Light-weight flexible non-woven material

A non-woven material and lightweight technology, applied in non-woven fabrics, textiles, papermaking, textiles, etc., can solve problems such as environmental pollution, poor forming degree, and secondary biodegradation of unfavorable materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

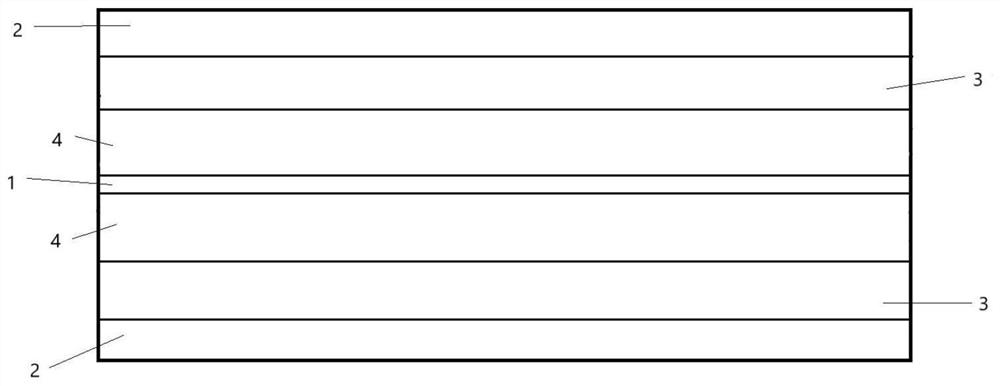

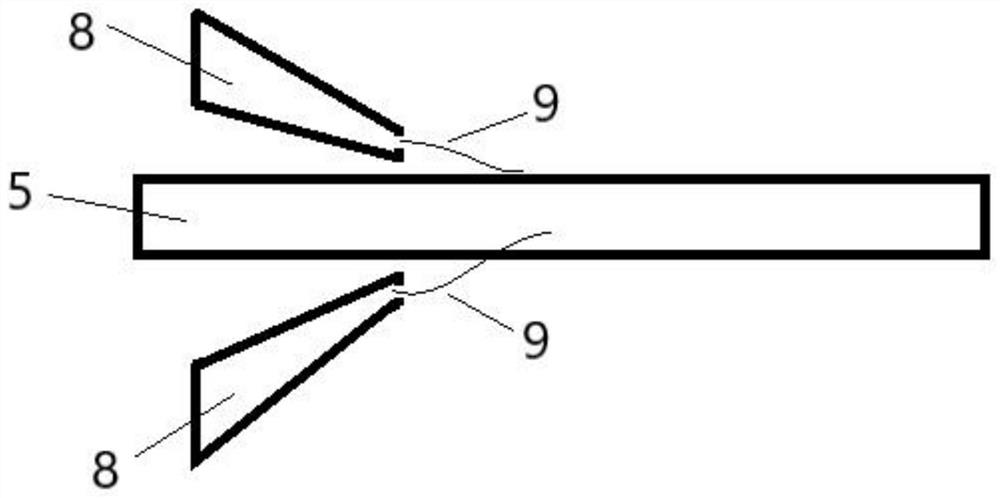

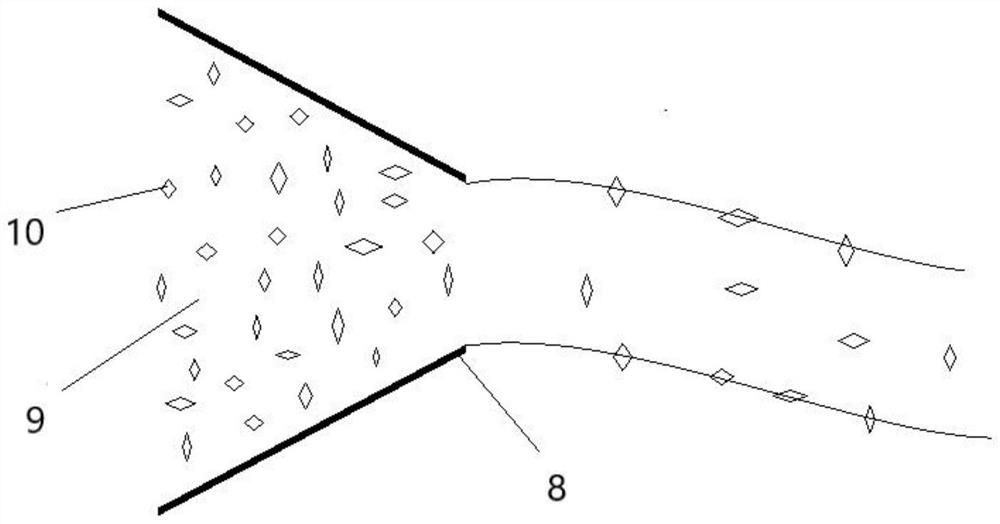

[0023] Such as figure 1 As shown, the lightweight flexible nonwoven material of the embodiment of the present invention includes a cloth layer 1, and a flexible glass layer 2, a fiber layer 3 and a nano-film layer 4 that are sequentially coated on the outside of the cloth layer 1 from the outside to the inside. Layer 1 is woven from a core-spun yarn material unit, and the core-spun yarn material unit includes a gas bag 5, and a nano-spun layer 6 and a coated fiber layer 7 positioned outside the gas bag 5; the gas bag 5 is made of antibacterial material; the gas bag 5 has an active damage function. Inert gas is filled in the gas bag 5 . Inert gases are free of moisture and microbial impurities.

[0024] Wherein, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com