A high-carbon steel continuous casting production method with air-mist full-water combined cooling

A production method and gas mist cooling technology, which is applied in the field of high carbon steel continuous casting process, can solve the problems of large carbon center segregation, cracks, low shrinkage cavity and high shrinkage porosity of casting slab, so as to improve the quality of high carbon steel Quality, reduction of drawing broken wire rate, good internal quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

[0014] An aerosol method for producing high-carbon steel compositions all water cooled, comprising the following:

[0015] (1) produced with section two caster 160mm × 160mm high carbon steel, and controlling the carbon content 0.77% and 0.82%.

[0016] (2) the degree of superheat is controlled Tundish 18 ~ 32 ℃.

[0017] (3) cooling the high carbon steel with all water mist cooling devices.

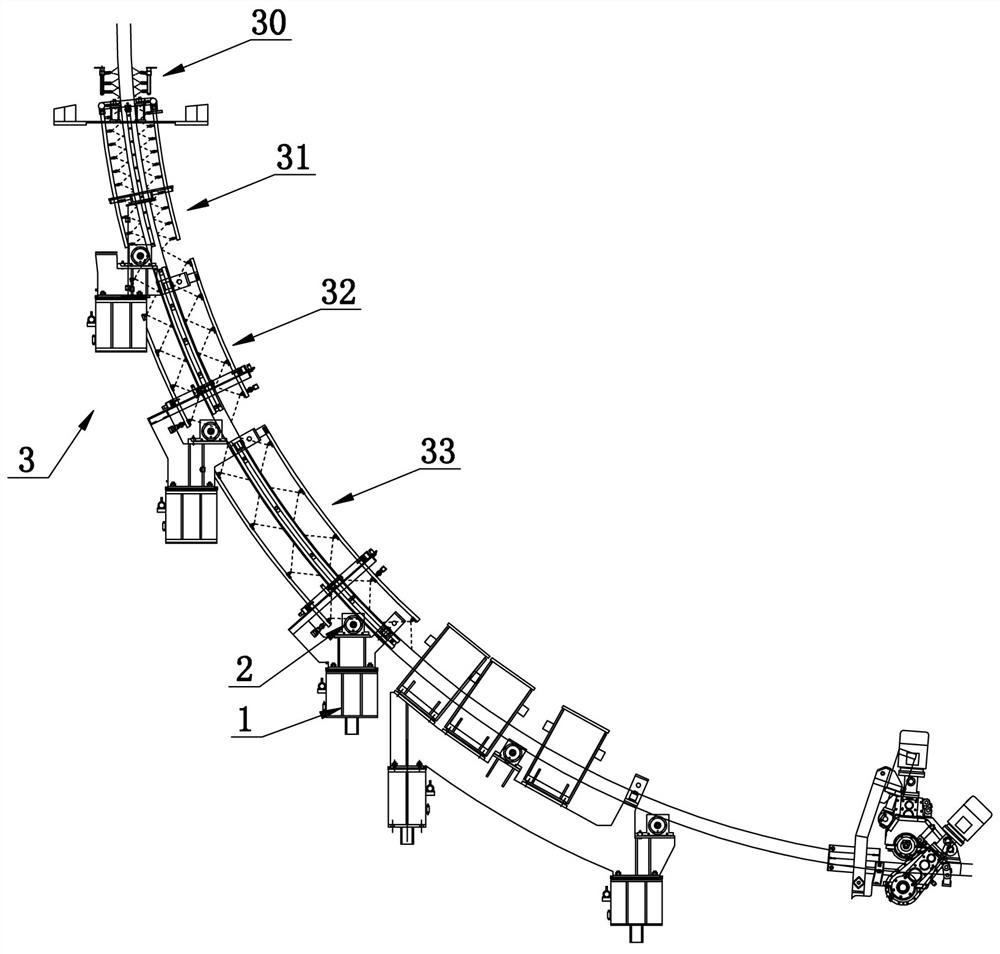

[0018] like figure 1 Shown, all water mist cooling equipment of existing conventional equipment is mainly supported by the apparatus 1, the guide means 2, 3 consisting of a cooling device. The cooling device 3 comprises a foot mold roll segment, segment 30 that is 0; further comprising a secondary cooling spray section, is divided into sections I 31, II and III 32 section 33 section.

[0019] like figure 1 Shown, three rows of section 30 0 PZ5965QZ all water cooled nozzle, 31 is a six-row section of the I whole PZ4565QZ water cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com