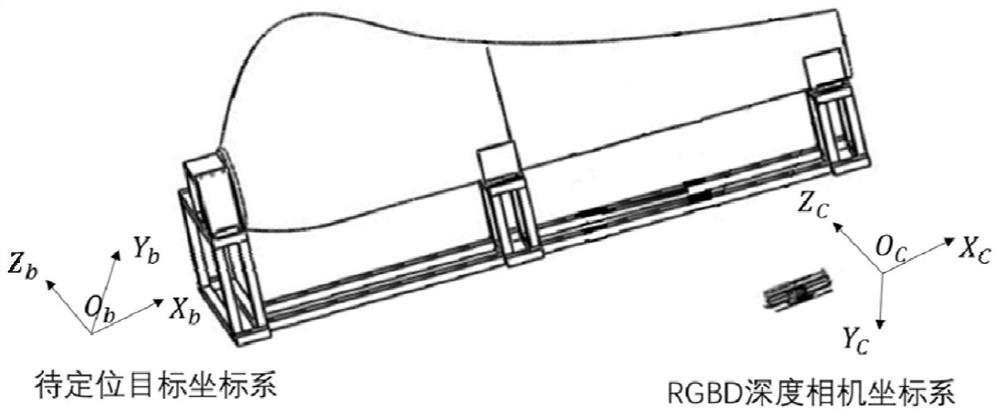

[0051] In order to use the RGBD depth camera to obtain the point cloud image of the target to be located, the coordinate system of the target to be located and the coordinate system of the RGBD depth camera are respectively constructed, as shown in figure 2 shown;

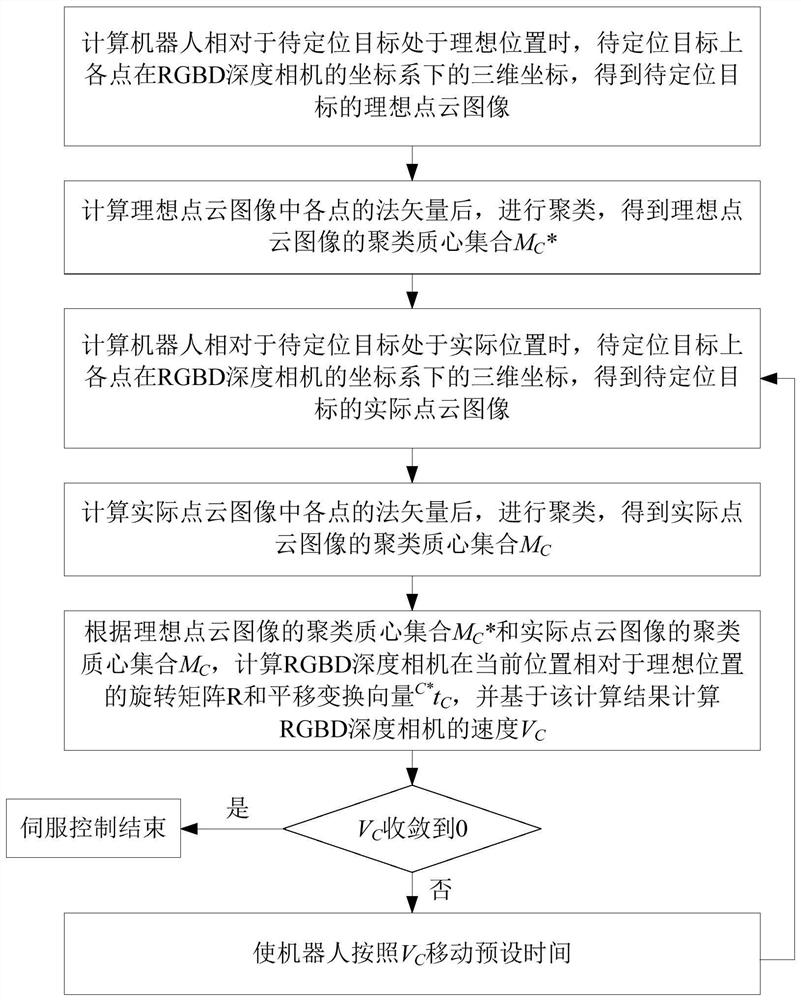

[0052] Such as image 3 As shown, the robot positioning control method based on point cloud normal vector direction clustering servo provided by this embodiment includes the following steps:

[0053] (S1) Calculate the three-dimensional coordinates of each point on the target to be positioned in the coordinate system of th...

Embodiment 2

[0080] A robot positioning control system based on point cloud normal vector direction clustering servo, including: a positioning control module and a vision platform;

[0081] The visual platform consists of a robot with six degrees of freedom of movement and an RGBD depth camera fixedly connected to it;

[0082] The positioning control module includes: an ideal point cloud image acquisition unit, a first cluster centroid set acquisition unit, an actual point cloud image acquisition unit, a second cluster centroid set acquisition unit, a speed acquisition unit and a movement control unit;

[0083] The ideal point cloud image acquisition unit is used to calculate the three-dimensional coordinates of each point on the target to be positioned in the coordinate system of the RGBD depth camera when the robot is in an ideal position relative to the target to be positioned, to obtain an ideal point cloud image of the target to be positioned, and then Trigger the first cluster centro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com