A kind of production technology of cold type sanitary napkin

A production process and technology of sanitary napkins, applied in sanitary napkins, medical science, absorbent pads, etc., can solve the problems of poor comfort of cold sanitary napkins, achieve the effect of not being easily irritated, avoiding the possibility of odor, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

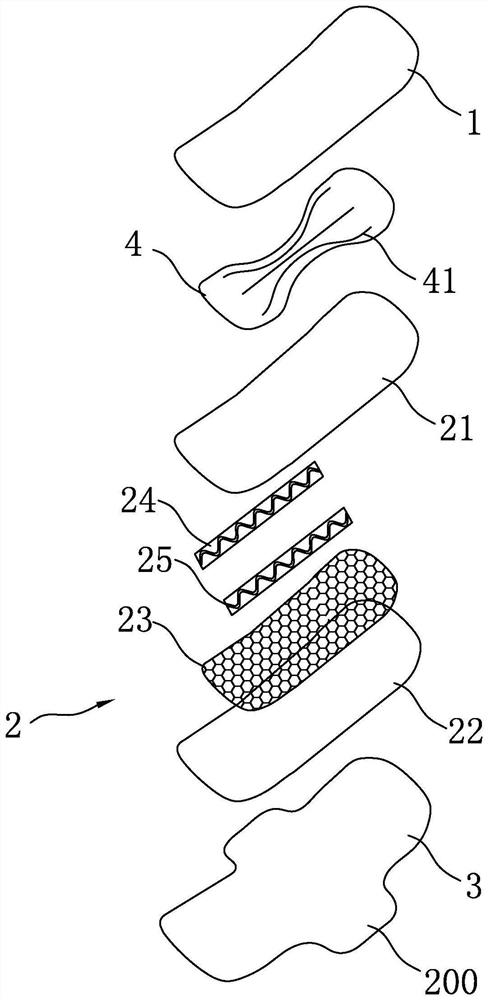

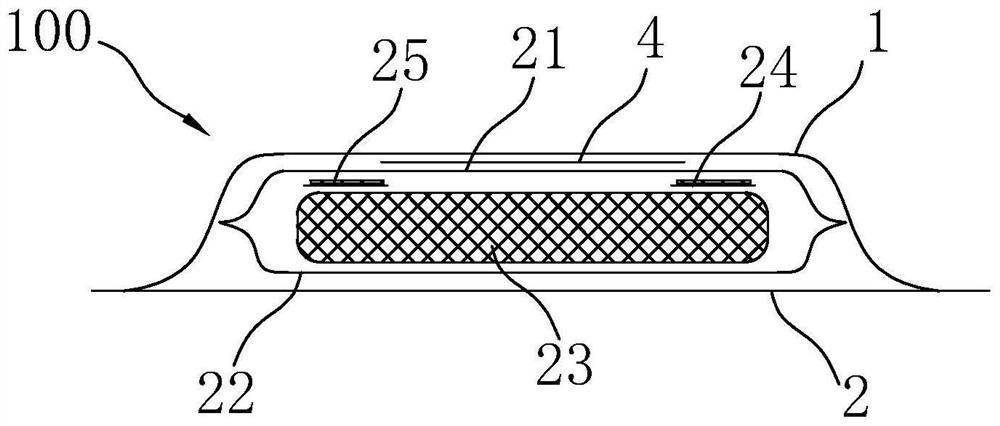

[0037] refer to figure 1 , figure 2 , image 3 , a kind of production technology of ice-cold type sanitary napkin, comprises the following steps:

[0038] 1. Prepare a liquid-permeable surface layer;

[0039] 2. Preparation of absorbent core;

[0040] 3. Preparation of a liquid-impermeable bottom layer;

[0041] 4. Lay the products in steps 1, 2, and 3 and connect them together;

[0042] 5. Carry out arc trimming to the product of step 4;

[0043] Six, the product of step five is cut into individual products to make finished products, and said step two comprises the following steps:

[0044] a. Sizing glue on the upper surface of the lower cladding layer, and laying a layer of liquid-absorbing material to form a core material layer;

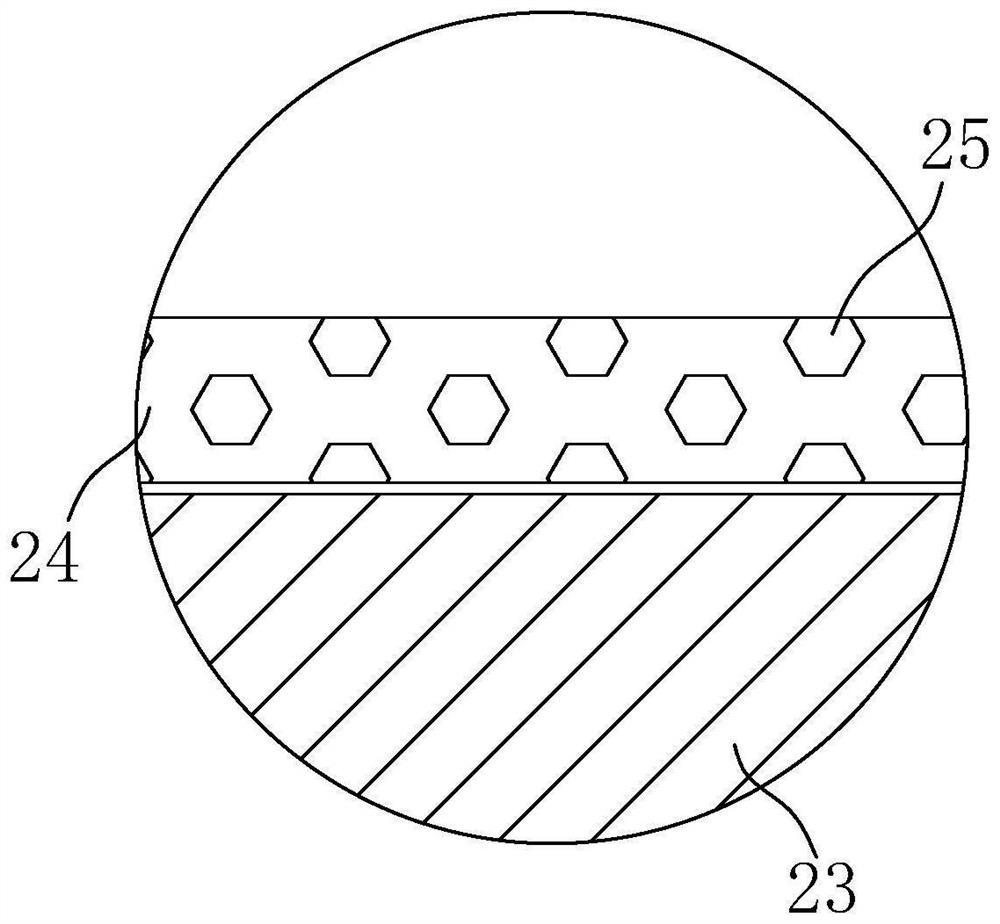

[0045] B, get two fluffy non-woven fabrics, set adhesive on two fluffy non-woven fabrics, then arrange cool microcapsule particles on fluffy non-woven fabrics;

[0046] c. Lay two fluffy non-woven fabrics on the lateral sides of the core...

Embodiment 2

[0060] Compared with Example 1, in order to reduce the material loss caused by the spraying method in production, here, on the setting method of the cool microcapsules, step b6 is also included: the cool microcapsule particles obtained by the above b5 are mixed with equal mass Than binding agent, dispersant mix and make described cool microcapsule finishing liquid;

[0061] It is then coated on the fluffy nonwoven.

[0062] The invention adopts special cooling microcapsule particles, which can be attached and filled in fluffy non-woven fabrics. Utilizing the special function of microcapsules, after the raw materials with cooling function are made into microcapsules, the volatilization loss is small. When the temperature rises, the raw materials with cooling function will be released slowly from the microcapsules, making it have a cooling feeling when worn, improving comfort, reducing discomfort, and lasting coolness at the same time, and compared with direct spraying of coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com