Plate structures of all-ceramic, modular and fast-assembled floor and wallboard and preparation method

A modular and plate technology, which is applied in chemical instruments and methods, household walls, lamination devices, etc., can solve the problems of heavy weight, fragile ceramic rock plates, and the inability to realize quick installation, so as to increase structural strength and texture Beautiful, anti-fragmentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

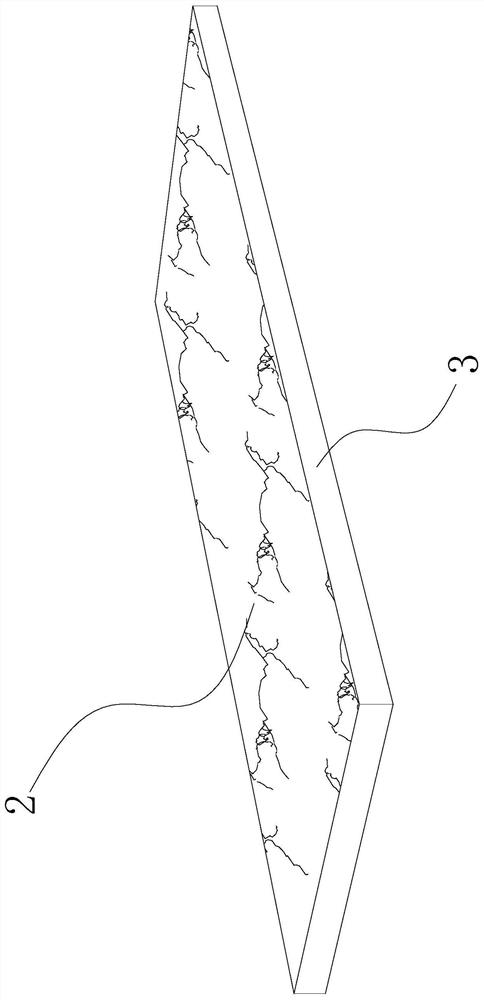

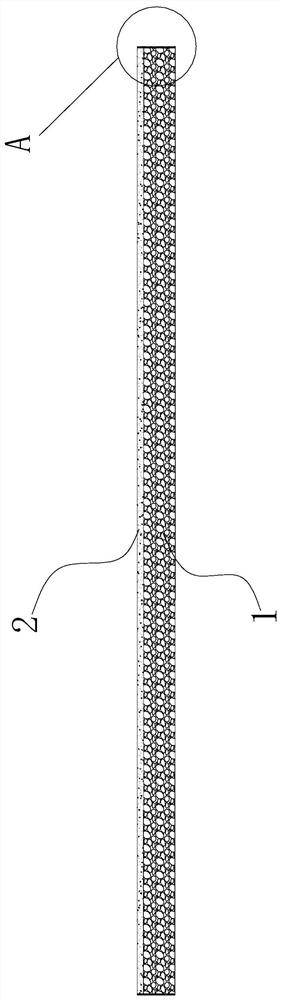

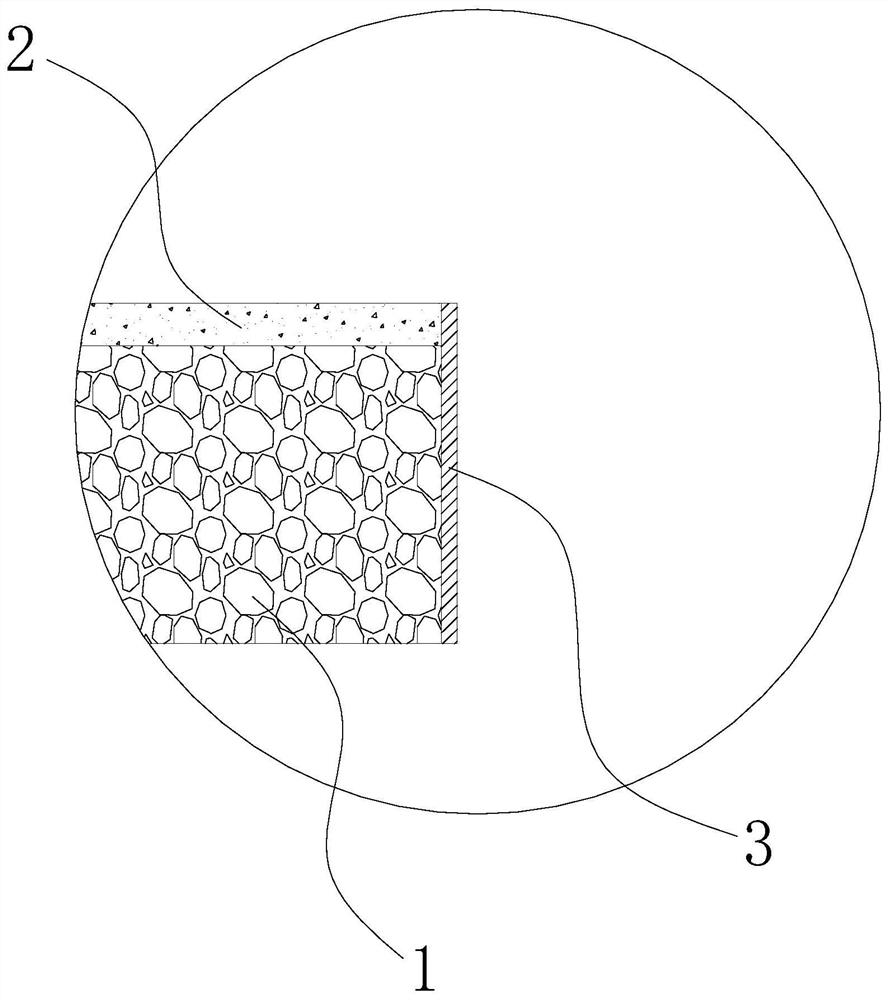

[0037] see Figure 1-3 , an all-ceramic, modular, quick-install floor plate structure, including horizontally arranged rectangular ceramic foam plates 1, the thickness of the ceramic foam plates 1 is 20-25mm, and the upper side of the ceramic foam plates 1 is attached with a ceramic foam plate 1 The matching ceramic rock plate 2, the thickness of the ceramic rock plate 2 is 3-6mm, the foam ceramic plate 1 is provided with a PVC plastic edge band 3, and the width of the PVC plastic edge band 3 just covers the foam ceramic plate 1 and the ceramic rock plate 2.

Embodiment 2

[0039] see figure 1 , Figure 4-5 , an all-ceramic, modular, and quick-install floor plate structure, including horizontally arranged rectangular ceramic foam plates 1, the thickness of the ceramic foam plates 1 is 12-20mm, and the ceramic foam plates 1 are coated with Matching metal square tube 4, ceramic rock plate 2 is pasted on the upper side of foam ceramic plate 1, the thickness of ceramic rock plate 2 is 3-6mm, ceramic rock plate 2 just covers foam ceramic plate 1 and metal square tube 4, metal The square tube 4 is provided with PVC plastic edge strips 3 on the outside, the width of the PVC plastic edge strips 3 just covers the foam ceramic plate 1 and the ceramic rock plate 2, the metal square tube 4 and the ceramic rock plate 2, and the PVC plastic edge strip 3 Glue lines arranged along the length direction of the metal square tube 4 are provided on the contact side.

Embodiment 3

[0041] see Figure 7-10 , the plate structure of all-ceramic, modular, and quick-installed wall panels, including a rectangular ceramic foam plate 1 vertically arranged, left and right, the thickness of the ceramic foam plate 1 is 20-25mm, and the front side of the ceramic foam plate 1 is pasted with The ceramic rock plate 2 matched with the foam ceramic plate 1, the thickness of the ceramic rock plate 2 is 3-6mm, the left and right sides of the foam ceramic plate 1 are provided with buckle grooves 5 arranged at intervals, and the shape of the buckle grooves 5 is arranged vertically The notch 51 of each buckle groove 5 is located in the lower half of the corresponding buckle groove 5, and the foam ceramic plate 1 is provided with a PVC plastic edge band 3, and the width of the PVC plastic edge band 3 just covers the foam ceramic plate 1, the ceramic rock plate 2, and the PVC plastic edge banding strip 3 are provided with corresponding openings corresponding to the notch 51 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap