Finishing treatment equipment for tappet surfaces

A technology for surface finishing and processing equipment, applied in the field of mechanical equipment, can solve the problems of poor surface flatness, low processing speed, and low processing quality of tappets, and achieve the effects of improving practicability and reliability and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

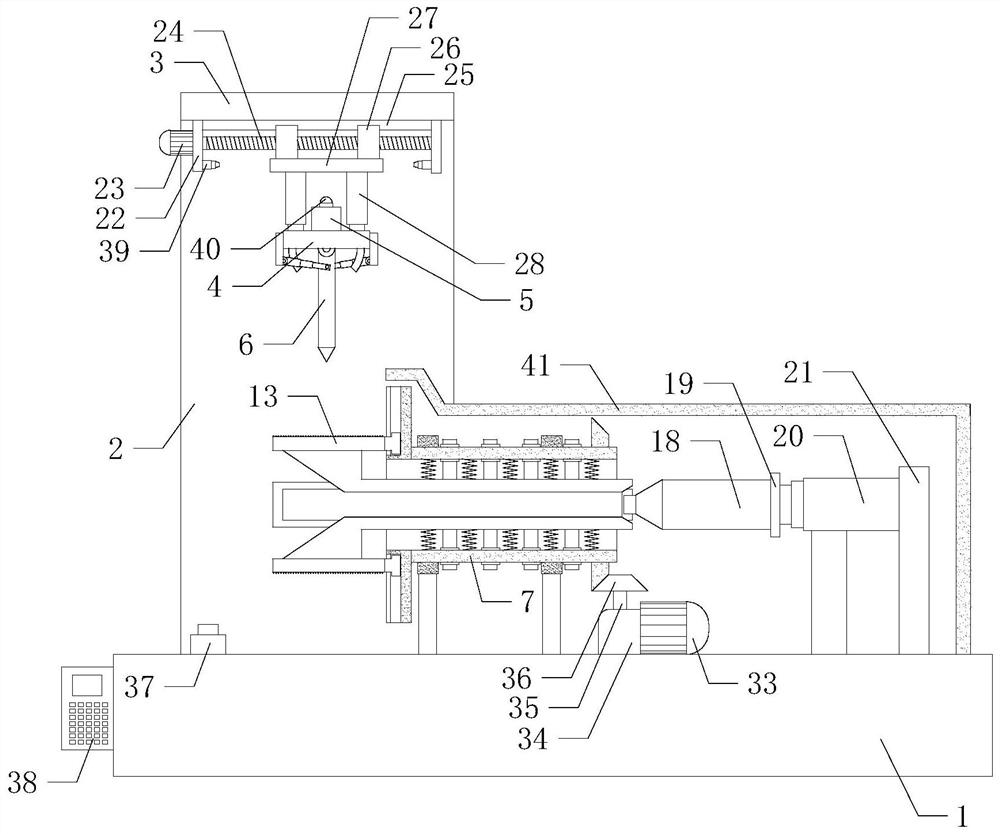

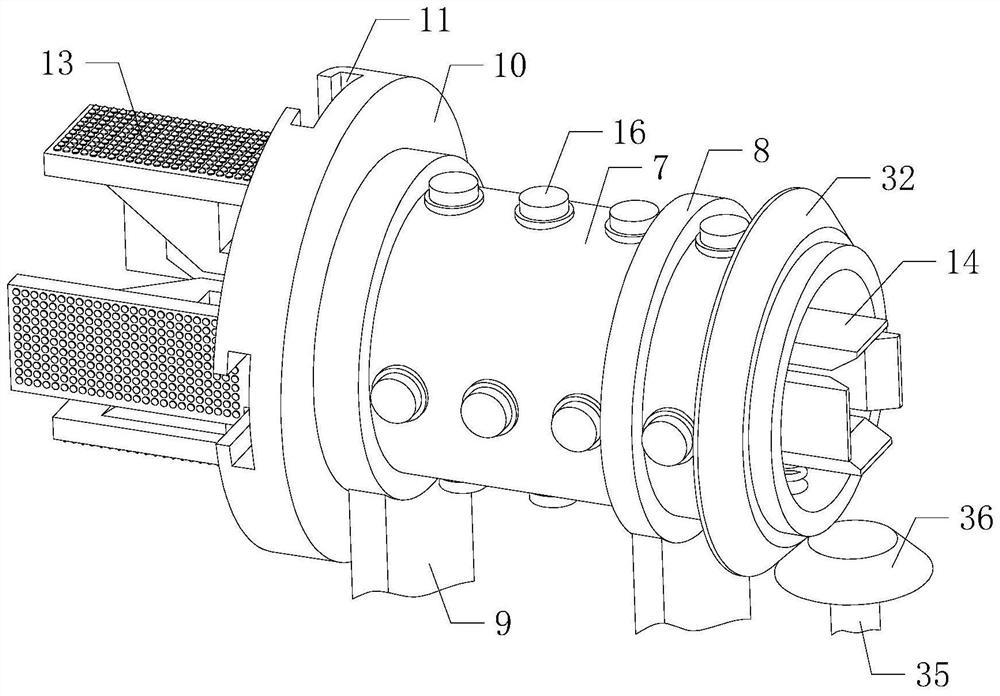

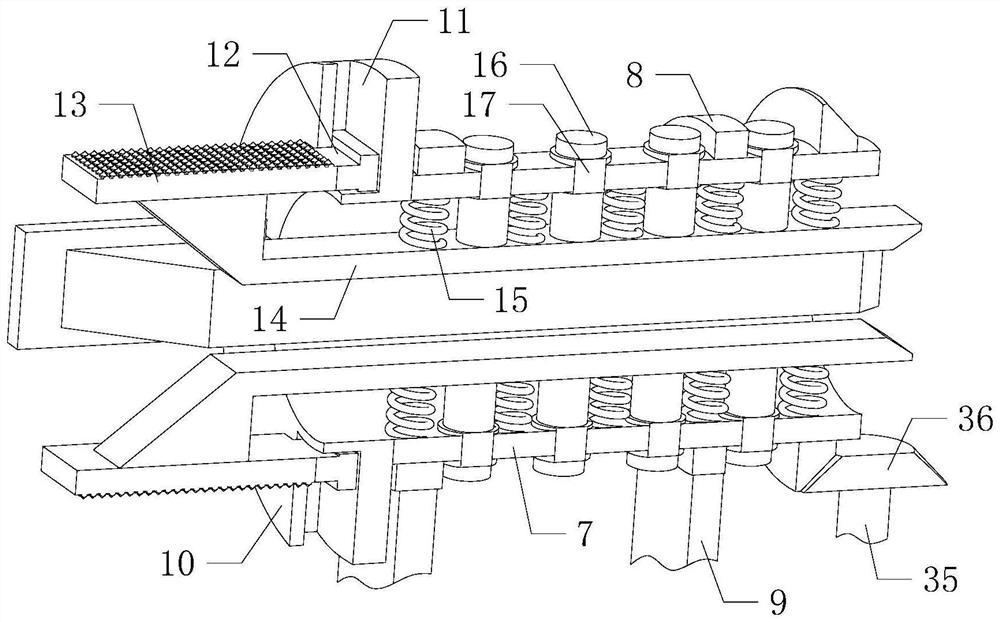

[0019] Such as Figure 1 to Figure 4 As shown, a kind of tappet surface finishing processing equipment of the present invention, when it is working, tappets are set on the outside of four groups of push plates 13, open the first cylinder push rod 20, the left end of the first cylinder push rod 20 Promote rotating disc 19 and extruding post 18 to move to the left, and the left end of extruding post 18 contacts with the right end inclined surface of four groups of pushing frame 14, because extruding post 18 left ends are set to taper, the left end of extruding post 18 is opposite to four Group push frame 14 is extruded, and four groups of push frame 14 moves to the outside,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com