Air purification system of textile workshop for textile production

An air purification system and workshop technology, applied in the field of textile production, can solve the problems of pungent smell, unguaranteed physical health, affecting the breathing health of workers, etc., and achieve the effect of full combination and better effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

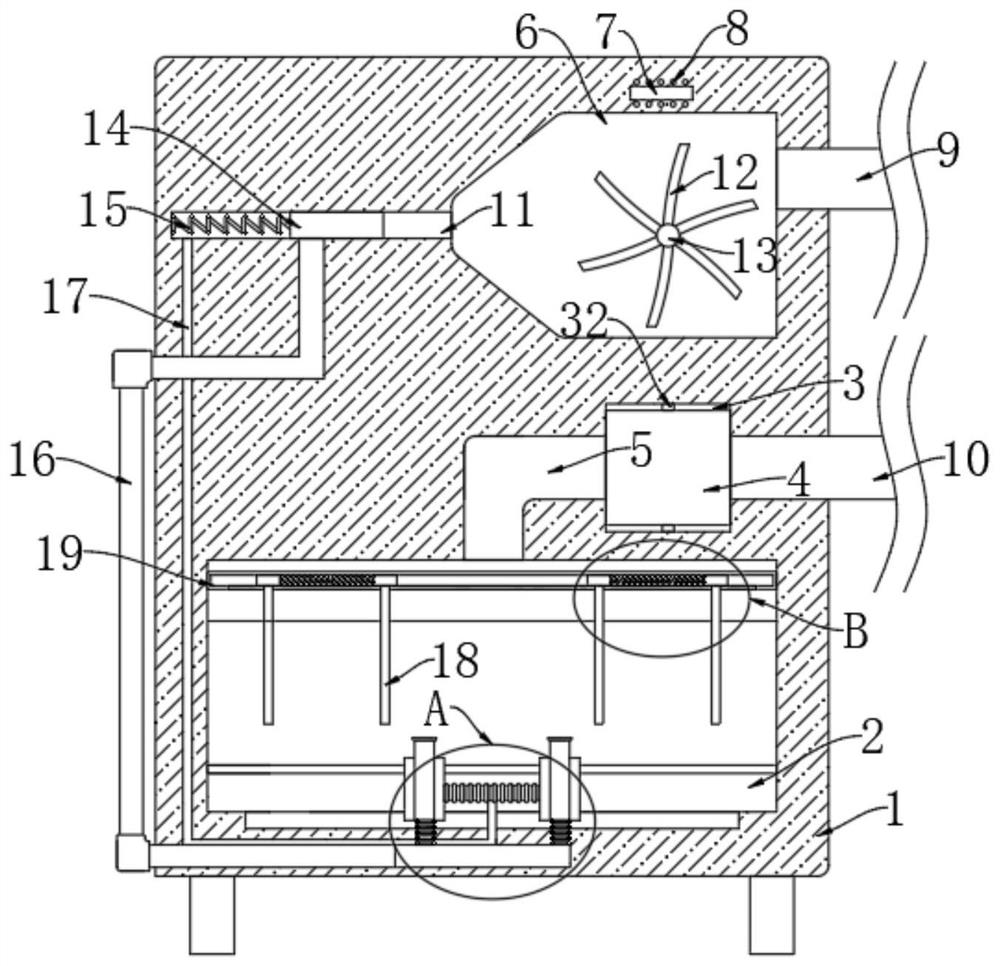

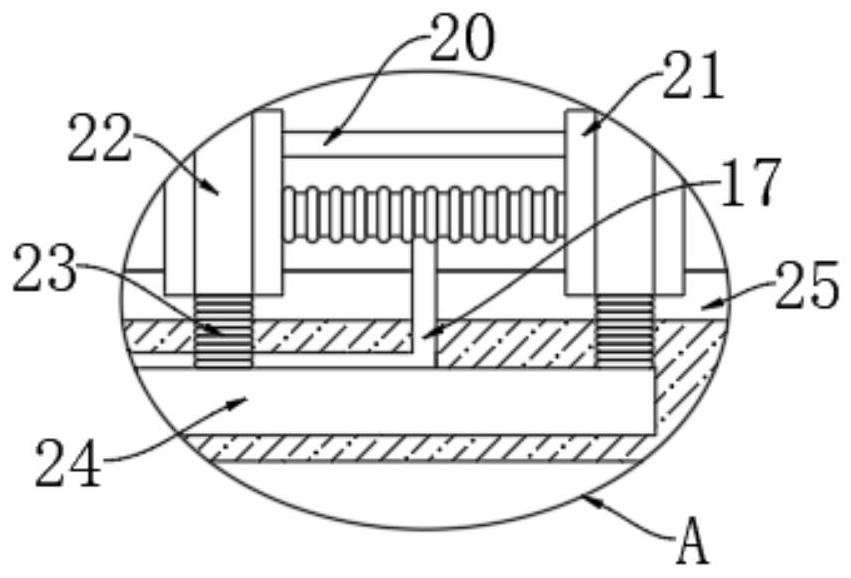

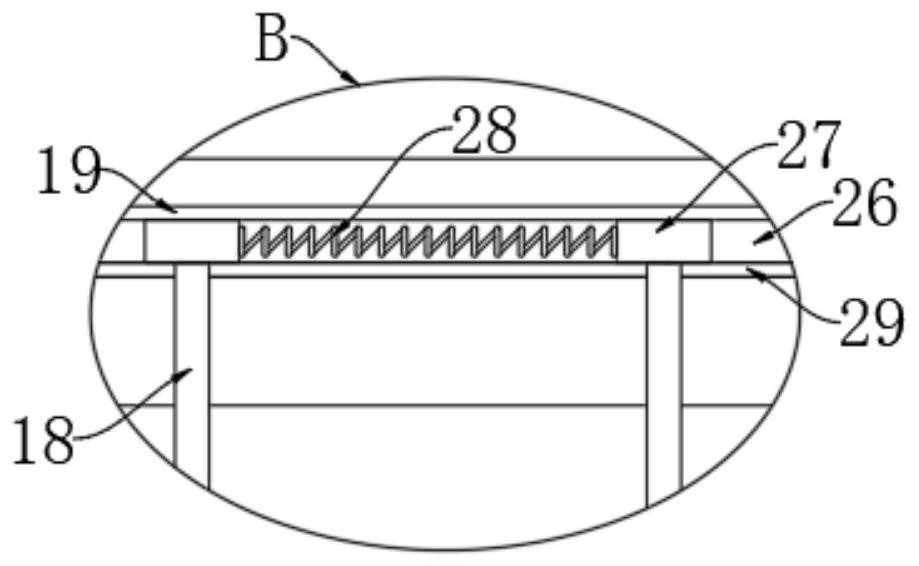

[0025] refer to Figure 1-4 , an air purification system for a textile workshop for textile production, comprising a housing 1, a plurality of support blocks are fixedly connected to the lower end of the housing 1, and a trigger chamber 6, a filter chamber 3 and a filter chamber 3 are arranged in the housing 1 from top to bottom In the processing chamber 2, the left side of the trigger chamber 6 is provided with a transverse groove 11 communicating with it, the right side of the trigger chamber 6 communicates with the outside world through the air inlet pipe 9, and the right side of the filter chamber 3 communicates with the outside world through the air outlet pipe 10;

[0026] The trigger module, the trigger module includes a rotating shaft 13 horizontally arranged in the trigger chamber 6, the two ends of the rotating shaft 13 are respectively connected to the front and rear inner walls of the trigger chamber 6 in rotation, and the rotating shaft 13 is uniformly fixedly conn...

Embodiment 2

[0037] refer to Figure 5-6 , The difference between this embodiment and Embodiment 1 is that the lower end of the rotating rod 32 is rotationally connected with the inner bottom of the filter chamber 3, and the upper end of the rotating rod 32 extends into the trigger chamber 6 and is fixedly connected with the transmission gear 31, the rotating shaft 13 A crown gear 30 is fixedly connected to the top, and the crown gear 30 meshes with the transmission gear 31 .

[0038] In this embodiment, the rotation of the rotating shaft 13 will drive the crown gear 30 to rotate, the rotation of the crown gear 30 will drive the transmission gear 31 to rotate, and the rotation of the transmission gear 31 will drive the rotation rod 32 to rotate, so that the filter cartridge 4 is in a rotating state, thereby The entire filter layer of the filter cartridge 4 is consumed evenly, and the overall service life thereof is increased.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap